Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

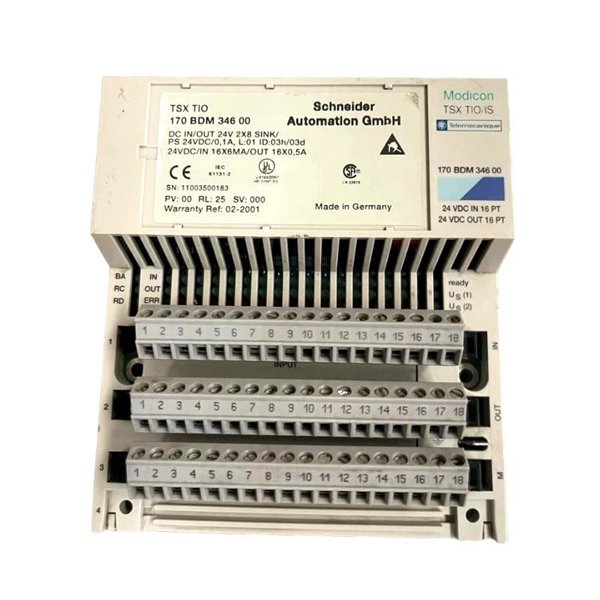

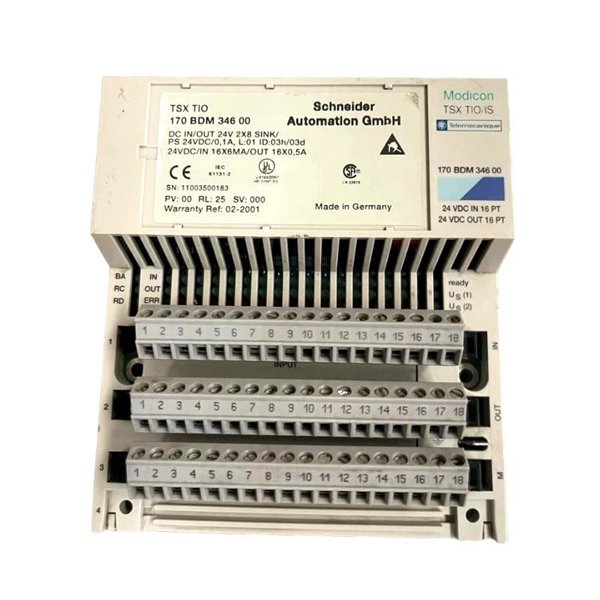

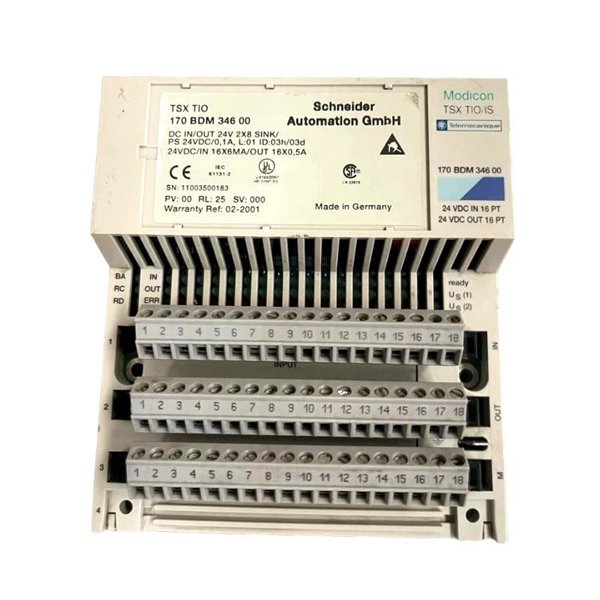

Schneider 170BDM34600 Input/Output Module

Manufacturer:Schneider

Product Number:170BDM34600

Product Type:Input/Output Module

Origin:France

Dimensions:125 x 40 x 180 mm

Weight:0.34 kg

Views:41

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Schneider Electric 170BDM34600 is a versatile 32-point discrete I/O module from the trusted Modicon Momentum series, designed to combine both digital input and output functions in a compact and efficient form. Specifically engineered for demanding industrial environments, this module provides 16 discrete inputs and 16 discrete outputs, all operating at 24 VDC. It allows efficient and economical data acquisition and control within decentralized architectures.

Ideal for space-constrained control panels, the 170BDM34600 seamlessly integrates with Momentum bases and communication adapters, forming part of a modular and scalable automation solution. The module supports high-speed digital communication, accurate signal acquisition, and reliable signal delivery to field devices—all within a rugged, DIN-rail mounted form factor.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 170BDM34600 |

| Manufacturer | Schneider Electric |

| Product Type | Discrete Input/Output Module |

| Series | Modicon Momentum |

| Input Channels | 16 discrete inputs |

| Output Channels | 16 discrete outputs |

| Input Voltage | 24 VDC sink type |

| Output Voltage | 24 VDC source type |

| Input Current per Point | 7 mA nominal |

| Output Current per Point | 0.5 A |

| Output Current Total | 8 A maximum (total for all channels) |

| Response Time | 1 ms ON / 1 ms OFF (input) |

| Diagnostics | Module-level diagnostics for input and output status |

| Status Indicators | LEDs for each 8-channel group (input/output separately) |

| Mounting Type | DIN rail (via Momentum base) |

| Power Supply | Via backplane through base module |

| Cable Length | 0.2 meters |

| Isolation | Optical isolation between logic and field points |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% non-condensing |

| Certifications | CE, UL, CSA, RoHS |

| Dimensions (W x H x D) | 125 x 40 x 180 mm |

| Weight | 0.34 kg |

Product Applications

The 170BDM34600 is well-suited for control and monitoring tasks that demand both digital input and output operations within a single compact module. Its applications span a wide array of industries, including:

Automotive Manufacturing: Controls robotic tooling and monitors safety switches and interlocks.

Food & Beverage: Interfaces with sensors and actuators for sorting, filling, and packing lines.

Material Handling Systems: Tracks conveyors, gates, and sensors while controlling motors or solenoids.

Water and Wastewater: Monitors limit switches and floats while managing relays or valves.

Textile Industry: Interfaces with pattern sensors, motion control devices, and stepper actuators.

Building Automation: Handles alarm system inputs and controls lighting, fans, or HVAC relays.

By combining both input and output capabilities, the module simplifies system design and reduces the need for separate modules and wiring.

Product Advantages

Dual-Functionality in One Module: Reduces module count and panel space by combining 16 inputs and 16 outputs.

High-Speed Signal Processing: 1 ms response time ensures fast detection and action for real-time systems.

LED Status Indicators: Built-in diagnostics provide immediate visual feedback, easing commissioning and troubleshooting.

Seamless Momentum Integration: Designed to plug directly into Modicon Momentum bases, simplifying deployment.

Field-Isolated Design: Optical isolation protects control logic from surges and electrical noise.

DIN Rail Friendly: Compact footprint ideal for modular and distributed control cabinets.

Low Power Requirements: Efficient design lowers heat output and energy use.

Backplane-Powered: Eliminates need for individual power wiring, reducing installation effort.

Robust Construction: Withstands vibration and temperature extremes, ideal for industrial environments.

Compatible with Major Networks: Easily integrates with Modbus, Ethernet, and other control networks through adapters.

Frequently Asked Questions (FAQ)

What type of input configuration does the 170BDM34600 support?

The module supports 24 VDC sink-type inputs, suitable for sourcing-type sensors.

What output type does the module provide?

It provides 24 VDC source-type outputs, capable of directly driving solenoids, relays, or indicator lamps.

Can the module be used for safety-critical inputs?

While not safety-certified, it can monitor safety devices if redundancy and external safety logic are employed.

Does this module support hot-swapping?

Yes, the 170BDM34600 supports hot-swap replacement when installed in a Momentum system with appropriate base.

Is signal debouncing available for the inputs?

Input filtering is handled by the controller or communication adapter configuration, not within the module itself.

What is the max current capacity of the output section?

Each output can handle up to 0.5 A, with a total module output capacity of 8 A.

How are the input/output points isolated?

Inputs and outputs are optically isolated from the control logic to reduce noise and prevent damage.

Can I connect both inductive and resistive loads to the outputs?

Yes, both types are supported; inductive loads should include flyback diodes for protection.

What is the recommended fuse rating for the output channels?

Use 0.5 A fast-blow or resettable fuses per output for optimal protection.

How does the module communicate with the PLC CPU?

Communication is handled via the Momentum base and communication adapter, such as Ethernet or Modbus TCP.

Schneider 170BDM34600 Input/Output Module

Manufacturer:Schneider

Product Number:170BDM34600

Product Type:Input/Output Module

Origin:France

Dimensions:125 x 40 x 180 mm

Weight:0.34 kg

Views:41

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Schneider Electric 170BDM34600 is a versatile 32-point discrete I/O module from the trusted Modicon Momentum series, designed to combine both digital input and output functions in a compact and efficient form. Specifically engineered for demanding industrial environments, this module provides 16 discrete inputs and 16 discrete outputs, all operating at 24 VDC. It allows efficient and economical data acquisition and control within decentralized architectures.

Ideal for space-constrained control panels, the 170BDM34600 seamlessly integrates with Momentum bases and communication adapters, forming part of a modular and scalable automation solution. The module supports high-speed digital communication, accurate signal acquisition, and reliable signal delivery to field devices—all within a rugged, DIN-rail mounted form factor.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 170BDM34600 |

| Manufacturer | Schneider Electric |

| Product Type | Discrete Input/Output Module |

| Series | Modicon Momentum |

| Input Channels | 16 discrete inputs |

| Output Channels | 16 discrete outputs |

| Input Voltage | 24 VDC sink type |

| Output Voltage | 24 VDC source type |

| Input Current per Point | 7 mA nominal |

| Output Current per Point | 0.5 A |

| Output Current Total | 8 A maximum (total for all channels) |

| Response Time | 1 ms ON / 1 ms OFF (input) |

| Diagnostics | Module-level diagnostics for input and output status |

| Status Indicators | LEDs for each 8-channel group (input/output separately) |

| Mounting Type | DIN rail (via Momentum base) |

| Power Supply | Via backplane through base module |

| Cable Length | 0.2 meters |

| Isolation | Optical isolation between logic and field points |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% non-condensing |

| Certifications | CE, UL, CSA, RoHS |

| Dimensions (W x H x D) | 125 x 40 x 180 mm |

| Weight | 0.34 kg |

Product Applications

The 170BDM34600 is well-suited for control and monitoring tasks that demand both digital input and output operations within a single compact module. Its applications span a wide array of industries, including:

Automotive Manufacturing: Controls robotic tooling and monitors safety switches and interlocks.

Food & Beverage: Interfaces with sensors and actuators for sorting, filling, and packing lines.

Material Handling Systems: Tracks conveyors, gates, and sensors while controlling motors or solenoids.

Water and Wastewater: Monitors limit switches and floats while managing relays or valves.

Textile Industry: Interfaces with pattern sensors, motion control devices, and stepper actuators.

Building Automation: Handles alarm system inputs and controls lighting, fans, or HVAC relays.

By combining both input and output capabilities, the module simplifies system design and reduces the need for separate modules and wiring.

Product Advantages

Dual-Functionality in One Module: Reduces module count and panel space by combining 16 inputs and 16 outputs.

High-Speed Signal Processing: 1 ms response time ensures fast detection and action for real-time systems.

LED Status Indicators: Built-in diagnostics provide immediate visual feedback, easing commissioning and troubleshooting.

Seamless Momentum Integration: Designed to plug directly into Modicon Momentum bases, simplifying deployment.

Field-Isolated Design: Optical isolation protects control logic from surges and electrical noise.

DIN Rail Friendly: Compact footprint ideal for modular and distributed control cabinets.

Low Power Requirements: Efficient design lowers heat output and energy use.

Backplane-Powered: Eliminates need for individual power wiring, reducing installation effort.

Robust Construction: Withstands vibration and temperature extremes, ideal for industrial environments.

Compatible with Major Networks: Easily integrates with Modbus, Ethernet, and other control networks through adapters.

Frequently Asked Questions (FAQ)

What type of input configuration does the 170BDM34600 support?

The module supports 24 VDC sink-type inputs, suitable for sourcing-type sensors.

What output type does the module provide?

It provides 24 VDC source-type outputs, capable of directly driving solenoids, relays, or indicator lamps.

Can the module be used for safety-critical inputs?

While not safety-certified, it can monitor safety devices if redundancy and external safety logic are employed.

Does this module support hot-swapping?

Yes, the 170BDM34600 supports hot-swap replacement when installed in a Momentum system with appropriate base.

Is signal debouncing available for the inputs?

Input filtering is handled by the controller or communication adapter configuration, not within the module itself.

What is the max current capacity of the output section?

Each output can handle up to 0.5 A, with a total module output capacity of 8 A.

How are the input/output points isolated?

Inputs and outputs are optically isolated from the control logic to reduce noise and prevent damage.

Can I connect both inductive and resistive loads to the outputs?

Yes, both types are supported; inductive loads should include flyback diodes for protection.

What is the recommended fuse rating for the output channels?

Use 0.5 A fast-blow or resettable fuses per output for optimal protection.

How does the module communicate with the PLC CPU?

Communication is handled via the Momentum base and communication adapter, such as Ethernet or Modbus TCP.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...