Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

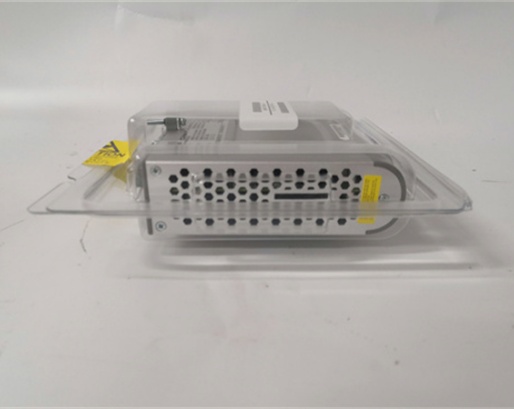

Honeywell MU-PAOY22 80363969-100 Analog Output Processor Board

Manufacturer:Honeywell

Product Number:MU-PAOY22 80363969-100

Product Type:Analog Output Processor Board

Origin:USA

Dimensions:40 × 260 × 220 mm

Weight:1.4 kg

Views:32

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell MU-PAOY22 80363969-100 is a high-performance Analog Output Processor Board engineered to handle critical analog signal processing tasks in Honeywell’s Experion PKS and TDC 3000 control systems. Designed for robust industrial environments, this board delivers precision analog output control to a wide variety of field devices such as control valves, actuators, and transmitters.

The MU-PAOY22 serves as a crucial interface between the controller and final control elements, managing the conversion of digital commands into stable analog output signals. It is ideal for applications where high availability, fault tolerance, and precision output are essential. Its compact and modular design allows for seamless integration and efficient maintenance within a Honeywell I/O framework.

Product Specifications

| Parameter | Description |

|---|---|

| Model | MU-PAOY22 |

| Part Number | 80363969-100 |

| Module Type | Analog Output Processor Board |

| Function | Converts digital signals to analog outputs |

| Number of Output Channels | 8 or 16 channels (depending on system configuration) |

| Signal Type | 4–20 mA current loop |

| Output Resolution | 16-bit DAC |

| Output Accuracy | ±0.05% of full scale |

| Redundancy Support | Yes, dual-processor or dual-path redundancy |

| Switchover Time (Redundant) | <10 ms |

| Diagnostics | Built-in diagnostics with status indicators |

| Signal Isolation | Yes, galvanic isolation from system and other channels |

| Communication | Backplane I/O bus |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5% to 95% non-condensing |

| Power Supply | Supplied via system backplane |

| Mounting Type | Rack-mounted in I/O chassis |

| Dimensions (W × H × D) | 40 × 260 × 220 mm |

| Weight | 1.4 kg |

| Certifications | CE, UL, CSA, FM |

| System Compatibility | Honeywell Experion PKS, TDC 3000 |

| Hot Swappable | Yes |

Product Applications

The MU-PAOY22 Analog Output Processor Board is engineered for use in a variety of critical control system applications, particularly where analog output accuracy and continuity are non-negotiable. Common industrial use cases include:

Oil & Gas Refining: Controls fuel flow, pressure relief valves, and process dampers.

Chemical Processing: Regulates dosing pumps, proportional valves, and mixers with high precision.

Power Generation: Sends analog signals to steam control valves, feedwater systems, and actuator drives.

Pharmaceutical Industry: Ensures highly accurate control in temperature-sensitive and flow-regulated processes.

Food & Beverage: Maintains consistent ingredient flow and environmental conditions during processing.

Water & Wastewater Treatment: Controls chemical injectors, pump speed controllers, and flow regulators.

Product Advantages

High Output Accuracy: Offers a 16-bit digital-to-analog conversion with ±0.05% accuracy for precision control.

Redundant Design: Supports redundancy at the board and system level to ensure zero-loss output continuity.

Galvanic Isolation: Provides strong protection against ground loops and electrical interference.

Built-in Diagnostics: Continuously monitors signal integrity and health, simplifying maintenance and troubleshooting.

Fast Response Time: Enables real-time analog output adjustments critical in dynamic process environments.

Hot-Swappable Capability: Allows for in-operation replacement or upgrade without system shutdown.

Seamless Integration: Fully compatible with Honeywell control systems and standardized backplane architecture.

Field-Proven Reliability: Extensively used in hazardous and mission-critical applications worldwide.

Frequently Asked Questions (FAQ)

What types of analog signals does the MU-PAOY22 output?

It outputs 4–20 mA current loop signals, compatible with most industrial actuators and control devices.

Does the board support redundancy?

Yes, it supports redundant configurations including dual processor paths and switchover within 10 ms.

Can this board be hot-swapped without stopping the process?

Yes, it supports hot-swapping for ease of maintenance and minimal downtime.

What is the output resolution of the processor board?

The module uses a 16-bit DAC to provide highly accurate output resolution.

Is there channel-to-channel electrical isolation?

While it offers full isolation from the system and ground, isolation between channels depends on the chassis design.

How are diagnostics communicated to the control system?

Via status LEDs and internal health check reports sent through the backplane bus to the control processor.

Can the MU-PAOY22 be used in safety-critical applications?

Yes, when configured properly, it is suitable for use in SIL-rated systems requiring reliable analog output.

How does the module handle signal degradation or failure?

It uses internal diagnostics to detect faults and automatically switch to a redundant path if configured.

What happens to output signals during a system restart?

The processor board retains its last known state or defaults to a safe state as configured by the control logic.

How many output channels can be configured simultaneously?

It can support either 8 or 16 analog output channels depending on system settings and installation.

Honeywell MU-PAOY22 80363969-100 Analog Output Processor Board

Manufacturer:Honeywell

Product Number:MU-PAOY22 80363969-100

Product Type:Analog Output Processor Board

Origin:USA

Dimensions:40 × 260 × 220 mm

Weight:1.4 kg

Views:32

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell MU-PAOY22 80363969-100 is a high-performance Analog Output Processor Board engineered to handle critical analog signal processing tasks in Honeywell’s Experion PKS and TDC 3000 control systems. Designed for robust industrial environments, this board delivers precision analog output control to a wide variety of field devices such as control valves, actuators, and transmitters.

The MU-PAOY22 serves as a crucial interface between the controller and final control elements, managing the conversion of digital commands into stable analog output signals. It is ideal for applications where high availability, fault tolerance, and precision output are essential. Its compact and modular design allows for seamless integration and efficient maintenance within a Honeywell I/O framework.

Product Specifications

| Parameter | Description |

|---|---|

| Model | MU-PAOY22 |

| Part Number | 80363969-100 |

| Module Type | Analog Output Processor Board |

| Function | Converts digital signals to analog outputs |

| Number of Output Channels | 8 or 16 channels (depending on system configuration) |

| Signal Type | 4–20 mA current loop |

| Output Resolution | 16-bit DAC |

| Output Accuracy | ±0.05% of full scale |

| Redundancy Support | Yes, dual-processor or dual-path redundancy |

| Switchover Time (Redundant) | <10 ms |

| Diagnostics | Built-in diagnostics with status indicators |

| Signal Isolation | Yes, galvanic isolation from system and other channels |

| Communication | Backplane I/O bus |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5% to 95% non-condensing |

| Power Supply | Supplied via system backplane |

| Mounting Type | Rack-mounted in I/O chassis |

| Dimensions (W × H × D) | 40 × 260 × 220 mm |

| Weight | 1.4 kg |

| Certifications | CE, UL, CSA, FM |

| System Compatibility | Honeywell Experion PKS, TDC 3000 |

| Hot Swappable | Yes |

Product Applications

The MU-PAOY22 Analog Output Processor Board is engineered for use in a variety of critical control system applications, particularly where analog output accuracy and continuity are non-negotiable. Common industrial use cases include:

Oil & Gas Refining: Controls fuel flow, pressure relief valves, and process dampers.

Chemical Processing: Regulates dosing pumps, proportional valves, and mixers with high precision.

Power Generation: Sends analog signals to steam control valves, feedwater systems, and actuator drives.

Pharmaceutical Industry: Ensures highly accurate control in temperature-sensitive and flow-regulated processes.

Food & Beverage: Maintains consistent ingredient flow and environmental conditions during processing.

Water & Wastewater Treatment: Controls chemical injectors, pump speed controllers, and flow regulators.

Product Advantages

High Output Accuracy: Offers a 16-bit digital-to-analog conversion with ±0.05% accuracy for precision control.

Redundant Design: Supports redundancy at the board and system level to ensure zero-loss output continuity.

Galvanic Isolation: Provides strong protection against ground loops and electrical interference.

Built-in Diagnostics: Continuously monitors signal integrity and health, simplifying maintenance and troubleshooting.

Fast Response Time: Enables real-time analog output adjustments critical in dynamic process environments.

Hot-Swappable Capability: Allows for in-operation replacement or upgrade without system shutdown.

Seamless Integration: Fully compatible with Honeywell control systems and standardized backplane architecture.

Field-Proven Reliability: Extensively used in hazardous and mission-critical applications worldwide.

Frequently Asked Questions (FAQ)

What types of analog signals does the MU-PAOY22 output?

It outputs 4–20 mA current loop signals, compatible with most industrial actuators and control devices.

Does the board support redundancy?

Yes, it supports redundant configurations including dual processor paths and switchover within 10 ms.

Can this board be hot-swapped without stopping the process?

Yes, it supports hot-swapping for ease of maintenance and minimal downtime.

What is the output resolution of the processor board?

The module uses a 16-bit DAC to provide highly accurate output resolution.

Is there channel-to-channel electrical isolation?

While it offers full isolation from the system and ground, isolation between channels depends on the chassis design.

How are diagnostics communicated to the control system?

Via status LEDs and internal health check reports sent through the backplane bus to the control processor.

Can the MU-PAOY22 be used in safety-critical applications?

Yes, when configured properly, it is suitable for use in SIL-rated systems requiring reliable analog output.

How does the module handle signal degradation or failure?

It uses internal diagnostics to detect faults and automatically switch to a redundant path if configured.

What happens to output signals during a system restart?

The processor board retains its last known state or defaults to a safe state as configured by the control logic.

How many output channels can be configured simultaneously?

It can support either 8 or 16 analog output channels depending on system settings and installation.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...