Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

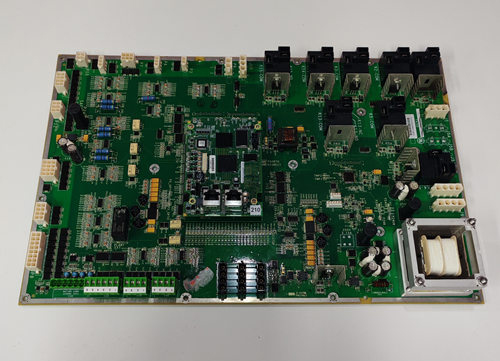

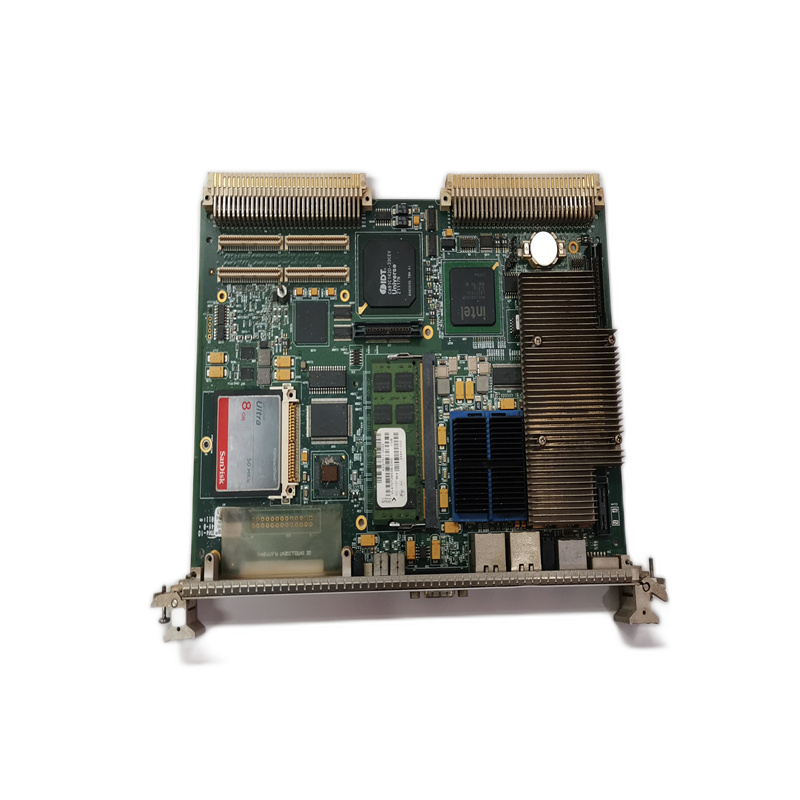

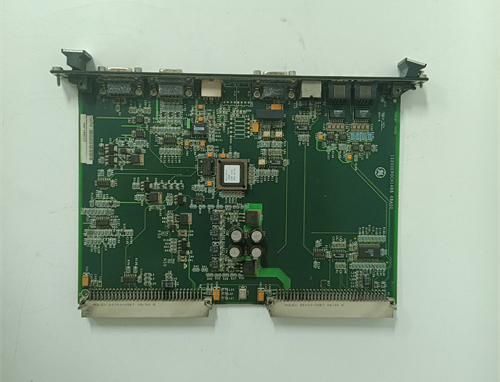

General Electric IC693UDR001 Programmable controller

Manufacturer:GE

Product Number:IC693UDR001

Condition:Programmable controller

Origin:USA

Dimensions:150 x 130 x 40 mm

Weight:0.5 kg

Views:41

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

GE IC693UDR001 is a Micro PLC module from the GE Fanuc Series 90-30 family. Designed to offer compact control capabilities, this unit integrates a CPU, I/O, and power supply in one module. The IC693UDR001 is widely adopted in small to mid-size industrial automation systems where space efficiency, cost-effectiveness, and reliable processing are key requirements. It is ideally suited for standalone applications or as a remote module in larger control networks.

Product Specifications

| Parameter | Description |

|---|---|

| Product Model | GE IC693UDR001 |

| Product Type | Micro PLC / CPU Module |

| Manufacturer | GE Fanuc (General Electric) |

| Series | Series 90-30 |

| Integrated I/O | 14 DC Inputs, 10 Relay Outputs |

| Programming Software | Proficy Machine Edition / Logic Developer |

| Communication Port | One built-in RS-232 serial port |

| Power Supply | Built-in power supply (120/240 VAC input) |

| Memory Capacity | 6K words user memory |

| Mounting Type | DIN-rail or panel-mounted |

| Operating Temperature | 0°C to 60°C |

| Storage Temperature | -40°C to 85°C |

| Dimensions (H x W x D) | 150 x 130 x 40 mm |

| Weight | 0.5 kg |

| Certifications | UL, CSA, CE |

Product Applications

Packaging machinery: Provides precise and compact control in automated packaging systems.

Material handling: Controls conveyors and automated lifting mechanisms in warehouses and factories.

Food & Beverage: Used in mixers, dispensers, and bottling lines for its reliability.

Water treatment systems: Ideal for monitoring and controlling small-scale pumping and treatment processes.

Building automation: Manages HVAC, lighting, and energy systems.

Textile and printing machinery: Delivers high-speed logic processing for machine operations.

Product Advantages

All-in-One Design: Integrates CPU, I/O, and power in a single compact module, minimizing wiring and space.

Reliable Performance: Built for long-term industrial usage with high MTBF.

Ease of Installation: Panel or DIN rail mountable with standard connectors.

Wide Software Compatibility: Supports GE’s Proficy Logic Developer for simple programming.

Scalable Architecture: Works as a standalone unit or part of a larger Series 90-30 system.

Industrial Hardened: Built to perform in harsh operating conditions with wide temperature and voltage tolerances.

Frequently Asked Questions (FAQ)

Q1: What kind of I/O does the IC693UDR001 offer?

A1: It includes 14 DC inputs and 10 relay outputs, suitable for general-purpose digital control.

Q2: Can this PLC be programmed using Proficy Machine Edition?

A2: Yes, the IC693UDR001 is fully compatible with GE’s Proficy Machine Edition software.

Q3: Does it include an integrated power supply?

A3: Yes, it features a built-in power supply that accepts 120/240 VAC input.

Q4: What is the physical size of the unit?

A4: The dimensions are 150 x 130 x 40 mm.

Q5: Is this model suitable for remote I/O applications?

A5: It can be used as a remote node when networked with a host PLC system.

Q6: Can this module communicate over Ethernet?

A6: Not directly. It supports serial RS-232. Ethernet requires an additional communication module.

Q7: What is the maximum ambient temperature for operation?

A7: It is rated for continuous operation up to 60°C.

Q8: What industries commonly use this model?

A8: It is widely used in packaging, water treatment, and small industrial automation.

Q9: How is this unit mounted?

A9: It can be mounted via DIN rail or directly on a panel.

Q10: Does the unit support expansion modules?

A10: Yes, it supports Series 90-30 expansion I/O and specialty modules.

General Electric IC693UDR001 Programmable controller

Manufacturer:GE

Product Number:IC693UDR001

Condition:Programmable controller

Origin:USA

Dimensions:150 x 130 x 40 mm

Weight:0.5 kg

Views:41

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

GE IC693UDR001 is a Micro PLC module from the GE Fanuc Series 90-30 family. Designed to offer compact control capabilities, this unit integrates a CPU, I/O, and power supply in one module. The IC693UDR001 is widely adopted in small to mid-size industrial automation systems where space efficiency, cost-effectiveness, and reliable processing are key requirements. It is ideally suited for standalone applications or as a remote module in larger control networks.

Product Specifications

| Parameter | Description |

|---|---|

| Product Model | GE IC693UDR001 |

| Product Type | Micro PLC / CPU Module |

| Manufacturer | GE Fanuc (General Electric) |

| Series | Series 90-30 |

| Integrated I/O | 14 DC Inputs, 10 Relay Outputs |

| Programming Software | Proficy Machine Edition / Logic Developer |

| Communication Port | One built-in RS-232 serial port |

| Power Supply | Built-in power supply (120/240 VAC input) |

| Memory Capacity | 6K words user memory |

| Mounting Type | DIN-rail or panel-mounted |

| Operating Temperature | 0°C to 60°C |

| Storage Temperature | -40°C to 85°C |

| Dimensions (H x W x D) | 150 x 130 x 40 mm |

| Weight | 0.5 kg |

| Certifications | UL, CSA, CE |

Product Applications

Packaging machinery: Provides precise and compact control in automated packaging systems.

Material handling: Controls conveyors and automated lifting mechanisms in warehouses and factories.

Food & Beverage: Used in mixers, dispensers, and bottling lines for its reliability.

Water treatment systems: Ideal for monitoring and controlling small-scale pumping and treatment processes.

Building automation: Manages HVAC, lighting, and energy systems.

Textile and printing machinery: Delivers high-speed logic processing for machine operations.

Product Advantages

All-in-One Design: Integrates CPU, I/O, and power in a single compact module, minimizing wiring and space.

Reliable Performance: Built for long-term industrial usage with high MTBF.

Ease of Installation: Panel or DIN rail mountable with standard connectors.

Wide Software Compatibility: Supports GE’s Proficy Logic Developer for simple programming.

Scalable Architecture: Works as a standalone unit or part of a larger Series 90-30 system.

Industrial Hardened: Built to perform in harsh operating conditions with wide temperature and voltage tolerances.

Frequently Asked Questions (FAQ)

Q1: What kind of I/O does the IC693UDR001 offer?

A1: It includes 14 DC inputs and 10 relay outputs, suitable for general-purpose digital control.

Q2: Can this PLC be programmed using Proficy Machine Edition?

A2: Yes, the IC693UDR001 is fully compatible with GE’s Proficy Machine Edition software.

Q3: Does it include an integrated power supply?

A3: Yes, it features a built-in power supply that accepts 120/240 VAC input.

Q4: What is the physical size of the unit?

A4: The dimensions are 150 x 130 x 40 mm.

Q5: Is this model suitable for remote I/O applications?

A5: It can be used as a remote node when networked with a host PLC system.

Q6: Can this module communicate over Ethernet?

A6: Not directly. It supports serial RS-232. Ethernet requires an additional communication module.

Q7: What is the maximum ambient temperature for operation?

A7: It is rated for continuous operation up to 60°C.

Q8: What industries commonly use this model?

A8: It is widely used in packaging, water treatment, and small industrial automation.

Q9: How is this unit mounted?

A9: It can be mounted via DIN rail or directly on a panel.

Q10: Does the unit support expansion modules?

A10: Yes, it supports Series 90-30 expansion I/O and specialty modules.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...