Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

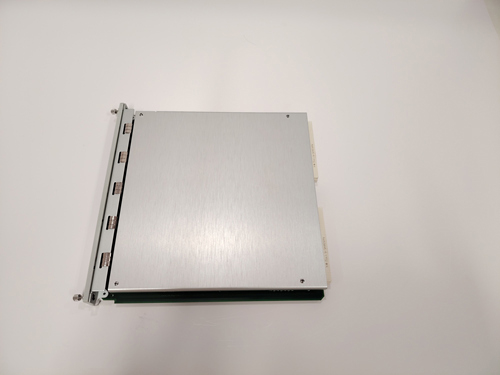

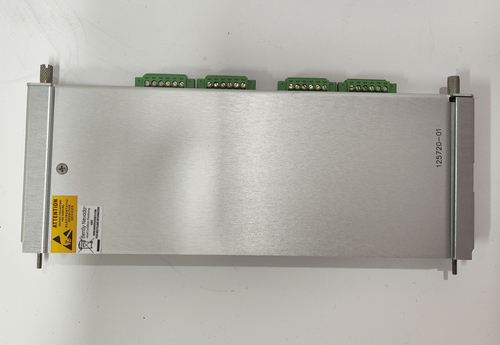

Bently Nevada 330780-51-00 Proximity Sensor

Brand:Bently Nevada

Model Number:330780-51-00

Type:Proximity Sensor

Product Origin:USA

Payment:T/T, Western Union, Credit Card

Dimensions:155 x 136 x 119 mm

Weight:280g

Price:USD87

Certificate:CE

Warranty:1 years

Product Description

The Bently Nevada 330780-51-00 is a proximity sensor specifically designed for non-contact displacement and vibration measurements. It is part of the Bently Nevada 3300 XL series and is commonly used in industrial applications, particularly in rotating machinery monitoring systems.

Key Features

- Non-contact measurement: This sensor eliminates physical contact with the target, ensuring long-term reliability and reducing wear.

- High sensitivity: It accurately detects even small changes in displacement or vibration, making it ideal for precise monitoring.

- Robust construction: The sensor’s durable design withstands harsh industrial environments, ensuring consistent performance.

- Wide frequency range: This sensor measures a broad spectrum of frequencies, enhancing its versatility.

- Compatibility: It seamlessly integrates with other components in the Bently Nevada monitoring system, simplifying installation and use.

Technical Specifications

- Sensor type: Eddy current proximity sensor

- Nominal measurement range: Typically 0.5 mm to 4.5 mm (20 mils to 180 mils)

- Frequency response: Varies by configuration but generally covers a wide range

- Output signal: Voltage

- Operating temperature: -20°C to +85°C

- Cable length: 5 meters (16.4 feet)

- Mounting: Panel or guide rail mounting options

- Approvals: Various certifications for use across different industries and regions

Applications

- Radial vibration and displacement: Measure the vibration of rotating shafts and bearings to monitor their condition.

- Axial displacement: Monitor shaft axial movement for precise machinery alignment.

- Key phase measurement: Assess the alignment of rotating components to ensure optimal performance.

- Condition monitoring: Detect early signs of machinery wear or imbalance, enabling proactive maintenance.

Bently Nevada 330780-51-00 Proximity Sensor

Brand:Bently Nevada

Model Number:330780-51-00

Type:Proximity Sensor

Product Origin:USA

Payment:T/T, Western Union, Credit Card

Dimensions:155 x 136 x 119 mm

Weight:280g

Price:USD87

Certificate:CE

Warranty:1 years

Product Description

The Bently Nevada 330780-51-00 is a proximity sensor specifically designed for non-contact displacement and vibration measurements. It is part of the Bently Nevada 3300 XL series and is commonly used in industrial applications, particularly in rotating machinery monitoring systems.

Key Features

- Non-contact measurement: This sensor eliminates physical contact with the target, ensuring long-term reliability and reducing wear.

- High sensitivity: It accurately detects even small changes in displacement or vibration, making it ideal for precise monitoring.

- Robust construction: The sensor’s durable design withstands harsh industrial environments, ensuring consistent performance.

- Wide frequency range: This sensor measures a broad spectrum of frequencies, enhancing its versatility.

- Compatibility: It seamlessly integrates with other components in the Bently Nevada monitoring system, simplifying installation and use.

Technical Specifications

- Sensor type: Eddy current proximity sensor

- Nominal measurement range: Typically 0.5 mm to 4.5 mm (20 mils to 180 mils)

- Frequency response: Varies by configuration but generally covers a wide range

- Output signal: Voltage

- Operating temperature: -20°C to +85°C

- Cable length: 5 meters (16.4 feet)

- Mounting: Panel or guide rail mounting options

- Approvals: Various certifications for use across different industries and regions

Applications

- Radial vibration and displacement: Measure the vibration of rotating shafts and bearings to monitor their condition.

- Axial displacement: Monitor shaft axial movement for precise machinery alignment.

- Key phase measurement: Assess the alignment of rotating components to ensure optimal performance.

- Condition monitoring: Detect early signs of machinery wear or imbalance, enabling proactive maintenance.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...