Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

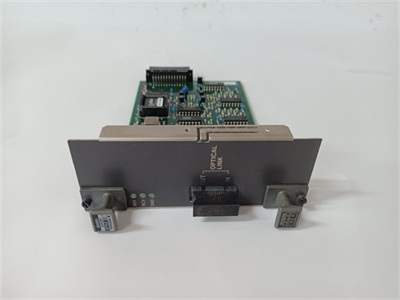

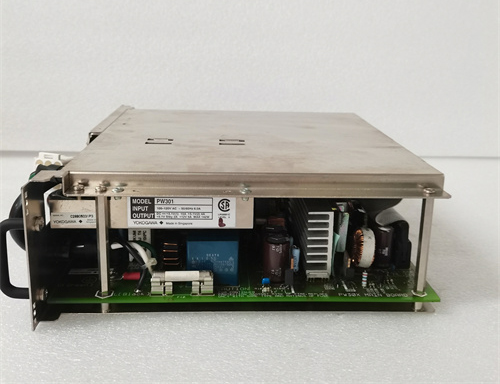

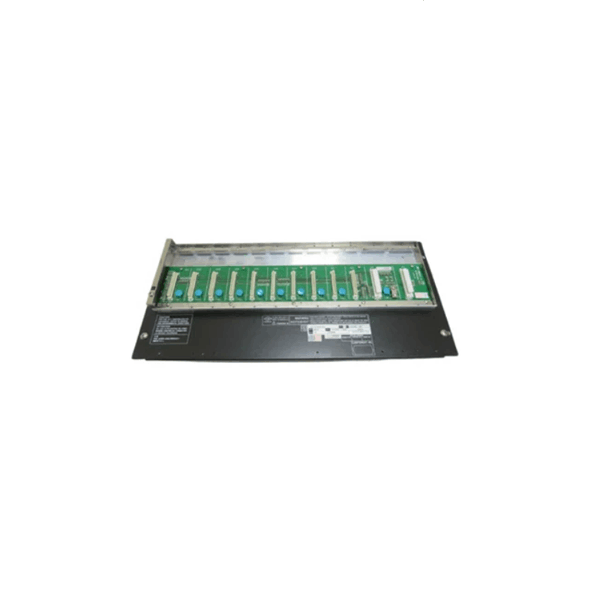

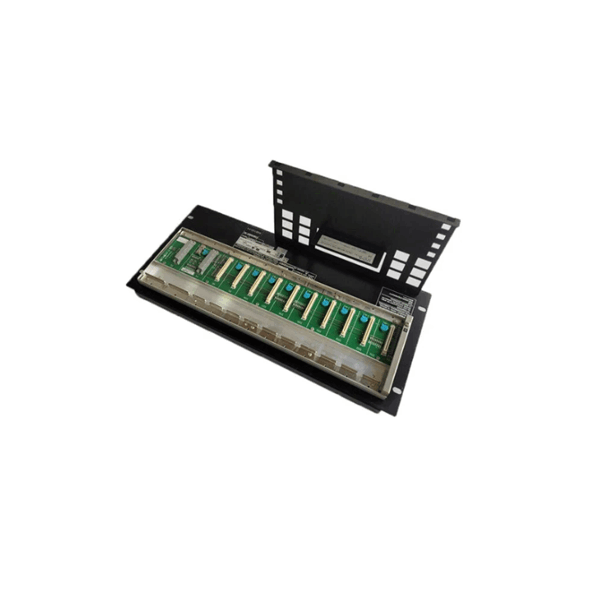

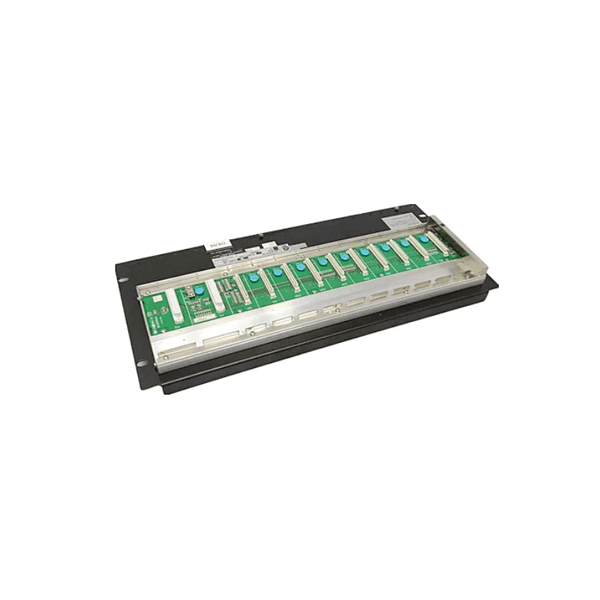

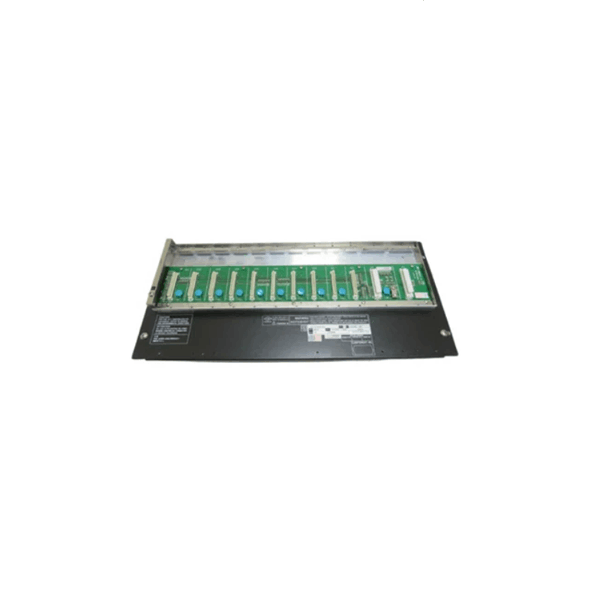

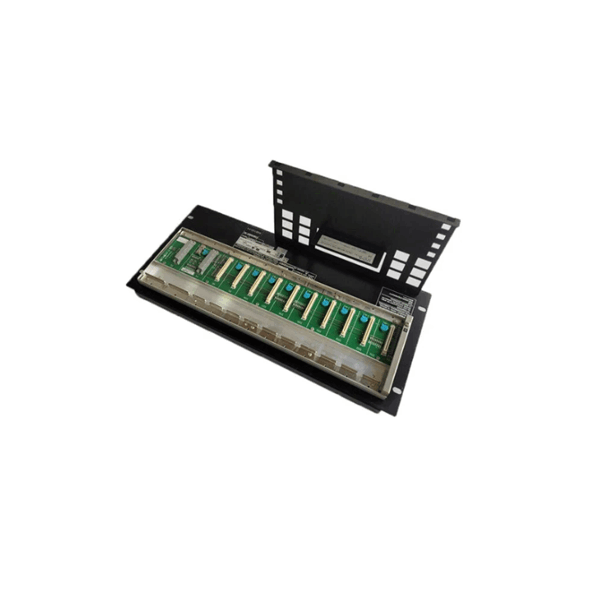

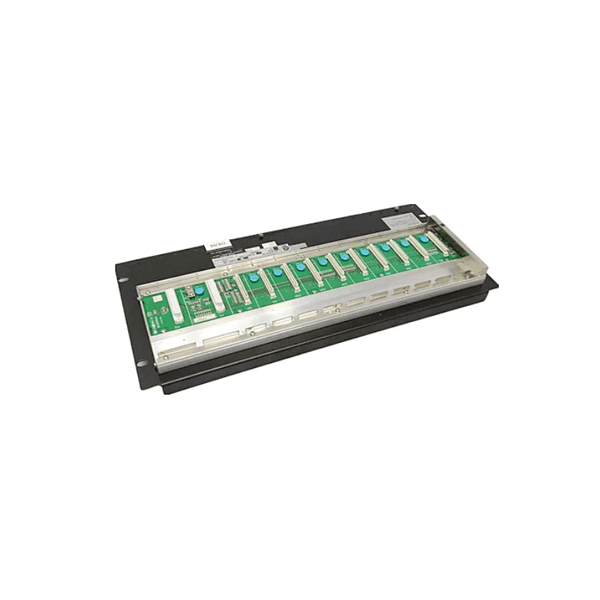

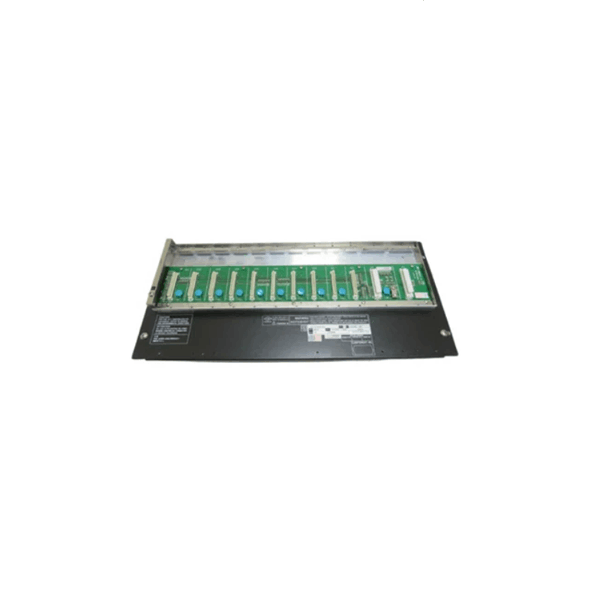

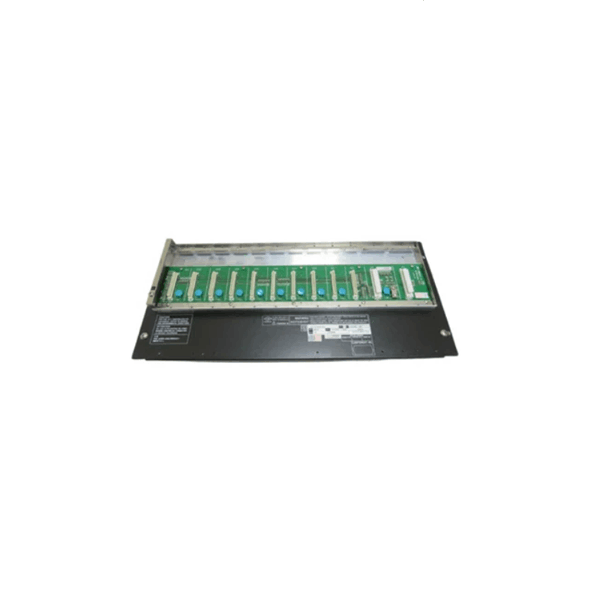

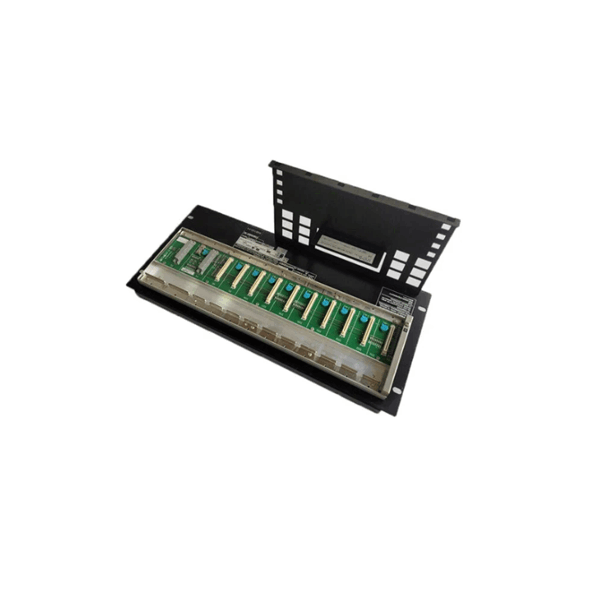

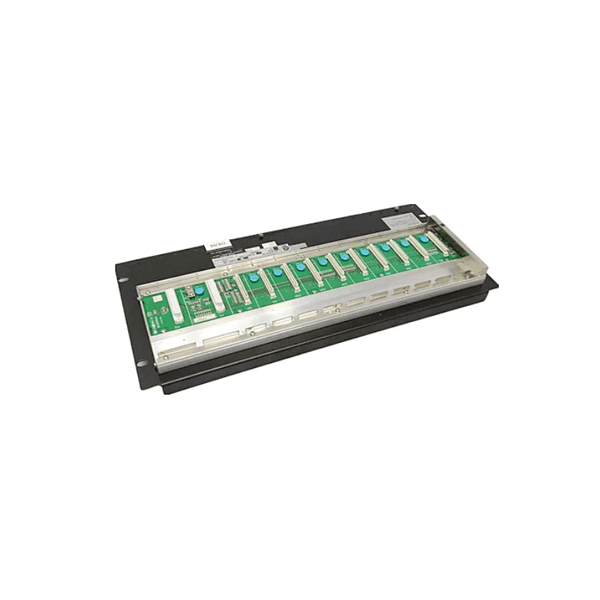

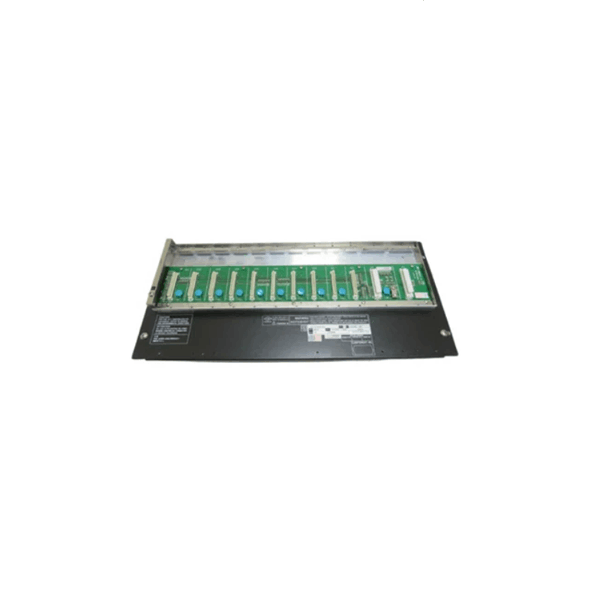

Yokogawa ANB10D ESB Bus Node Unit

Manufacturer:Yokogawa

Product Number:ANB10D

Condition:ESB Bus Node Unit

Origin:Japan

Dimensions:482.6 × 221.5 ×205 mm

Weight:10 kg

Views:38

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa ANB10D is a high-performance I/O module designed for integration within the CENTUM CS 3000 and CENTUM VP distributed control systems (DCS). As part of Yokogawa’s field-proven automation platform, the ANB10D serves as a remote I/O base unit, connecting multiple I/O modules and enabling reliable communication with the system’s controllers. It is engineered to meet rigorous industrial requirements and is widely utilized in industries such as oil & gas, petrochemicals, energy, water treatment, and manufacturing.

The ANB10D supports a wide range of analog and digital I/O modules, ensuring scalability, redundancy, and flexibility. With durable design and compact architecture, the module helps streamline control room wiring while enhancing system responsiveness.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | ANB10D |

| Type | Remote I/O Base Unit |

| System Compatibility | CENTUM CS 3000 / CENTUM VP |

| Power Supply Voltage | 24 VDC (nominal), 18–32 VDC operating range |

| Power Consumption | Max. 7.5 W |

| Mounting Type | DIN rail or panel mounting |

| Number of I/O Slots | 10 slots |

| Communication Interface | Vnet/IP |

| Redundancy Support | Yes (via dual communication paths) |

| Operating Temperature | 0°C to +55°C |

| Storage Temperature | -40°C to +70°C |

| Humidity Range | 5% to 95% RH (non-condensing) |

| Dimensions | 482.6 × 221.5 ×205 mm |

| Weight | 10 kg |

| Certifications | CE, CSA, KC, UL |

Product Applications

The Yokogawa ANB10D is designed for industrial environments where robust and scalable remote I/O management is necessary. Common applications include:

Petrochemical plants: For managing process instrumentation and field devices remotely.

Power generation facilities: To support turbine and generator control systems.

Oil & gas refineries: For pipeline automation, compressor station control.

Water and wastewater treatment plants: Monitoring flow, pressure, and chemical dosing systems.

Pharmaceutical manufacturing: For precise process control and compliance tracking.

General manufacturing: Integration with automation machinery and sensors.

Key Advantages

High Channel Density

The ANB10D supports up to 10 I/O modules in a single base, providing significant space and wiring savings.

Modular and Scalable Architecture

Easily expandable to match growing plant requirements without changing system infrastructure.

Reliable Communication via Vnet/IP

Ensures deterministic, high-speed, and redundant communication between controllers and I/O.

Strong Environmental Tolerance

Suitable for harsh industrial conditions with wide temperature and humidity tolerances.

Support for Redundant Systems

Enables high availability through dual communication paths and redundant module configuration.

Easy Installation and Maintenance

Designed for fast module replacement and minimal system downtime.

Compliance with Global Standards

Certified to meet CE, CSA, and other industrial standards, enhancing global applicability.

FAQ

Q1: What systems is the ANB10D compatible with?

A1: The ANB10D is fully compatible with Yokogawa CENTUM CS 3000 and CENTUM VP distributed control systems.

Q2: How many I/O modules can be installed on one ANB10D base unit?

A2: It supports up to 10 I/O modules on a single base.

Q3: Can I use ANB10D in high-vibration or dusty environments?

A3: Yes, its robust design and industrial-grade casing make it suitable for demanding environmental conditions.

Q4: Is hot-swapping of I/O modules supported?

A4: Yes, modules can be replaced without shutting down the system, minimizing downtime.

Q5: Does the ANB10D support redundant power supply configurations?

A5: Yes, it allows for redundant power input setups for enhanced reliability.

Q6: What type of communication protocol does it use?

A6: It uses Yokogawa’s Vnet/IP protocol for high-speed real-time control communication.

Q7: How does the ANB10D handle failures in I/O modules?

A7: The system detects faulty modules and can alert operators while maintaining system integrity.

Q8: Can the unit be mounted on both DIN rail and panels?

A8: Yes, the ANB10D supports both DIN rail and panel mount installation.

Q9: How is firmware updated on the ANB10D?

A9: Firmware updates are managed through the central system configuration tools provided by Yokogawa.

Q10: Is ANB10D suitable for use in SIL-rated systems?

A10: While it is highly reliable, users must verify compliance with specific SIL (Safety Integrity Level) requirements based on their application.

Yokogawa ANB10D ESB Bus Node Unit

Manufacturer:Yokogawa

Product Number:ANB10D

Condition:ESB Bus Node Unit

Origin:Japan

Dimensions:482.6 × 221.5 ×205 mm

Weight:10 kg

Views:38

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa ANB10D is a high-performance I/O module designed for integration within the CENTUM CS 3000 and CENTUM VP distributed control systems (DCS). As part of Yokogawa’s field-proven automation platform, the ANB10D serves as a remote I/O base unit, connecting multiple I/O modules and enabling reliable communication with the system’s controllers. It is engineered to meet rigorous industrial requirements and is widely utilized in industries such as oil & gas, petrochemicals, energy, water treatment, and manufacturing.

The ANB10D supports a wide range of analog and digital I/O modules, ensuring scalability, redundancy, and flexibility. With durable design and compact architecture, the module helps streamline control room wiring while enhancing system responsiveness.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | ANB10D |

| Type | Remote I/O Base Unit |

| System Compatibility | CENTUM CS 3000 / CENTUM VP |

| Power Supply Voltage | 24 VDC (nominal), 18–32 VDC operating range |

| Power Consumption | Max. 7.5 W |

| Mounting Type | DIN rail or panel mounting |

| Number of I/O Slots | 10 slots |

| Communication Interface | Vnet/IP |

| Redundancy Support | Yes (via dual communication paths) |

| Operating Temperature | 0°C to +55°C |

| Storage Temperature | -40°C to +70°C |

| Humidity Range | 5% to 95% RH (non-condensing) |

| Dimensions | 482.6 × 221.5 ×205 mm |

| Weight | 10 kg |

| Certifications | CE, CSA, KC, UL |

Product Applications

The Yokogawa ANB10D is designed for industrial environments where robust and scalable remote I/O management is necessary. Common applications include:

Petrochemical plants: For managing process instrumentation and field devices remotely.

Power generation facilities: To support turbine and generator control systems.

Oil & gas refineries: For pipeline automation, compressor station control.

Water and wastewater treatment plants: Monitoring flow, pressure, and chemical dosing systems.

Pharmaceutical manufacturing: For precise process control and compliance tracking.

General manufacturing: Integration with automation machinery and sensors.

Key Advantages

High Channel Density

The ANB10D supports up to 10 I/O modules in a single base, providing significant space and wiring savings.

Modular and Scalable Architecture

Easily expandable to match growing plant requirements without changing system infrastructure.

Reliable Communication via Vnet/IP

Ensures deterministic, high-speed, and redundant communication between controllers and I/O.

Strong Environmental Tolerance

Suitable for harsh industrial conditions with wide temperature and humidity tolerances.

Support for Redundant Systems

Enables high availability through dual communication paths and redundant module configuration.

Easy Installation and Maintenance

Designed for fast module replacement and minimal system downtime.

Compliance with Global Standards

Certified to meet CE, CSA, and other industrial standards, enhancing global applicability.

FAQ

Q1: What systems is the ANB10D compatible with?

A1: The ANB10D is fully compatible with Yokogawa CENTUM CS 3000 and CENTUM VP distributed control systems.

Q2: How many I/O modules can be installed on one ANB10D base unit?

A2: It supports up to 10 I/O modules on a single base.

Q3: Can I use ANB10D in high-vibration or dusty environments?

A3: Yes, its robust design and industrial-grade casing make it suitable for demanding environmental conditions.

Q4: Is hot-swapping of I/O modules supported?

A4: Yes, modules can be replaced without shutting down the system, minimizing downtime.

Q5: Does the ANB10D support redundant power supply configurations?

A5: Yes, it allows for redundant power input setups for enhanced reliability.

Q6: What type of communication protocol does it use?

A6: It uses Yokogawa’s Vnet/IP protocol for high-speed real-time control communication.

Q7: How does the ANB10D handle failures in I/O modules?

A7: The system detects faulty modules and can alert operators while maintaining system integrity.

Q8: Can the unit be mounted on both DIN rail and panels?

A8: Yes, the ANB10D supports both DIN rail and panel mount installation.

Q9: How is firmware updated on the ANB10D?

A9: Firmware updates are managed through the central system configuration tools provided by Yokogawa.

Q10: Is ANB10D suitable for use in SIL-rated systems?

A10: While it is highly reliable, users must verify compliance with specific SIL (Safety Integrity Level) requirements based on their application.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...