Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

Bently Nevada 3300/61 Dual Vector Monitor

Item Number:3300/61

Brand:Bently Nevada

Lead Time: In stock

Description:Dual Vector Monitor

Payment: T/T

Product Description

Bently Nevada 3300/61 Dual Vector Monitor is a monitoring device for large rotating machinery. This detector is not a basic vibration monitor, but a dual-channel monitor (containing two independent monitoring channels) that can simultaneously connect to two eddy current sensor probes to monitor two independent points.

Important Note: If you plan to use the 3300/61 in a system network using the SDI/DDI protocol, you must ensure that its firmware version is compatible. Otherwise, you will need to order a firmware upgrade kit.

Function & Features

- Dual SDI/DDI Communication Modes: The 3300/61 module supports both internal (with the 3300/03-02/-03 system monitor) and external (connected to SDIX/DDI/TDIX/TDXnet communication processors) communication modes.

- Vector Measurement: The 3300/61 module simultaneously monitors the vibration amplitude (e.g., peak value, RMS value) and phase; amplitude and phase together constitute a "vector" of information.

- Dynamic Data Provision: The 3300/61 can output dynamic data composed of the keyphase reference signal and the vibration signal, which can be used to generate spectrum diagrams, waveforms, etc., on analysis equipment.

Specifications

| Parameter | Details |

|---|---|

| Product Model | 3300/61 |

| Product Name | Dual Vector Monitor |

| Manufacturer | Bently Nevada |

| Channel Quantity | 2 independent monitoring channels |

| Keyphasor Input | A keyphasor signal must be connected to provide a reference for phase measurement of both channels, typically from an independent keyphasor probe. |

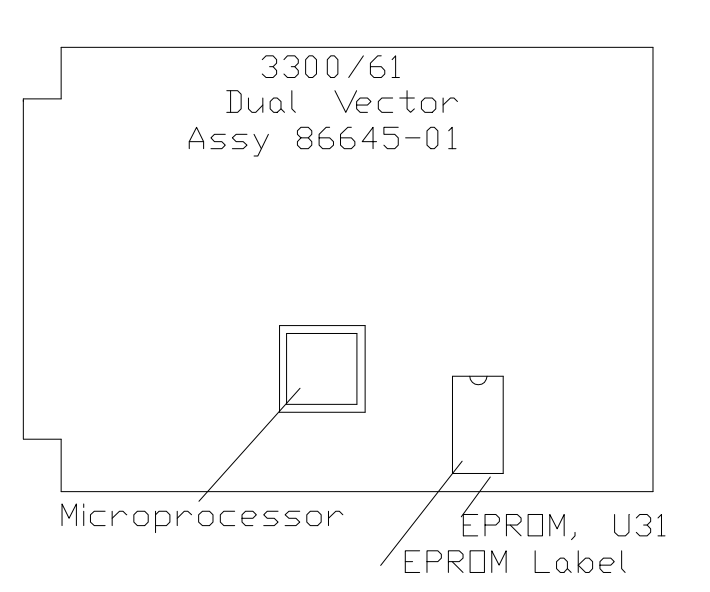

| Storage Medium | In an EPROM chip on the main circuit board (see the figurebelow.) |

FAQ

Q: What is the payment method?

A: T/T

Q: Is technical support available?

A:Yes, we have a professional technical team to address technical issues.

Q: What is the warranty?

A: 1 year

Q: What is the return and exchange policy?

A: Returns or exchanges are accepted within 7 days of receiving the goods if there are any quality issues, excluding damage caused by human error or misuse.

Q:What are the available shipping methods?

A: FedEx, DHL, UPS, and others.

Bently Nevada 3300/61 Dual Vector Monitor

Item Number:3300/61

Brand:Bently Nevada

Lead Time: In stock

Description:Dual Vector Monitor

Payment: T/T

Product Description

Bently Nevada 3300/61 Dual Vector Monitor is a monitoring device for large rotating machinery. This detector is not a basic vibration monitor, but a dual-channel monitor (containing two independent monitoring channels) that can simultaneously connect to two eddy current sensor probes to monitor two independent points.

Important Note: If you plan to use the 3300/61 in a system network using the SDI/DDI protocol, you must ensure that its firmware version is compatible. Otherwise, you will need to order a firmware upgrade kit.

Function & Features

- Dual SDI/DDI Communication Modes: The 3300/61 module supports both internal (with the 3300/03-02/-03 system monitor) and external (connected to SDIX/DDI/TDIX/TDXnet communication processors) communication modes.

- Vector Measurement: The 3300/61 module simultaneously monitors the vibration amplitude (e.g., peak value, RMS value) and phase; amplitude and phase together constitute a "vector" of information.

- Dynamic Data Provision: The 3300/61 can output dynamic data composed of the keyphase reference signal and the vibration signal, which can be used to generate spectrum diagrams, waveforms, etc., on analysis equipment.

Specifications

| Parameter | Details |

|---|---|

| Product Model | 3300/61 |

| Product Name | Dual Vector Monitor |

| Manufacturer | Bently Nevada |

| Channel Quantity | 2 independent monitoring channels |

| Keyphasor Input | A keyphasor signal must be connected to provide a reference for phase measurement of both channels, typically from an independent keyphasor probe. |

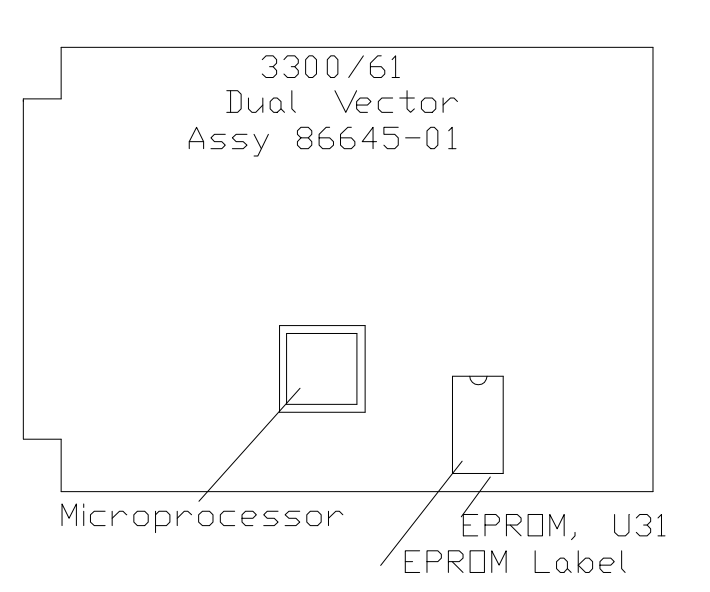

| Storage Medium | In an EPROM chip on the main circuit board (see the figurebelow.) |

FAQ

Q: What is the payment method?

A: T/T

Q: Is technical support available?

A:Yes, we have a professional technical team to address technical issues.

Q: What is the warranty?

A: 1 year

Q: What is the return and exchange policy?

A: Returns or exchanges are accepted within 7 days of receiving the goods if there are any quality issues, excluding damage caused by human error or misuse.

Q:What are the available shipping methods?

A: FedEx, DHL, UPS, and others.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...