Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

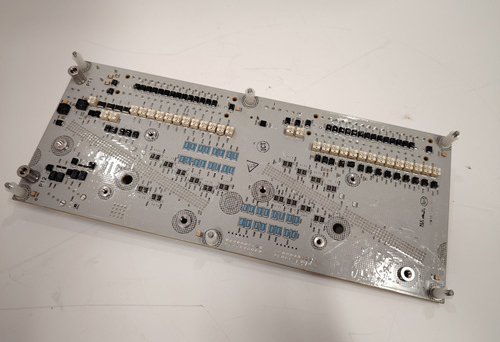

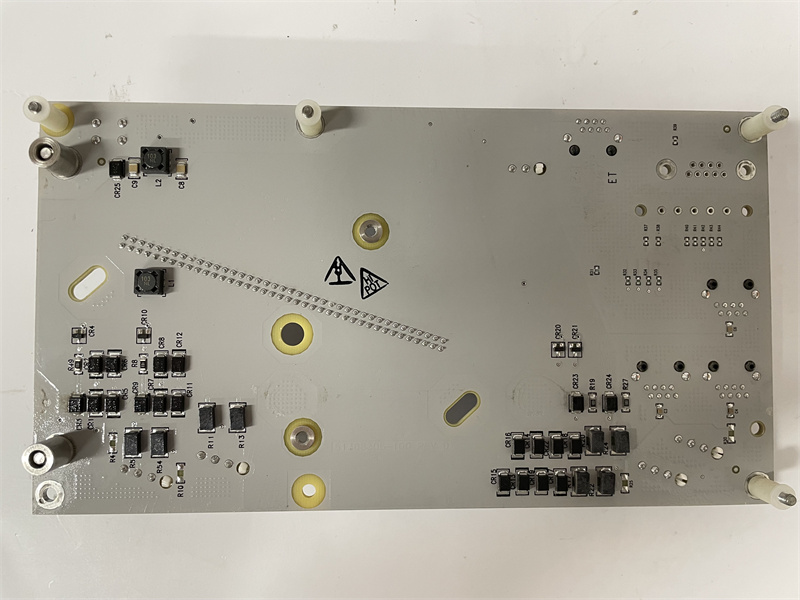

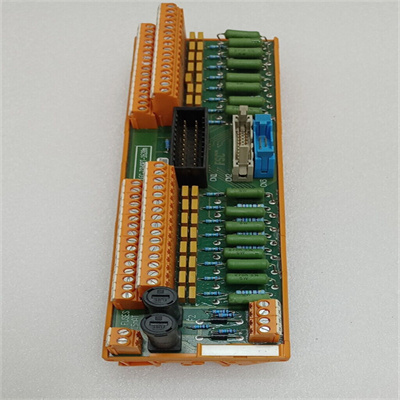

Honeywell 900C31-0244-00 HC900 C30 Controller CPU

Manufacturer:Honeywell

Product Number:900C31-0244-00

Product Type:HC900 C30 Controller CPU

Origin:USA

Dimensions:50 x 30 x 20 mm

Weight:0.15 kg

Views:49

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell 900C31-0244-00 is a high-performance HC900 C30 Controller CPU, designed to serve as the central processing unit for complex control applications in the industrial automation sector. As a core component of the HC900 Hybrid Control System, this model offers robust processing capability, a compact form factor, and excellent integration with analog, digital, and specialty I/O modules.

Well-suited for both process and thermal control environments, the 900C31-0244-00 provides a versatile solution for automation tasks across multiple industries. Whether deployed in a batch processing plant, a thermal treatment facility, or a water management station, the CPU ensures efficient and reliable control logic execution, real-time data handling, and seamless communication with SCADA or DCS systems.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 900C31-0244-00 |

| Product Type | HC900 C30 Controller CPU |

| Series | Honeywell HC900 Hybrid Control System |

| CPU Type | C30 (Standard CPU with extended firmware build) |

| Memory | 10 MB non-volatile memory |

| Maximum I/O Capacity | Up to 960 points |

| Scan Rate | ~25 ms per 100 PID loops |

| Programming Interface | Ethernet (via Hybrid Control Designer) |

| Supported Protocols | Modbus TCP, Modbus RTU (Serial), Peer-to-Peer Ethernet |

| Redundancy Support | Not supported |

| Mounting Type | DIN Rail |

| Power Supply Voltage | 24 VDC |

| Operating Temperature Range | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature Range | -40°C to 85°C (-40°F to 185°F) |

| Humidity | 5% to 95% RH, non-condensing |

| Shock and Vibration Resistance | IEC 60068 Compliant |

| Certifications | CE, UL, CSA, FM, Class I Div 2, ATEX Zone 2 |

| Dimensions (HxWxD) | 50 x 30 x 20 mm |

| Weight | 0.15 kg |

| Configuration Software | Honeywell Hybrid Control Designer |

Product Applications

The 900C31-0244-00 controller is deployed in a wide variety of process and automation environments. Key application domains include:

-

Thermal Process Control

Ovens, kilns, and furnaces that require precise, multizone temperature regulation.

-

Batch Processing in Pharmaceuticals & Chemicals

Recipe management, batch sequencing, and compliance monitoring.

-

Water and Wastewater Treatment

Regulation of pumps, valves, tank levels, and chlorine dosing systems.

-

Food & Beverage Industry

Process control in pasteurization, brewing, and automated clean-in-place (CIP) systems.

-

Boiler & Utility Control

Steam loop management, burner control, feedwater regulation, and safety interlocks.

-

HVAC and Environmental Monitoring Systems

Air quality monitoring, filtration system automation, and exhaust fan management.

Product Advantages

-

Reliable Core Control

With Honeywell’s proven architecture, the 900C31-0244-00 offers long-term operational stability and performance in mission-critical settings.

-

Scalable and Modular

Supports a wide range of input/output modules to meet the unique needs of growing applications.

-

Flexible Communication

Interoperable with both Honeywell Experion systems and third-party SCADA solutions using industry-standard protocols.

-

Rapid Processing

Efficient loop execution with typical scan rates under 25 ms for real-time control responsiveness.

-

Robust Industrial Design

Certified for use in hazardous locations, offering safe operation in ATEX and Class I Div 2 environments.

-

Simple Engineering Workflow

Easily configured with Honeywell’s Hybrid Control Designer, offering drag-and-drop programming, diagnostics, and simulation.

-

Cost-Effective

Combines DCS-level functionality with PLC flexibility at a lower total cost of ownership.

Frequently Asked Questions (FAQ)

-

Q: What does the model number 900C31-0244-00 indicate?

A: It designates a C30 CPU variant with specific firmware and licensing suited for broader or customized control functions.

-

Q: Can this controller be used in a redundant configuration?

A: No, the C30 series does not support redundancy. For that, use the HC900 C70 series CPUs.

-

Q: What software is required to program this controller?

A: Programming and configuration are performed using Honeywell’s Hybrid Control Designer (HCD).

-

Q: Is it compatible with Experion HS or PKS?

A: Yes, the controller integrates seamlessly with Honeywell’s Experion platforms.

-

Q: What are the typical control loop execution times?

A: About 25 milliseconds per 100 PID loops under normal load.

-

Q: What types of I/O modules are supported?

A: Supports analog input/output, digital input/output, thermocouple, RTD, and relay modules from the HC900 series.

-

Q: Does this model support Ethernet-based peer-to-peer communication?

A: Yes, it supports Ethernet peer-to-peer networking for controller-to-controller data exchange.

-

Q: Is remote I/O expansion possible?

A: Yes, remote I/O racks can be added using Honeywell 900R series components.

-

Q: Is the controller certified for hazardous locations?

A: Yes, it is certified for use in ATEX Zone 2 and Class I Division 2 environments.

-

Q: What happens during power loss?

A: The CPU retains its configuration in non-volatile memory and resumes normal operation when power is restored.

Honeywell 900C31-0244-00 HC900 C30 Controller CPU

Manufacturer:Honeywell

Product Number:900C31-0244-00

Product Type:HC900 C30 Controller CPU

Origin:USA

Dimensions:50 x 30 x 20 mm

Weight:0.15 kg

Views:49

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell 900C31-0244-00 is a high-performance HC900 C30 Controller CPU, designed to serve as the central processing unit for complex control applications in the industrial automation sector. As a core component of the HC900 Hybrid Control System, this model offers robust processing capability, a compact form factor, and excellent integration with analog, digital, and specialty I/O modules.

Well-suited for both process and thermal control environments, the 900C31-0244-00 provides a versatile solution for automation tasks across multiple industries. Whether deployed in a batch processing plant, a thermal treatment facility, or a water management station, the CPU ensures efficient and reliable control logic execution, real-time data handling, and seamless communication with SCADA or DCS systems.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 900C31-0244-00 |

| Product Type | HC900 C30 Controller CPU |

| Series | Honeywell HC900 Hybrid Control System |

| CPU Type | C30 (Standard CPU with extended firmware build) |

| Memory | 10 MB non-volatile memory |

| Maximum I/O Capacity | Up to 960 points |

| Scan Rate | ~25 ms per 100 PID loops |

| Programming Interface | Ethernet (via Hybrid Control Designer) |

| Supported Protocols | Modbus TCP, Modbus RTU (Serial), Peer-to-Peer Ethernet |

| Redundancy Support | Not supported |

| Mounting Type | DIN Rail |

| Power Supply Voltage | 24 VDC |

| Operating Temperature Range | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature Range | -40°C to 85°C (-40°F to 185°F) |

| Humidity | 5% to 95% RH, non-condensing |

| Shock and Vibration Resistance | IEC 60068 Compliant |

| Certifications | CE, UL, CSA, FM, Class I Div 2, ATEX Zone 2 |

| Dimensions (HxWxD) | 50 x 30 x 20 mm |

| Weight | 0.15 kg |

| Configuration Software | Honeywell Hybrid Control Designer |

Product Applications

The 900C31-0244-00 controller is deployed in a wide variety of process and automation environments. Key application domains include:

-

Thermal Process Control

Ovens, kilns, and furnaces that require precise, multizone temperature regulation.

-

Batch Processing in Pharmaceuticals & Chemicals

Recipe management, batch sequencing, and compliance monitoring.

-

Water and Wastewater Treatment

Regulation of pumps, valves, tank levels, and chlorine dosing systems.

-

Food & Beverage Industry

Process control in pasteurization, brewing, and automated clean-in-place (CIP) systems.

-

Boiler & Utility Control

Steam loop management, burner control, feedwater regulation, and safety interlocks.

-

HVAC and Environmental Monitoring Systems

Air quality monitoring, filtration system automation, and exhaust fan management.

Product Advantages

-

Reliable Core Control

With Honeywell’s proven architecture, the 900C31-0244-00 offers long-term operational stability and performance in mission-critical settings.

-

Scalable and Modular

Supports a wide range of input/output modules to meet the unique needs of growing applications.

-

Flexible Communication

Interoperable with both Honeywell Experion systems and third-party SCADA solutions using industry-standard protocols.

-

Rapid Processing

Efficient loop execution with typical scan rates under 25 ms for real-time control responsiveness.

-

Robust Industrial Design

Certified for use in hazardous locations, offering safe operation in ATEX and Class I Div 2 environments.

-

Simple Engineering Workflow

Easily configured with Honeywell’s Hybrid Control Designer, offering drag-and-drop programming, diagnostics, and simulation.

-

Cost-Effective

Combines DCS-level functionality with PLC flexibility at a lower total cost of ownership.

Frequently Asked Questions (FAQ)

-

Q: What does the model number 900C31-0244-00 indicate?

A: It designates a C30 CPU variant with specific firmware and licensing suited for broader or customized control functions.

-

Q: Can this controller be used in a redundant configuration?

A: No, the C30 series does not support redundancy. For that, use the HC900 C70 series CPUs.

-

Q: What software is required to program this controller?

A: Programming and configuration are performed using Honeywell’s Hybrid Control Designer (HCD).

-

Q: Is it compatible with Experion HS or PKS?

A: Yes, the controller integrates seamlessly with Honeywell’s Experion platforms.

-

Q: What are the typical control loop execution times?

A: About 25 milliseconds per 100 PID loops under normal load.

-

Q: What types of I/O modules are supported?

A: Supports analog input/output, digital input/output, thermocouple, RTD, and relay modules from the HC900 series.

-

Q: Does this model support Ethernet-based peer-to-peer communication?

A: Yes, it supports Ethernet peer-to-peer networking for controller-to-controller data exchange.

-

Q: Is remote I/O expansion possible?

A: Yes, remote I/O racks can be added using Honeywell 900R series components.

-

Q: Is the controller certified for hazardous locations?

A: Yes, it is certified for use in ATEX Zone 2 and Class I Division 2 environments.

-

Q: What happens during power loss?

A: The CPU retains its configuration in non-volatile memory and resumes normal operation when power is restored.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...