Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

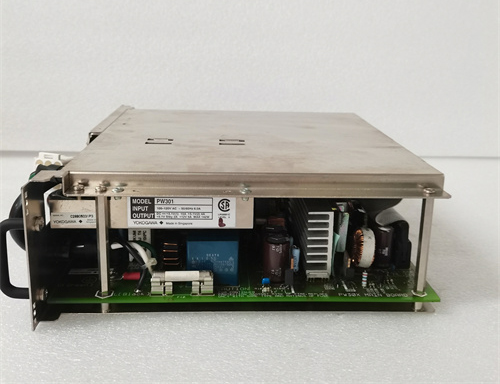

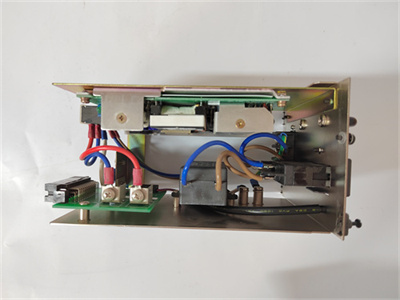

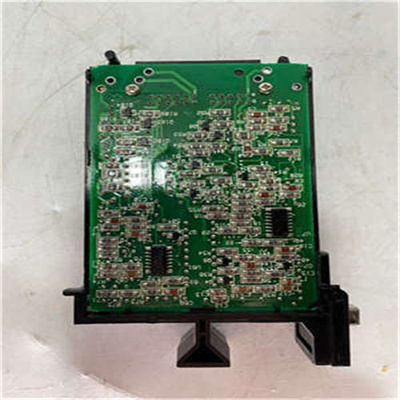

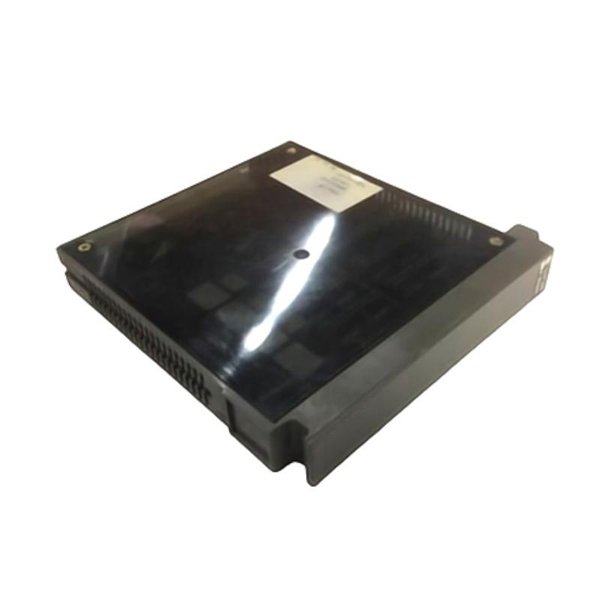

Yokogawa AFS40D-H4113 Field Control Unit

Manufacturer:Yokogawa

Product Number:AFS40D-H4113

Product Type:Field Control Unit

Origin:Japan

Dimensions:207 × 265.9 x 482.6 mm

Weight:8 kg

Views:108

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa AFS40D-H4113 Field Control Unit (FCU) is an advanced control device designed for distributed control systems (DCS) and industrial automation applications. It provides precise and reliable control of field devices, enabling real-time monitoring, data acquisition, and execution of control algorithms.

Part of the Yokogawa AFS40D series, this FCU is optimized for high-speed communication and robust performance in harsh industrial environments. It integrates seamlessly with Yokogawa’s CENTUM VP or other compatible control systems, providing stable control loops, alarm management, and diagnostic functions. The unit supports modular field networks, allowing scalable deployment in petrochemical plants, power generation, and process industries.

The AFS40D-H4113 ensures high reliability, signal integrity, and secure communication between field devices and the control system, making it a critical component for process optimization and operational safety.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | AFS40D-H4113 |

| Product Type | Field Control Unit (FCU) |

| Series | AFS40D |

| Function | Field device control, data acquisition, and communication |

| Communication Protocols | HART, FOUNDATION Fieldbus, Modbus, and proprietary Yokogawa protocols |

| Power Supply | 24 VDC typical, redundant options available |

| Input/Output Channels | Supports multiple analog and digital I/O channels |

| Response Time | <10 ms typical for control loops |

| Operating Temperature | -20 °C to +60 °C |

| Storage Temperature | -40 °C to +70 °C |

| Humidity | 5% to 95% non-condensing |

| Compliance & Standards | CE, FCC, UL, IEC standards |

| Dimensions | 207 × 265.9 x 482.6 mm |

| Weight | 8 kg |

Product Applications

The Yokogawa AFS40D-H4113 FCU is widely used across industries where precise process control and field device integration are required:

-

Distributed Control Systems (DCS): Manages field devices and control loops in CENTUM VP or other DCS platforms.

-

Power Generation: Controls turbines, boilers, and auxiliary equipment for stable and safe operation.

-

Petrochemical and Refinery Plants: Monitors and controls pumps, compressors, and valves to maintain process safety and efficiency.

-

Water and Wastewater Treatment: Ensures accurate control of pumps, sensors, and chemical dosing systems.

-

Oil and Gas Production: Integrates field instrumentation to optimize production and monitor safety systems.

-

Industrial Automation: Provides real-time data acquisition and control for various automated processes.

Product Advantages

The AFS40D-H4113 Field Control Unit offers significant advantages that improve operational efficiency, reliability, and system integration:

-

High-Speed Communication: Ensures real-time data transfer and control of field devices.

-

Modular Design: Allows scalable deployment and flexible system configuration.

-

Multi-Protocol Support: Compatible with HART, FOUNDATION Fieldbus, Modbus, and Yokogawa proprietary protocols.

-

Robust Performance: Operates reliably in harsh industrial environments with high electromagnetic interference.

-

Easy Integration: Works seamlessly with Yokogawa CENTUM VP and other control systems.

-

Precise Control: Enables fast response time (<10 ms) for critical control loops.

-

Enhanced Diagnostics: Built-in monitoring and alarm capabilities improve predictive maintenance.

-

Space and Weight Efficient: Compact design reduces installation footprint.

FAQ

-

What is the primary function of the AFS40D-H4113?

It provides control, monitoring, and communication for field devices within a distributed control system.

-

Which communication protocols are supported?

HART, FOUNDATION Fieldbus, Modbus, and Yokogawa proprietary protocols.

-

What is the typical response time of the unit?

Less than 10 ms for control loop execution.

-

Can it operate in harsh industrial environments?

Yes, it is designed to handle high EMI, temperature fluctuations, and humidity.

-

What is the operating temperature range?

-20 °C to +60 °C.

-

Is it compatible with CENTUM VP systems?

Yes, it integrates seamlessly with CENTUM VP and other compatible control systems.

-

How many I/O channels does it support?

The unit supports multiple analog and digital I/O channels; exact configuration depends on deployment.

-

Does it support redundant power supply configurations?

Yes, it can be powered by a standard 24 VDC supply with optional redundancy.

-

How does the unit contribute to predictive maintenance?

By providing accurate real-time data and diagnostics from field devices, it supports early fault detection and process optimization.

-

Which certifications and standards does it meet?

CE, FCC, UL, and IEC standards for industrial control devices.

Yokogawa AFS40D-H4113 Field Control Unit

Manufacturer:Yokogawa

Product Number:AFS40D-H4113

Product Type:Field Control Unit

Origin:Japan

Dimensions:207 × 265.9 x 482.6 mm

Weight:8 kg

Views:108

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa AFS40D-H4113 Field Control Unit (FCU) is an advanced control device designed for distributed control systems (DCS) and industrial automation applications. It provides precise and reliable control of field devices, enabling real-time monitoring, data acquisition, and execution of control algorithms.

Part of the Yokogawa AFS40D series, this FCU is optimized for high-speed communication and robust performance in harsh industrial environments. It integrates seamlessly with Yokogawa’s CENTUM VP or other compatible control systems, providing stable control loops, alarm management, and diagnostic functions. The unit supports modular field networks, allowing scalable deployment in petrochemical plants, power generation, and process industries.

The AFS40D-H4113 ensures high reliability, signal integrity, and secure communication between field devices and the control system, making it a critical component for process optimization and operational safety.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | AFS40D-H4113 |

| Product Type | Field Control Unit (FCU) |

| Series | AFS40D |

| Function | Field device control, data acquisition, and communication |

| Communication Protocols | HART, FOUNDATION Fieldbus, Modbus, and proprietary Yokogawa protocols |

| Power Supply | 24 VDC typical, redundant options available |

| Input/Output Channels | Supports multiple analog and digital I/O channels |

| Response Time | <10 ms typical for control loops |

| Operating Temperature | -20 °C to +60 °C |

| Storage Temperature | -40 °C to +70 °C |

| Humidity | 5% to 95% non-condensing |

| Compliance & Standards | CE, FCC, UL, IEC standards |

| Dimensions | 207 × 265.9 x 482.6 mm |

| Weight | 8 kg |

Product Applications

The Yokogawa AFS40D-H4113 FCU is widely used across industries where precise process control and field device integration are required:

-

Distributed Control Systems (DCS): Manages field devices and control loops in CENTUM VP or other DCS platforms.

-

Power Generation: Controls turbines, boilers, and auxiliary equipment for stable and safe operation.

-

Petrochemical and Refinery Plants: Monitors and controls pumps, compressors, and valves to maintain process safety and efficiency.

-

Water and Wastewater Treatment: Ensures accurate control of pumps, sensors, and chemical dosing systems.

-

Oil and Gas Production: Integrates field instrumentation to optimize production and monitor safety systems.

-

Industrial Automation: Provides real-time data acquisition and control for various automated processes.

Product Advantages

The AFS40D-H4113 Field Control Unit offers significant advantages that improve operational efficiency, reliability, and system integration:

-

High-Speed Communication: Ensures real-time data transfer and control of field devices.

-

Modular Design: Allows scalable deployment and flexible system configuration.

-

Multi-Protocol Support: Compatible with HART, FOUNDATION Fieldbus, Modbus, and Yokogawa proprietary protocols.

-

Robust Performance: Operates reliably in harsh industrial environments with high electromagnetic interference.

-

Easy Integration: Works seamlessly with Yokogawa CENTUM VP and other control systems.

-

Precise Control: Enables fast response time (<10 ms) for critical control loops.

-

Enhanced Diagnostics: Built-in monitoring and alarm capabilities improve predictive maintenance.

-

Space and Weight Efficient: Compact design reduces installation footprint.

FAQ

-

What is the primary function of the AFS40D-H4113?

It provides control, monitoring, and communication for field devices within a distributed control system.

-

Which communication protocols are supported?

HART, FOUNDATION Fieldbus, Modbus, and Yokogawa proprietary protocols.

-

What is the typical response time of the unit?

Less than 10 ms for control loop execution.

-

Can it operate in harsh industrial environments?

Yes, it is designed to handle high EMI, temperature fluctuations, and humidity.

-

What is the operating temperature range?

-20 °C to +60 °C.

-

Is it compatible with CENTUM VP systems?

Yes, it integrates seamlessly with CENTUM VP and other compatible control systems.

-

How many I/O channels does it support?

The unit supports multiple analog and digital I/O channels; exact configuration depends on deployment.

-

Does it support redundant power supply configurations?

Yes, it can be powered by a standard 24 VDC supply with optional redundancy.

-

How does the unit contribute to predictive maintenance?

By providing accurate real-time data and diagnostics from field devices, it supports early fault detection and process optimization.

-

Which certifications and standards does it meet?

CE, FCC, UL, and IEC standards for industrial control devices.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...