Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

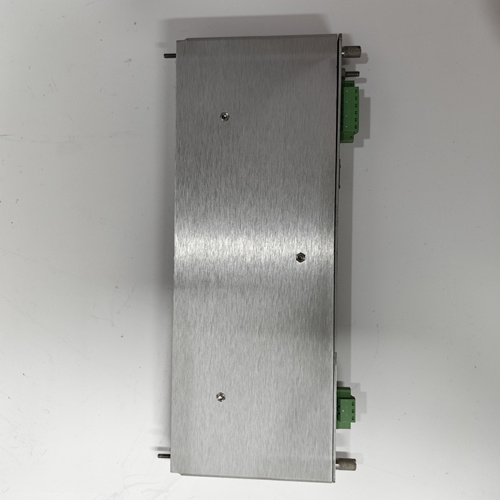

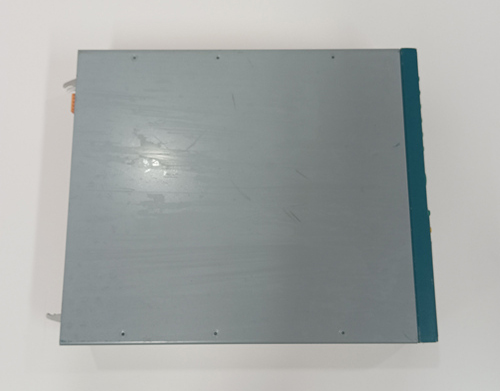

Bently Nevada 1900/65A-00-01-01-01-01 Universal Device Monitor

Manufacturer:Bently Nevada

Product Number:1900/65A-00-01-01-01-01

Product Type:Universal Device Monitor

Origin:USA

Dimensions:196.9 x 149.4 x 74.4mm

Weight:0.77 kg

Views:61

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 1900/65A-00-01-01-01-01 Universal Device Monitor is a highly reliable, flexible, and easy-to-integrate monitoring solution designed for real-time condition monitoring of industrial machinery. Built for use in a wide range of industries, it provides actionable data that helps prevent unscheduled downtime and facilitates predictive maintenance strategies. By monitoring key parameters such as vibration, temperature, and pressure, it enhances overall machine performance, reducing wear and tear on equipment and increasing the efficiency of operations.

The device is specifically designed to integrate seamlessly with existing systems while offering advanced communication capabilities, making it ideal for industrial automation and process control systems. Its durable construction allows it to function reliably in harsh environments, ensuring that critical machinery is constantly monitored without interruption.

Product Specifications

| Parameter | Details |

|---|---|

| Model | 1900/65A-00-01-01-01-01 |

| Dimensions (L x W x H) | 196.9 x 149.4 x 74.4 mm |

| Weight | 0.77 kg |

| Input Voltage | 24 VDC |

| Power Consumption | 2.5 W |

| Temperature Range | -20°C to +60°C |

| Humidity Range | 5% to 95% (non-condensing) |

| Communication Protocol | Modbus, Ethernet, TCP/IP, Serial RS-232/485 |

| Mounting Type | Wall mount or DIN rail |

| Approvals | CE, UL, ATEX (optional) |

Product Applications

The Bently Nevada 1900/65A-00-01-01-01-01 Universal Device Monitor is ideal for a broad range of industrial and manufacturing applications where equipment uptime is critical. Key applications include:

Rotating Machinery Monitoring: The device is essential for monitoring motors, turbines, compressors, pumps, and other rotating equipment.

Predictive Maintenance: By capturing real-time data, it detects potential failures early, allowing operators to take preventative action before breakdowns occur.

Process Monitoring: In industries such as oil and gas, power generation, and manufacturing, it helps ensure optimal equipment operation, minimizing the risk of failure in critical systems.

Condition Monitoring: Provides continuous feedback on parameters such as vibration, temperature, and pressure, ensuring machinery operates within optimal conditions.

Energy Efficiency: The monitor helps track energy consumption and operational efficiency, enabling businesses to optimize energy usage across various equipment.

Product Advantages

Real-Time Monitoring: The device offers continuous, real-time data acquisition, enabling operators to make timely and informed decisions that can prevent downtime.

Durability and Longevity: Built to withstand tough industrial conditions, the 1900/65A-00-01-01-01-01 model is reliable even in extreme environments such as high temperatures and humidity.

Modular Design: With a flexible design, the monitor can be easily adapted to different system configurations and integrated with other industrial systems.

Multiple Communication Options: Supports various communication protocols like Modbus, Ethernet, TCP/IP, and Serial, making it highly compatible with different control systems.

Advanced Diagnostics: The device can perform in-depth diagnostics, identifying issues such as mechanical imbalances, temperature spikes, and other anomalies in machinery.

Scalability: Suitable for both small applications and large-scale industrial operations, allowing for easy expansion as monitoring needs grow.

Improved Safety: By identifying problems early, the monitor reduces the likelihood of dangerous equipment failures, contributing to overall workplace safety.

Frequently Asked Questions (FAQ)

What is the power consumption of the 1900/65A-00-01-01-01-01 device?

The device consumes 2.5 watts of power during operation.

Can the device be used in hazardous environments?

Yes, the device is certified with optional ATEX certification, which makes it suitable for hazardous locations.

What is the operating temperature range of the device?

The operating temperature range is from -20°C to +60°C, making it adaptable to various industrial environments.

Can the device monitor multiple pieces of equipment at once?

Yes, the monitor can be integrated with a larger system to monitor multiple devices simultaneously, providing centralized control.

What communication protocols are supported by this model?

It supports Modbus, Ethernet, TCP/IP, and Serial RS-232/485 communication protocols.

What mounting options are available for this device?

The 1900/65A-00-01-01-01-01 can be mounted on a wall or attached to a DIN rail for flexible installation.

What is the weight of the device?

The device weighs 0.77 kg, making it lightweight and easy to handle.

Does this device offer real-time diagnostics?

Yes, the 1900/65A-00-01-01-01-01 is equipped with real-time diagnostic capabilities to identify machinery health issues early.

Is the device compatible with third-party monitoring systems?

Yes, the device supports multiple communication protocols, ensuring seamless integration with third-party control systems.

How can this device improve energy efficiency?

By continuously monitoring key equipment parameters, the device helps optimize the operation of machinery, leading to more efficient energy usage.

Bently Nevada 1900/65A-00-01-01-01-01 Universal Device Monitor

Manufacturer:Bently Nevada

Product Number:1900/65A-00-01-01-01-01

Product Type:Universal Device Monitor

Origin:USA

Dimensions:196.9 x 149.4 x 74.4mm

Weight:0.77 kg

Views:61

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 1900/65A-00-01-01-01-01 Universal Device Monitor is a highly reliable, flexible, and easy-to-integrate monitoring solution designed for real-time condition monitoring of industrial machinery. Built for use in a wide range of industries, it provides actionable data that helps prevent unscheduled downtime and facilitates predictive maintenance strategies. By monitoring key parameters such as vibration, temperature, and pressure, it enhances overall machine performance, reducing wear and tear on equipment and increasing the efficiency of operations.

The device is specifically designed to integrate seamlessly with existing systems while offering advanced communication capabilities, making it ideal for industrial automation and process control systems. Its durable construction allows it to function reliably in harsh environments, ensuring that critical machinery is constantly monitored without interruption.

Product Specifications

| Parameter | Details |

|---|---|

| Model | 1900/65A-00-01-01-01-01 |

| Dimensions (L x W x H) | 196.9 x 149.4 x 74.4 mm |

| Weight | 0.77 kg |

| Input Voltage | 24 VDC |

| Power Consumption | 2.5 W |

| Temperature Range | -20°C to +60°C |

| Humidity Range | 5% to 95% (non-condensing) |

| Communication Protocol | Modbus, Ethernet, TCP/IP, Serial RS-232/485 |

| Mounting Type | Wall mount or DIN rail |

| Approvals | CE, UL, ATEX (optional) |

Product Applications

The Bently Nevada 1900/65A-00-01-01-01-01 Universal Device Monitor is ideal for a broad range of industrial and manufacturing applications where equipment uptime is critical. Key applications include:

Rotating Machinery Monitoring: The device is essential for monitoring motors, turbines, compressors, pumps, and other rotating equipment.

Predictive Maintenance: By capturing real-time data, it detects potential failures early, allowing operators to take preventative action before breakdowns occur.

Process Monitoring: In industries such as oil and gas, power generation, and manufacturing, it helps ensure optimal equipment operation, minimizing the risk of failure in critical systems.

Condition Monitoring: Provides continuous feedback on parameters such as vibration, temperature, and pressure, ensuring machinery operates within optimal conditions.

Energy Efficiency: The monitor helps track energy consumption and operational efficiency, enabling businesses to optimize energy usage across various equipment.

Product Advantages

Real-Time Monitoring: The device offers continuous, real-time data acquisition, enabling operators to make timely and informed decisions that can prevent downtime.

Durability and Longevity: Built to withstand tough industrial conditions, the 1900/65A-00-01-01-01-01 model is reliable even in extreme environments such as high temperatures and humidity.

Modular Design: With a flexible design, the monitor can be easily adapted to different system configurations and integrated with other industrial systems.

Multiple Communication Options: Supports various communication protocols like Modbus, Ethernet, TCP/IP, and Serial, making it highly compatible with different control systems.

Advanced Diagnostics: The device can perform in-depth diagnostics, identifying issues such as mechanical imbalances, temperature spikes, and other anomalies in machinery.

Scalability: Suitable for both small applications and large-scale industrial operations, allowing for easy expansion as monitoring needs grow.

Improved Safety: By identifying problems early, the monitor reduces the likelihood of dangerous equipment failures, contributing to overall workplace safety.

Frequently Asked Questions (FAQ)

What is the power consumption of the 1900/65A-00-01-01-01-01 device?

The device consumes 2.5 watts of power during operation.

Can the device be used in hazardous environments?

Yes, the device is certified with optional ATEX certification, which makes it suitable for hazardous locations.

What is the operating temperature range of the device?

The operating temperature range is from -20°C to +60°C, making it adaptable to various industrial environments.

Can the device monitor multiple pieces of equipment at once?

Yes, the monitor can be integrated with a larger system to monitor multiple devices simultaneously, providing centralized control.

What communication protocols are supported by this model?

It supports Modbus, Ethernet, TCP/IP, and Serial RS-232/485 communication protocols.

What mounting options are available for this device?

The 1900/65A-00-01-01-01-01 can be mounted on a wall or attached to a DIN rail for flexible installation.

What is the weight of the device?

The device weighs 0.77 kg, making it lightweight and easy to handle.

Does this device offer real-time diagnostics?

Yes, the 1900/65A-00-01-01-01-01 is equipped with real-time diagnostic capabilities to identify machinery health issues early.

Is the device compatible with third-party monitoring systems?

Yes, the device supports multiple communication protocols, ensuring seamless integration with third-party control systems.

How can this device improve energy efficiency?

By continuously monitoring key equipment parameters, the device helps optimize the operation of machinery, leading to more efficient energy usage.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...