Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

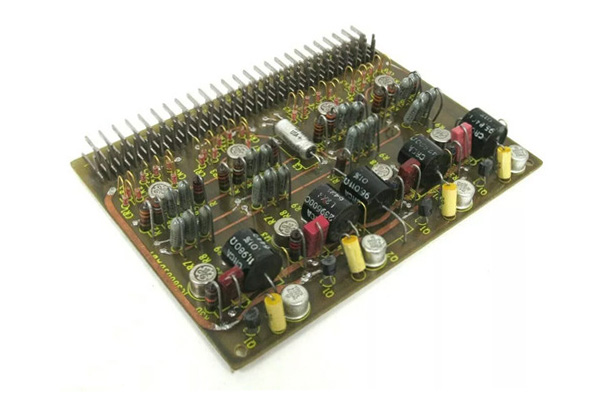

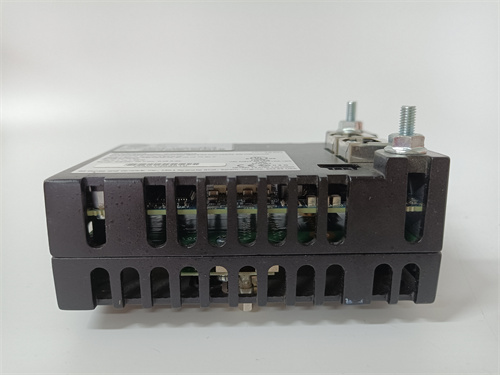

General Electric IS200TSVCH2AED MRP246517 I/O Module

Module Number:IS200TSVCH2AED MRP246517

Product status:Discontinued

Delivery time:In stock

Product status:100% new

Sales country:All over the world

Product situation:one year warranty

Product Description

The GE IS200TSVCH2AED is another module from the GE Mark VI control system, which is commonly employed in industrial applications, particularly in the field of turbine control and power generation. This specific module serves as a Turbine Steam Valve Controller and is designed to handle the control and monitoring aspects related to turbine steam valves.

Overview of GE IS200TSVCH2AED

1. Description:

– The IS200TSVCH2AED is essentially an I/O module that interfaces with turbine steam valves, providing precise control and monitoring functionality for these critical components of a turbine system.

2. Key Functions:

– Controls the operation of steam valves in gas and steam turbines, managing the flow and pressure effectively to optimize turbine performance.

– Monitors valve positions and performance metrics, ensuring that the system operates within specified parameters.

Key Features

– Analog and Digital I/O:

– Equipped with both analog and digital input/output capabilities, allowing it to connect with various sensors and actuators used in turbine steam valve operations.

– Real-Time Monitoring:

– Provides continuous feedback and diagnostic information about the status of the steam valves, improving the ability to manage potential issues proactively.

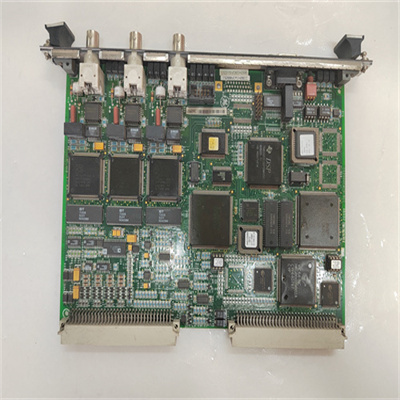

– Integration and Compatibility:

– Designed to integrate seamlessly with other components of the Mark VI control system, enhancing coordinated control across the entire control architecture.

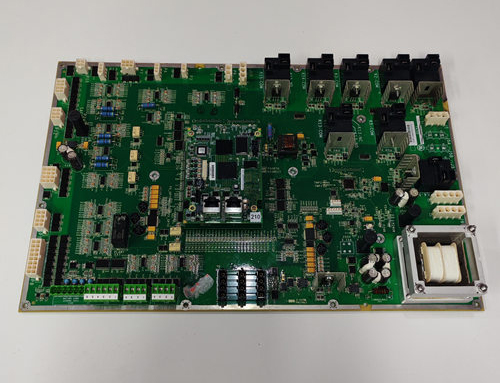

– Reliability and Redundancy:

– Features built-in redundancy and fault tolerance to ensure that critical functions remain operational even in the event of a component failure.

– User-Friendly Interface:

– Often includes indicators and interfaces that facilitate easy monitoring and adjustment by system operators.

Considerations for Use

– Installation and Configuration:

– Care should be taken during installation to follow best practices and manufacturer’s guidelines to ensure optimal performance of the module.

– Routine Maintenance:

– Regular checks and maintenance procedures are vital to ensure long-term reliability and performance. This includes monitoring diagnostics and conducting preventive measures as needed.

– Software and Firmware Updates:

– Keeping system software and firmware current is crucial for maintaining compatibility and enhancing functionality within the control system.

Conclusion

The GE IS200TSVCH2AED MRP246517 plays a vital role in managing steam valves within turbine applications. Its real-time control capabilities and diagnostic features ensure that turbine operations can be carefully monitored and managed, contributing to the overall efficiency and reliability of power generation processes.

General Electric IS200TSVCH2AED MRP246517 I/O Module

Module Number:IS200TSVCH2AED MRP246517

Product status:Discontinued

Delivery time:In stock

Product status:100% new

Sales country:All over the world

Product situation:one year warranty

Product Description

The GE IS200TSVCH2AED is another module from the GE Mark VI control system, which is commonly employed in industrial applications, particularly in the field of turbine control and power generation. This specific module serves as a Turbine Steam Valve Controller and is designed to handle the control and monitoring aspects related to turbine steam valves.

Overview of GE IS200TSVCH2AED

1. Description:

– The IS200TSVCH2AED is essentially an I/O module that interfaces with turbine steam valves, providing precise control and monitoring functionality for these critical components of a turbine system.

2. Key Functions:

– Controls the operation of steam valves in gas and steam turbines, managing the flow and pressure effectively to optimize turbine performance.

– Monitors valve positions and performance metrics, ensuring that the system operates within specified parameters.

Key Features

– Analog and Digital I/O:

– Equipped with both analog and digital input/output capabilities, allowing it to connect with various sensors and actuators used in turbine steam valve operations.

– Real-Time Monitoring:

– Provides continuous feedback and diagnostic information about the status of the steam valves, improving the ability to manage potential issues proactively.

– Integration and Compatibility:

– Designed to integrate seamlessly with other components of the Mark VI control system, enhancing coordinated control across the entire control architecture.

– Reliability and Redundancy:

– Features built-in redundancy and fault tolerance to ensure that critical functions remain operational even in the event of a component failure.

– User-Friendly Interface:

– Often includes indicators and interfaces that facilitate easy monitoring and adjustment by system operators.

Considerations for Use

– Installation and Configuration:

– Care should be taken during installation to follow best practices and manufacturer’s guidelines to ensure optimal performance of the module.

– Routine Maintenance:

– Regular checks and maintenance procedures are vital to ensure long-term reliability and performance. This includes monitoring diagnostics and conducting preventive measures as needed.

– Software and Firmware Updates:

– Keeping system software and firmware current is crucial for maintaining compatibility and enhancing functionality within the control system.

Conclusion

The GE IS200TSVCH2AED MRP246517 plays a vital role in managing steam valves within turbine applications. Its real-time control capabilities and diagnostic features ensure that turbine operations can be carefully monitored and managed, contributing to the overall efficiency and reliability of power generation processes.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...