Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

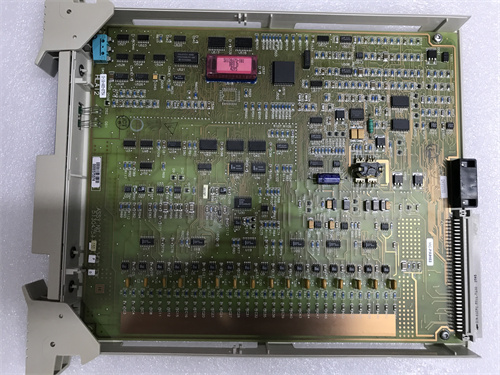

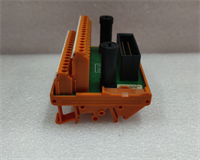

Honeywell 621-3502 Input Module

Manufacturer:Honeywell

Product Number:621-3502

Product Type:Input Module

Origin:Sweden

Dimensions:158 x 47 x 108 mm

Weight:0.522 kg

Views:47

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell 621-3502 Input Module is a vital component within Honeywell’s TDC 3000 Distributed Control System (DCS), designed specifically for acquiring analog input signals from field devices. This module translates real-world analog signals into digital data that can be processed by the control system, enabling precise monitoring and control of industrial processes.

Built for industrial environments, the 621-3502 Input Module supports multiple analog channels, offering high accuracy, signal isolation, and robust diagnostics to ensure reliable data acquisition. Its modular design and compact footprint allow for easy installation and maintenance in control cabinets.

The 621-3502 plays an essential role in industries such as oil and gas, power generation, chemical manufacturing, and water treatment, where precise and reliable process measurements are critical for operational safety and efficiency.

Technical Specifications

| Parameter | Details |

|---|---|

| Product Name | Analog Input Module |

| Model Number | 621-3502 |

| Brand | Honeywell |

| System Compatibility | TDC 3000 |

| Number of Input Channels | 8 analog inputs |

| Input Signal Type | 4-20 mA, 0-20 mA, voltage inputs |

| Input Range | 0-24 mA, 0-10 V (software configurable) |

| Input Accuracy | ±0.1% of full scale |

| Input Isolation | Galvanic isolation per channel |

| Input Impedance | >250 ohms (current),>1 MΩ (voltage) |

| Conversion Time | ≤ 10 ms per channel |

| Power Supply Voltage | 24 VDC regulated |

| Mounting Type | Rack-mounted |

| Operating Temperature | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature | -40°C to 85°C |

| Humidity | 5% to 95% non-condensing |

| Protection Rating | IP20 (cabinet installation) |

| Dimensions (L × W × H) | 158 x 47 x 108 mm |

| Weight | 0.522 kg |

| Certifications | CE, RoHS, UL certified |

Applications

The Honeywell 621-3502 Input Module is suited for a wide range of industrial applications, including:

Oil & Gas Industry: Measuring pressure, temperature, and flow through analog transmitters to ensure safe and efficient production.

Power Plants: Monitoring boiler parameters, turbine conditions, and auxiliary system instrumentation.

Chemical Manufacturing: Precise measurement of process variables critical to chemical reactions and batch processes.

Water and Wastewater Treatment: Control of pumps, valves, and chemical dosing through accurate analog feedback.

Pharmaceutical Production: Maintaining strict control over process variables for compliance and quality assurance.

Pulp and Paper Mills: Measuring moisture, pressure, and temperature to optimize production quality and efficiency.

Product Advantages

High Accuracy and Stability: Ensures reliable data collection with minimal drift over time.

Galvanic Isolation: Protects the system from electrical noise and faults, improving signal integrity.

Flexible Input Types: Supports a variety of analog signal standards (current and voltage).

Robust Diagnostics: Enables early detection of wiring faults or sensor failures.

Compact and Modular: Fits neatly into Honeywell’s TDC 3000 racks, simplifying system expansion and maintenance.

Industry Certifications: Meets stringent global standards for industrial automation equipment.

Frequently Asked Questions (FAQ)

1. What types of analog signals can the 621-3502 module process?

It supports current inputs (4-20 mA, 0-20 mA) and voltage inputs (0-10 V), configurable via software.

2. How many channels does the module have?

There are 8 analog input channels per module.

3. Is each channel electrically isolated?

Yes, each channel features galvanic isolation to prevent cross-talk and protect system components.

4. Can this module work with the latest Honeywell control systems?

It is designed for the TDC 3000 system; compatibility with newer platforms may require additional hardware.

5. What kind of diagnostics does the module offer?

It provides fault detection for wiring errors, open sensors, and signal out-of-range conditions.

6. What is the typical response time for inputs?

The module converts analog signals within 10 milliseconds per channel.

7. How is the module mounted?

It is rack-mounted and installed in a standard Honeywell I/O cabinet.

8. What power supply voltage does the module require?

A regulated 24 VDC power supply is necessary.

9. Is the module suitable for harsh industrial environments?

Yes, it operates reliably between 0°C and 60°C and can tolerate up to 95% non-condensing humidity.

10. What happens if a channel fails?

The module’s diagnostics will alert operators of faults, enabling prompt troubleshooting and replacement if needed.

Honeywell 621-3502 Input Module

Manufacturer:Honeywell

Product Number:621-3502

Product Type:Input Module

Origin:Sweden

Dimensions:158 x 47 x 108 mm

Weight:0.522 kg

Views:47

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell 621-3502 Input Module is a vital component within Honeywell’s TDC 3000 Distributed Control System (DCS), designed specifically for acquiring analog input signals from field devices. This module translates real-world analog signals into digital data that can be processed by the control system, enabling precise monitoring and control of industrial processes.

Built for industrial environments, the 621-3502 Input Module supports multiple analog channels, offering high accuracy, signal isolation, and robust diagnostics to ensure reliable data acquisition. Its modular design and compact footprint allow for easy installation and maintenance in control cabinets.

The 621-3502 plays an essential role in industries such as oil and gas, power generation, chemical manufacturing, and water treatment, where precise and reliable process measurements are critical for operational safety and efficiency.

Technical Specifications

| Parameter | Details |

|---|---|

| Product Name | Analog Input Module |

| Model Number | 621-3502 |

| Brand | Honeywell |

| System Compatibility | TDC 3000 |

| Number of Input Channels | 8 analog inputs |

| Input Signal Type | 4-20 mA, 0-20 mA, voltage inputs |

| Input Range | 0-24 mA, 0-10 V (software configurable) |

| Input Accuracy | ±0.1% of full scale |

| Input Isolation | Galvanic isolation per channel |

| Input Impedance | >250 ohms (current),>1 MΩ (voltage) |

| Conversion Time | ≤ 10 ms per channel |

| Power Supply Voltage | 24 VDC regulated |

| Mounting Type | Rack-mounted |

| Operating Temperature | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature | -40°C to 85°C |

| Humidity | 5% to 95% non-condensing |

| Protection Rating | IP20 (cabinet installation) |

| Dimensions (L × W × H) | 158 x 47 x 108 mm |

| Weight | 0.522 kg |

| Certifications | CE, RoHS, UL certified |

Applications

The Honeywell 621-3502 Input Module is suited for a wide range of industrial applications, including:

Oil & Gas Industry: Measuring pressure, temperature, and flow through analog transmitters to ensure safe and efficient production.

Power Plants: Monitoring boiler parameters, turbine conditions, and auxiliary system instrumentation.

Chemical Manufacturing: Precise measurement of process variables critical to chemical reactions and batch processes.

Water and Wastewater Treatment: Control of pumps, valves, and chemical dosing through accurate analog feedback.

Pharmaceutical Production: Maintaining strict control over process variables for compliance and quality assurance.

Pulp and Paper Mills: Measuring moisture, pressure, and temperature to optimize production quality and efficiency.

Product Advantages

High Accuracy and Stability: Ensures reliable data collection with minimal drift over time.

Galvanic Isolation: Protects the system from electrical noise and faults, improving signal integrity.

Flexible Input Types: Supports a variety of analog signal standards (current and voltage).

Robust Diagnostics: Enables early detection of wiring faults or sensor failures.

Compact and Modular: Fits neatly into Honeywell’s TDC 3000 racks, simplifying system expansion and maintenance.

Industry Certifications: Meets stringent global standards for industrial automation equipment.

Frequently Asked Questions (FAQ)

1. What types of analog signals can the 621-3502 module process?

It supports current inputs (4-20 mA, 0-20 mA) and voltage inputs (0-10 V), configurable via software.

2. How many channels does the module have?

There are 8 analog input channels per module.

3. Is each channel electrically isolated?

Yes, each channel features galvanic isolation to prevent cross-talk and protect system components.

4. Can this module work with the latest Honeywell control systems?

It is designed for the TDC 3000 system; compatibility with newer platforms may require additional hardware.

5. What kind of diagnostics does the module offer?

It provides fault detection for wiring errors, open sensors, and signal out-of-range conditions.

6. What is the typical response time for inputs?

The module converts analog signals within 10 milliseconds per channel.

7. How is the module mounted?

It is rack-mounted and installed in a standard Honeywell I/O cabinet.

8. What power supply voltage does the module require?

A regulated 24 VDC power supply is necessary.

9. Is the module suitable for harsh industrial environments?

Yes, it operates reliably between 0°C and 60°C and can tolerate up to 95% non-condensing humidity.

10. What happens if a channel fails?

The module’s diagnostics will alert operators of faults, enabling prompt troubleshooting and replacement if needed.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...