Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

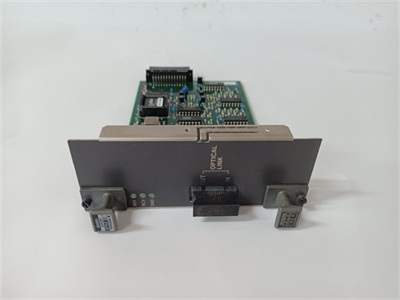

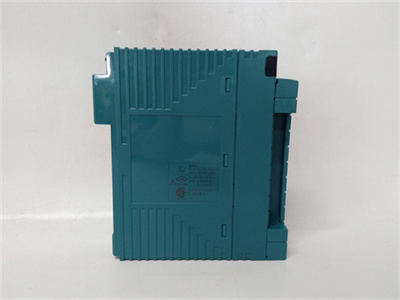

Yokogawa VI451-10 Communication Module

Manufacturer:Yokogawa

Product Number: VI451-10

Product Type:Communication Module

Origin:Japan

Dimensions:266 x 210 x 55mm

Weight:2.5kg

Views:60

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

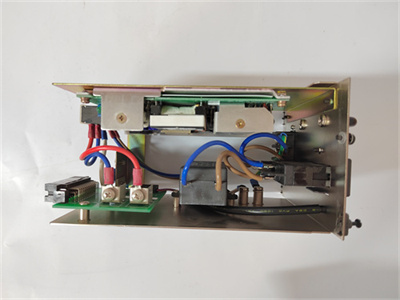

The Yokogawa VI451-10 is a high-performance communication module designed to integrate seamlessly into Yokogawa’s CENTUM VP and other DCS systems. It functions as a critical interface between field devices and control units, ensuring fast, reliable, and secure data exchange within complex industrial environments. This module supports various communication protocols, enabling interoperability with diverse hardware platforms and enhancing system scalability and flexibility.

The VI451-10 is engineered with industrial-grade components that offer enhanced durability, consistent performance, and robust communication capability, even in harsh operating conditions. This module ensures precise signal transmission, minimizes data loss, and enables fault-tolerant control networks. As part of the renowned Yokogawa control platform, the VI451-10 exemplifies precision engineering, high-quality craftsmanship, and decades of process automation expertise.

Product Parameters

| Parameter | Specification |

|---|---|

| Model Number | VI451-10 |

| Manufacturer | Yokogawa Electric Corporation |

| Function | Communication Interface Module |

| Supported Protocols | Vnet/IP, FOUNDATION Fieldbus, HART |

| Interface Type | Optical Ethernet / Dual Redundant Bus |

| Data Transmission Rate | 100 Mbps (typical) |

| Operating Voltage | 24V DC (typical) |

| Power Consumption | Approx. 6W |

| Dimensions (L x W x H) | 266mm x 210mm x 55mm |

| Weight | 2.5 kg |

| Mounting Method | Mounted in standard I/O node rack |

| Operating Temperature | 0°C to 55°C |

| Storage Temperature | -20°C to +70°C |

| Humidity Range | 5% to 95% RH (non-condensing) |

| Isolation Type | Optical Isolation |

| Redundancy Support | Yes, dual-channel redundancy supported |

| MTBF (Mean Time Between Failures) | Over 200,000 hours |

Product Applications

The VI451-10 is widely deployed in industries where real-time, high-integrity communication is essential. It plays a critical role in distributed control systems by providing robust and efficient communication between control processors and I/O devices.

Oil & Gas Industry: Ensures safe data transmission between field sensors and control stations in refineries and offshore platforms.

Chemical Plants: Facilitates real-time monitoring and control across batch processing units and reactors.

Power Generation: Supports communication in turbine control systems and auxiliary process units.

Water Treatment Plants: Enables reliable and stable communication in SCADA systems for municipal and industrial water facilities.

Pharmaceutical Manufacturing: Assures precise data handling in compliance with GMP and FDA standards.

Pulp & Paper Industry: Maintains seamless data exchange in continuous process control systems.

Product Advantages

High Reliability: Built with industrial-grade components, ensuring uninterrupted communication and fault resilience.

Redundant Communication: Dual-bus architecture provides automatic switchover in case of failure, increasing system uptime.

Versatile Protocol Support: Compatible with modern and legacy protocols including Vnet/IP, allowing flexible integration.

Compact Design: Despite advanced capabilities, it fits compactly within standard I/O node racks, saving cabinet space.

Excellent EMC Performance: Designed to resist electromagnetic interference, ensuring stable performance in noisy environments.

Long Lifecycle Support: Yokogawa offers extended support and lifecycle management, reducing long-term maintenance costs.

Real-Time Diagnostics: Integrated LED indicators and diagnostics simplify troubleshooting and predictive maintenance.

Seamless Integration: Designed to work optimally with Yokogawa control systems, ensuring plug-and-play configuration.

Optimized Bandwidth Usage: Efficient data transfer management reduces communication bottlenecks in large-scale systems.

User-Friendly Configuration: Supports intuitive configuration tools within the Yokogawa system architecture.

Frequently Asked Questions (FAQ)

What is the primary function of the VI451-10 module?

It acts as a communication interface between field devices and the controller in a distributed control system (DCS).

Is the VI451-10 compatible with non-Yokogawa systems?

It is optimized for Yokogawa platforms but can communicate with other systems supporting compatible protocols.

Does the VI451-10 support redundancy?

Yes, it supports dual communication redundancy for high availability.

What type of communication protocols does it support?

It supports Vnet/IP, FOUNDATION Fieldbus, and HART protocols.

How is the VI451-10 mounted?

It is mounted within a standard I/O node rack inside a control cabinet.

What is the recommended operating temperature range?

The module is designed to operate reliably between 0°C to 55°C.

Is the module suitable for use in hazardous areas?

It must be installed within certified enclosures if used in hazardous areas, depending on regional standards.

Can the module be hot-swapped?

No, power must be disconnected before replacing the module to ensure safety.

Does the module support firmware updates?

Yes, firmware can be upgraded via the Yokogawa system engineering tools.

How long is the average service life of the VI451-10?

With regular maintenance, the module typically lasts over 10 years under standard operating conditions.

Yokogawa VI451-10 Communication Module

Manufacturer:Yokogawa

Product Number: VI451-10

Product Type:Communication Module

Origin:Japan

Dimensions:266 x 210 x 55mm

Weight:2.5kg

Views:60

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa VI451-10 is a high-performance communication module designed to integrate seamlessly into Yokogawa’s CENTUM VP and other DCS systems. It functions as a critical interface between field devices and control units, ensuring fast, reliable, and secure data exchange within complex industrial environments. This module supports various communication protocols, enabling interoperability with diverse hardware platforms and enhancing system scalability and flexibility.

The VI451-10 is engineered with industrial-grade components that offer enhanced durability, consistent performance, and robust communication capability, even in harsh operating conditions. This module ensures precise signal transmission, minimizes data loss, and enables fault-tolerant control networks. As part of the renowned Yokogawa control platform, the VI451-10 exemplifies precision engineering, high-quality craftsmanship, and decades of process automation expertise.

Product Parameters

| Parameter | Specification |

|---|---|

| Model Number | VI451-10 |

| Manufacturer | Yokogawa Electric Corporation |

| Function | Communication Interface Module |

| Supported Protocols | Vnet/IP, FOUNDATION Fieldbus, HART |

| Interface Type | Optical Ethernet / Dual Redundant Bus |

| Data Transmission Rate | 100 Mbps (typical) |

| Operating Voltage | 24V DC (typical) |

| Power Consumption | Approx. 6W |

| Dimensions (L x W x H) | 266mm x 210mm x 55mm |

| Weight | 2.5 kg |

| Mounting Method | Mounted in standard I/O node rack |

| Operating Temperature | 0°C to 55°C |

| Storage Temperature | -20°C to +70°C |

| Humidity Range | 5% to 95% RH (non-condensing) |

| Isolation Type | Optical Isolation |

| Redundancy Support | Yes, dual-channel redundancy supported |

| MTBF (Mean Time Between Failures) | Over 200,000 hours |

Product Applications

The VI451-10 is widely deployed in industries where real-time, high-integrity communication is essential. It plays a critical role in distributed control systems by providing robust and efficient communication between control processors and I/O devices.

Oil & Gas Industry: Ensures safe data transmission between field sensors and control stations in refineries and offshore platforms.

Chemical Plants: Facilitates real-time monitoring and control across batch processing units and reactors.

Power Generation: Supports communication in turbine control systems and auxiliary process units.

Water Treatment Plants: Enables reliable and stable communication in SCADA systems for municipal and industrial water facilities.

Pharmaceutical Manufacturing: Assures precise data handling in compliance with GMP and FDA standards.

Pulp & Paper Industry: Maintains seamless data exchange in continuous process control systems.

Product Advantages

High Reliability: Built with industrial-grade components, ensuring uninterrupted communication and fault resilience.

Redundant Communication: Dual-bus architecture provides automatic switchover in case of failure, increasing system uptime.

Versatile Protocol Support: Compatible with modern and legacy protocols including Vnet/IP, allowing flexible integration.

Compact Design: Despite advanced capabilities, it fits compactly within standard I/O node racks, saving cabinet space.

Excellent EMC Performance: Designed to resist electromagnetic interference, ensuring stable performance in noisy environments.

Long Lifecycle Support: Yokogawa offers extended support and lifecycle management, reducing long-term maintenance costs.

Real-Time Diagnostics: Integrated LED indicators and diagnostics simplify troubleshooting and predictive maintenance.

Seamless Integration: Designed to work optimally with Yokogawa control systems, ensuring plug-and-play configuration.

Optimized Bandwidth Usage: Efficient data transfer management reduces communication bottlenecks in large-scale systems.

User-Friendly Configuration: Supports intuitive configuration tools within the Yokogawa system architecture.

Frequently Asked Questions (FAQ)

What is the primary function of the VI451-10 module?

It acts as a communication interface between field devices and the controller in a distributed control system (DCS).

Is the VI451-10 compatible with non-Yokogawa systems?

It is optimized for Yokogawa platforms but can communicate with other systems supporting compatible protocols.

Does the VI451-10 support redundancy?

Yes, it supports dual communication redundancy for high availability.

What type of communication protocols does it support?

It supports Vnet/IP, FOUNDATION Fieldbus, and HART protocols.

How is the VI451-10 mounted?

It is mounted within a standard I/O node rack inside a control cabinet.

What is the recommended operating temperature range?

The module is designed to operate reliably between 0°C to 55°C.

Is the module suitable for use in hazardous areas?

It must be installed within certified enclosures if used in hazardous areas, depending on regional standards.

Can the module be hot-swapped?

No, power must be disconnected before replacing the module to ensure safety.

Does the module support firmware updates?

Yes, firmware can be upgraded via the Yokogawa system engineering tools.

How long is the average service life of the VI451-10?

With regular maintenance, the module typically lasts over 10 years under standard operating conditions.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...