Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

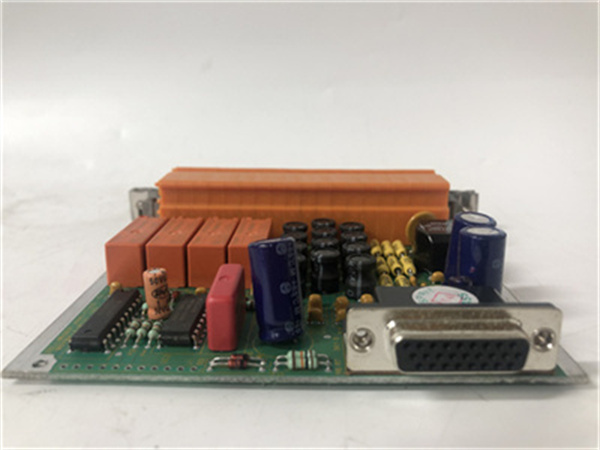

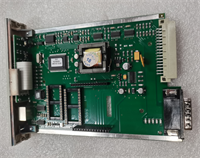

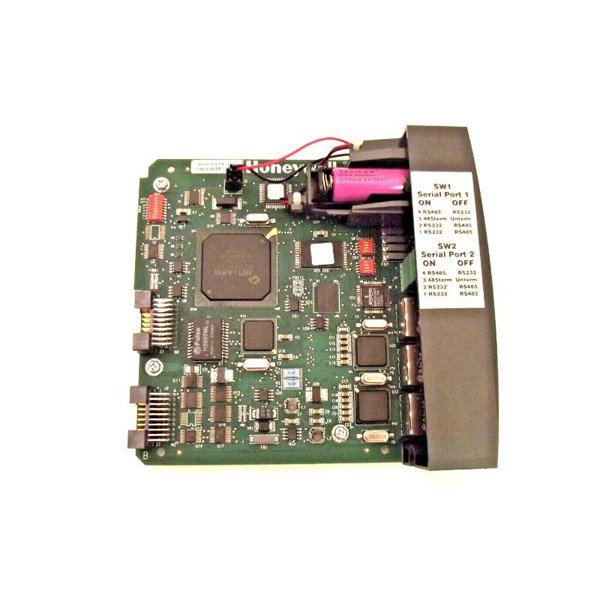

Honeywell 900C71R-0000-10 Controller C70 CPU Module

Manufacturer:Honeywell

Product Number:900C71R-0000-10

Product Type:Controller C70 CPU Module

Origin:USA

Dimensions:137 × 38.1 × 151.7 mm

Weight:0.4 kg

Views:51

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

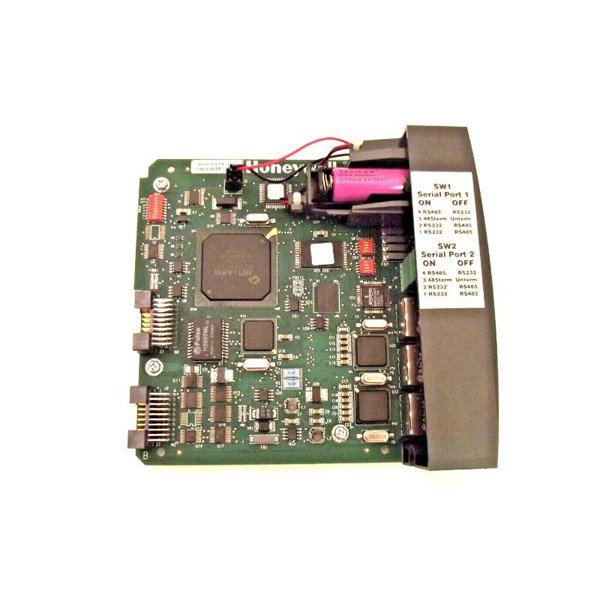

The Honeywell 900C71R-0000-10 is a C70 CPU module designed for use in the Honeywell HC900 Hybrid Control System. As a core processing unit, it combines advanced logic, loop, and sequencing control in one module, supporting both non-redundant and redundant configurations. With built-in Ethernet communication, serial ports, and scalable architecture, it offers high flexibility and robustness for process automation.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 900C71R-0000-10 |

| Product Type | C70 CPU Module (Redundant capable) |

| CPU Type | 32-bit with battery-backed real-time clock |

| Serial Ports | 2 × RS-232/RS-485 (legacy), RS-485 (new systems) |

| Ethernet Ports | 2 × 10/100Base-T for host communication |

| Memory | Flash memory for firmware and configurations |

| Communication Protocols | Modbus TCP, Modbus RTU |

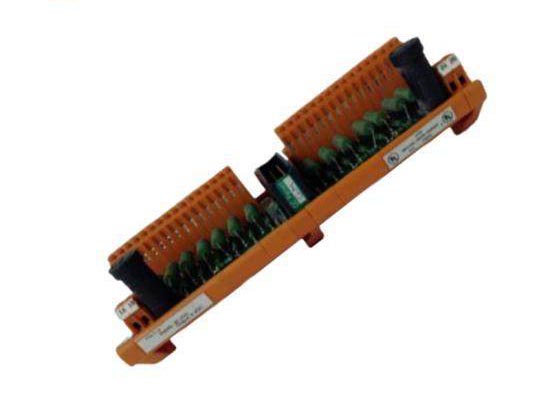

| Compatible I/O | Remote via Scanner 2 modules (900C73R) |

| Redundancy Support | Yes (with Redundancy Switch Module) |

| Power Supply | Supplied via rack (P01/P02/P24) |

| Installation Rack | HC900 controller rack (4, 8, or 12 slot) |

| Dimensions (H × W × D) | 137 × 38.1 × 151.7 mm |

| Weight | 0.4 kg |

Applications

-

Industrial process control

-

Thermal processing systems (furnaces, kilns)

-

Water and wastewater treatment plants

-

Batch and continuous manufacturing

-

Safety interlock and alarm systems (when used in SIL-certified systems)

-

SCADA and HMI integration for real-time control

Advantages

Flexible architecture: Supports modular system expansion with remote I/O.

Redundancy-ready: Ensures system availability in mission-critical applications.

Versatile communication: Dual Ethernet ports and serial interfaces.

Scalable control: Suitable for both small and medium-scale operations.

Modbus support: Integrates easily with third-party systems.

Rugged design: Reliable performance in industrial environments.

FAQ

Q1: What is the purpose of the Honeywell 900C71R-0000-10 module?

A1: It acts as the central processing unit in HC900 systems, handling control logic, data acquisition, and communication.

Q2: Does this model support redundancy?

A2: Yes, it supports redundant configurations with an RSM (Redundancy Switch Module) and a paired CPU.

Q3: What type of communication ports are available?

A3: It features 2 Ethernet ports for host communication and 2 serial ports (RS-232/RS-485).

Q4: Can I connect local I/O modules directly to the C70 CPU?

A4: No, all I/O for the C70 must be remote, connected via Ethernet through Scanner 2 modules.

Q5: Is this module compatible with the new SIL-rated systems?

A5: No, this model is for legacy systems. SIL-rated equivalents are available under different part numbers.

Q6: What kind of power supply is required?

A6: It is powered via a Honeywell rack using models like 900P01 or 900P02 power supplies.

Q7: What configuration tools are compatible?

A7: Honeywell HC Designer Software is used for configuration and diagnostics.

Q8: Is hot-swapping supported for the CPU?

A8: No, the CPU module must be powered down before removal or replacement.

Q9: How many I/O racks can be connected to a C70 CPU?

A9: Up to four I/O expansion racks via a private Ethernet network.

Q10: What kind of applications is this CPU best suited for?

A10: It is ideal for industrial automation in processes requiring precise and reliable control.

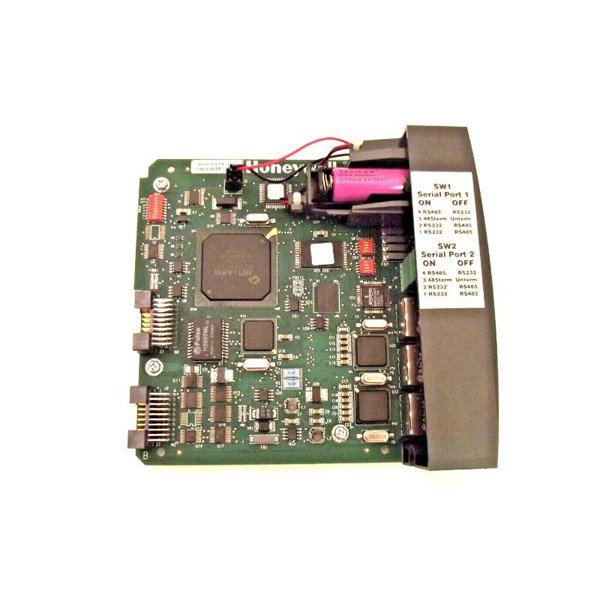

Honeywell 900C71R-0000-10 Controller C70 CPU Module

Manufacturer:Honeywell

Product Number:900C71R-0000-10

Product Type:Controller C70 CPU Module

Origin:USA

Dimensions:137 × 38.1 × 151.7 mm

Weight:0.4 kg

Views:51

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell 900C71R-0000-10 is a C70 CPU module designed for use in the Honeywell HC900 Hybrid Control System. As a core processing unit, it combines advanced logic, loop, and sequencing control in one module, supporting both non-redundant and redundant configurations. With built-in Ethernet communication, serial ports, and scalable architecture, it offers high flexibility and robustness for process automation.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 900C71R-0000-10 |

| Product Type | C70 CPU Module (Redundant capable) |

| CPU Type | 32-bit with battery-backed real-time clock |

| Serial Ports | 2 × RS-232/RS-485 (legacy), RS-485 (new systems) |

| Ethernet Ports | 2 × 10/100Base-T for host communication |

| Memory | Flash memory for firmware and configurations |

| Communication Protocols | Modbus TCP, Modbus RTU |

| Compatible I/O | Remote via Scanner 2 modules (900C73R) |

| Redundancy Support | Yes (with Redundancy Switch Module) |

| Power Supply | Supplied via rack (P01/P02/P24) |

| Installation Rack | HC900 controller rack (4, 8, or 12 slot) |

| Dimensions (H × W × D) | 137 × 38.1 × 151.7 mm |

| Weight | 0.4 kg |

Applications

-

Industrial process control

-

Thermal processing systems (furnaces, kilns)

-

Water and wastewater treatment plants

-

Batch and continuous manufacturing

-

Safety interlock and alarm systems (when used in SIL-certified systems)

-

SCADA and HMI integration for real-time control

Advantages

Flexible architecture: Supports modular system expansion with remote I/O.

Redundancy-ready: Ensures system availability in mission-critical applications.

Versatile communication: Dual Ethernet ports and serial interfaces.

Scalable control: Suitable for both small and medium-scale operations.

Modbus support: Integrates easily with third-party systems.

Rugged design: Reliable performance in industrial environments.

FAQ

Q1: What is the purpose of the Honeywell 900C71R-0000-10 module?

A1: It acts as the central processing unit in HC900 systems, handling control logic, data acquisition, and communication.

Q2: Does this model support redundancy?

A2: Yes, it supports redundant configurations with an RSM (Redundancy Switch Module) and a paired CPU.

Q3: What type of communication ports are available?

A3: It features 2 Ethernet ports for host communication and 2 serial ports (RS-232/RS-485).

Q4: Can I connect local I/O modules directly to the C70 CPU?

A4: No, all I/O for the C70 must be remote, connected via Ethernet through Scanner 2 modules.

Q5: Is this module compatible with the new SIL-rated systems?

A5: No, this model is for legacy systems. SIL-rated equivalents are available under different part numbers.

Q6: What kind of power supply is required?

A6: It is powered via a Honeywell rack using models like 900P01 or 900P02 power supplies.

Q7: What configuration tools are compatible?

A7: Honeywell HC Designer Software is used for configuration and diagnostics.

Q8: Is hot-swapping supported for the CPU?

A8: No, the CPU module must be powered down before removal or replacement.

Q9: How many I/O racks can be connected to a C70 CPU?

A9: Up to four I/O expansion racks via a private Ethernet network.

Q10: What kind of applications is this CPU best suited for?

A10: It is ideal for industrial automation in processes requiring precise and reliable control.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...