Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

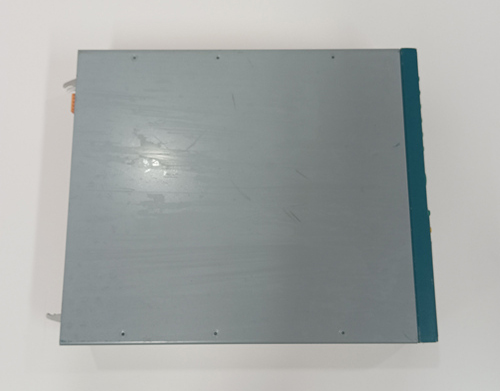

Bently Nevada 330104-00-05-50-11-00 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330104-00-05-50-11-00

Condition:3300 XL 8 mm Proximity Probe

Origin:USA

Cable length:5 m

Weight:1.615 kg

Views:24

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330104-00-05-50-11-00 is a high-performance vibration monitoring transducer designed for industrial applications. It is part of the Bently Nevada 3300 series, renowned for its reliability and precision in machinery protection and condition monitoring. This transducer is commonly used in critical rotating equipment such as turbines, compressors, and pumps to detect vibration and ensure operational safety.

Product Parameters

The table below outlines the key specifications of the Bently Nevada 330104-00-05-50-11-00:

| Parameter | Specification |

|---|---|

| Model Number | 330104-00-05-50-11-00 |

| Type | Vibration Transducer |

| Measurement Range | 0-500 µm (peak-to-peak) |

| Frequency Response | 10 Hz to 1 kHz |

| Sensitivity | 8 mV/µm (±5%) |

| Output Signal | 4-20 mA or voltage (configurable) |

| Power Supply | 18-30 VDC |

| Operating Temperature | -40°C to +85°C (-40°F to +185°F) |

| Housing Material | Stainless Steel |

| Protection Rating | IP67 |

| Cable length | 5 m |

| Weight | 1.615 kg |

| Mounting | Threaded or flange mounting |

Product Applications

The Bently Nevada 330104-00-05-50-11-00 is widely used in industries where machinery health monitoring is critical. Key applications include:

-

Power Generation: Monitoring turbines, generators, and auxiliary equipment.

-

Oil & Gas: Protecting compressors, pumps, and pipelines from vibration-related failures.

-

Chemical Processing: Ensuring safe operation of rotating machinery in hazardous environments.

-

Water Treatment: Monitoring pumps and motors to prevent downtime.

-

Manufacturing: Detecting imbalances or misalignments in production line equipment.

Product Advantages

-

High Accuracy: Provides precise vibration measurements for early fault detection.

-

Robust Construction: Stainless steel housing ensures durability in harsh environments.

-

Wide Temperature Range: Operates reliably in extreme temperatures.

-

Easy Integration: Compatible with most control systems and monitoring platforms.

-

Low Maintenance: Designed for long-term use with minimal servicing.

-

IP67 Protection: Resists dust and water ingress, suitable for outdoor use.

Frequently Asked Questions (FAQ)

-

What is the operating voltage range of the 330104-00-05-50-11-00?

The transducer operates on 18-30 VDC.

-

Can this transducer be used in explosive environments?

Yes, with additional certifications (e.g., ATEX or IECEx), it can be used in hazardous areas.

-

What is the typical lifespan of this transducer?

With proper installation and maintenance, it can last 5+ years.

-

How do I calibrate the 330104-00-05-50-11-00?

Calibration requires a signal generator and oscilloscope; refer to the manual for detailed steps.

-

Is the output signal configurable?

Yes, it can be configured for 4-20 mA or voltage output.

-

What is the maximum vibration range it can measure?

The maximum range is 500 µm (peak-to-peak).

-

Can it be mounted vertically or horizontally?

Yes, the transducer can be mounted in any orientation.

-

Does it require external signal conditioning?

No, it has built-in signal conditioning for direct integration.

-

What is the warranty period?

Typically 12 months, depending on the supplier.

-

How do I troubleshoot a faulty transducer?

Check power supply, wiring, and output signal; if issues persist, contact Bently Nevada support.

Bently Nevada 330104-00-05-50-11-00 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330104-00-05-50-11-00

Condition:3300 XL 8 mm Proximity Probe

Origin:USA

Cable length:5 m

Weight:1.615 kg

Views:24

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330104-00-05-50-11-00 is a high-performance vibration monitoring transducer designed for industrial applications. It is part of the Bently Nevada 3300 series, renowned for its reliability and precision in machinery protection and condition monitoring. This transducer is commonly used in critical rotating equipment such as turbines, compressors, and pumps to detect vibration and ensure operational safety.

Product Parameters

The table below outlines the key specifications of the Bently Nevada 330104-00-05-50-11-00:

| Parameter | Specification |

|---|---|

| Model Number | 330104-00-05-50-11-00 |

| Type | Vibration Transducer |

| Measurement Range | 0-500 µm (peak-to-peak) |

| Frequency Response | 10 Hz to 1 kHz |

| Sensitivity | 8 mV/µm (±5%) |

| Output Signal | 4-20 mA or voltage (configurable) |

| Power Supply | 18-30 VDC |

| Operating Temperature | -40°C to +85°C (-40°F to +185°F) |

| Housing Material | Stainless Steel |

| Protection Rating | IP67 |

| Cable length | 5 m |

| Weight | 1.615 kg |

| Mounting | Threaded or flange mounting |

Product Applications

The Bently Nevada 330104-00-05-50-11-00 is widely used in industries where machinery health monitoring is critical. Key applications include:

-

Power Generation: Monitoring turbines, generators, and auxiliary equipment.

-

Oil & Gas: Protecting compressors, pumps, and pipelines from vibration-related failures.

-

Chemical Processing: Ensuring safe operation of rotating machinery in hazardous environments.

-

Water Treatment: Monitoring pumps and motors to prevent downtime.

-

Manufacturing: Detecting imbalances or misalignments in production line equipment.

Product Advantages

-

High Accuracy: Provides precise vibration measurements for early fault detection.

-

Robust Construction: Stainless steel housing ensures durability in harsh environments.

-

Wide Temperature Range: Operates reliably in extreme temperatures.

-

Easy Integration: Compatible with most control systems and monitoring platforms.

-

Low Maintenance: Designed for long-term use with minimal servicing.

-

IP67 Protection: Resists dust and water ingress, suitable for outdoor use.

Frequently Asked Questions (FAQ)

-

What is the operating voltage range of the 330104-00-05-50-11-00?

The transducer operates on 18-30 VDC.

-

Can this transducer be used in explosive environments?

Yes, with additional certifications (e.g., ATEX or IECEx), it can be used in hazardous areas.

-

What is the typical lifespan of this transducer?

With proper installation and maintenance, it can last 5+ years.

-

How do I calibrate the 330104-00-05-50-11-00?

Calibration requires a signal generator and oscilloscope; refer to the manual for detailed steps.

-

Is the output signal configurable?

Yes, it can be configured for 4-20 mA or voltage output.

-

What is the maximum vibration range it can measure?

The maximum range is 500 µm (peak-to-peak).

-

Can it be mounted vertically or horizontally?

Yes, the transducer can be mounted in any orientation.

-

Does it require external signal conditioning?

No, it has built-in signal conditioning for direct integration.

-

What is the warranty period?

Typically 12 months, depending on the supplier.

-

How do I troubleshoot a faulty transducer?

Check power supply, wiring, and output signal; if issues persist, contact Bently Nevada support.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...