Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

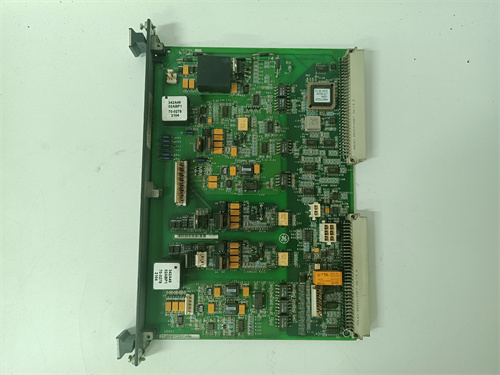

GE Fanuc 5136-PFB-VME PLC Module

Manufacturer:General Electric

Part Number:5136-PFB-VME

Product Type:PLC Module

Series:GE Speedtronic Mark V

Stock:IN STOCK

Repair:3-7 Day

Rush Repair:24-48 Hrs.

Warranty:3 Years

Dimensions:2.1 cm x 20.2 cm x 26.1 cm

Weight:0.27 k

Product Description

The GE Fanuc 5136-PFB-VME module is a specialized PLC designed for industrial tasks, especially in the plastics industry. It is widely used in injection molding machines to control the process of applying plastic handles to containers, such as milk and juice jugs.

Key Applications and Features

- Injection Molding: Controls plastic handle application for consistent quality and production rates.

- VersaMax Micro PLC: Uses a 14-point VersaMax Micro PLC for efficient control and monitoring.

- Dual Jug Handling: Simultaneously handles two jugs, increasing overall productivity.

- Flexible Feeding: Supports both continuous and random jug feeding for greater flexibility.

- Size Range: Accommodates jugs from one quart to one gallon in size.

- Handle Heating: Ensures optimal handle application by heating them to the right temperature.

- Diagnostic Capabilities: Alerts users when the supply of handles is low or depleted, improving efficiency.

Technical Specifications

The GE Fanuc 5136-PFB-VME module’s technical details vary slightly based on configuration, but here are some common specifications:

- VMEbus Interface: Connects to the VMEbus backplane for system integration.

- I/O Capabilities: Provides digital and analog I/O points for controlling machine components.

- Communication: Supports various communication protocols to interface with other devices.

- Programming: Programmed using proprietary or standard industrial languages like ladder logic.

- Environmental Considerations: Designed for industrial environments, meeting temperature, humidity, and vibration standards.

GE Fanuc 5136-PFB-VME PLC Module

Manufacturer:General Electric

Part Number:5136-PFB-VME

Product Type:PLC Module

Series:GE Speedtronic Mark V

Stock:IN STOCK

Repair:3-7 Day

Rush Repair:24-48 Hrs.

Warranty:3 Years

Dimensions:2.1 cm x 20.2 cm x 26.1 cm

Weight:0.27 k

Product Description

The GE Fanuc 5136-PFB-VME module is a specialized PLC designed for industrial tasks, especially in the plastics industry. It is widely used in injection molding machines to control the process of applying plastic handles to containers, such as milk and juice jugs.

Key Applications and Features

- Injection Molding: Controls plastic handle application for consistent quality and production rates.

- VersaMax Micro PLC: Uses a 14-point VersaMax Micro PLC for efficient control and monitoring.

- Dual Jug Handling: Simultaneously handles two jugs, increasing overall productivity.

- Flexible Feeding: Supports both continuous and random jug feeding for greater flexibility.

- Size Range: Accommodates jugs from one quart to one gallon in size.

- Handle Heating: Ensures optimal handle application by heating them to the right temperature.

- Diagnostic Capabilities: Alerts users when the supply of handles is low or depleted, improving efficiency.

Technical Specifications

The GE Fanuc 5136-PFB-VME module’s technical details vary slightly based on configuration, but here are some common specifications:

- VMEbus Interface: Connects to the VMEbus backplane for system integration.

- I/O Capabilities: Provides digital and analog I/O points for controlling machine components.

- Communication: Supports various communication protocols to interface with other devices.

- Programming: Programmed using proprietary or standard industrial languages like ladder logic.

- Environmental Considerations: Designed for industrial environments, meeting temperature, humidity, and vibration standards.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...