Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

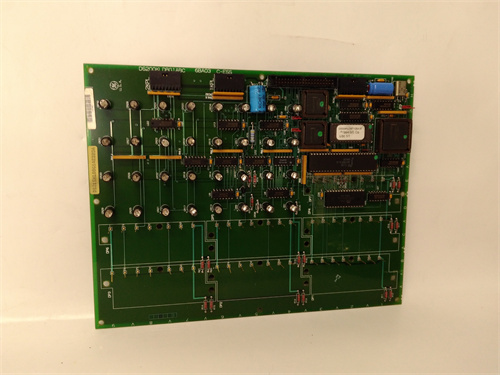

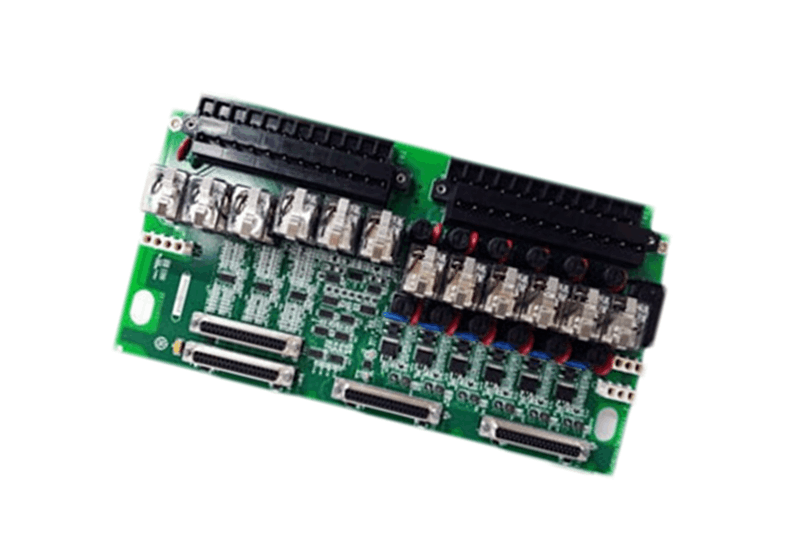

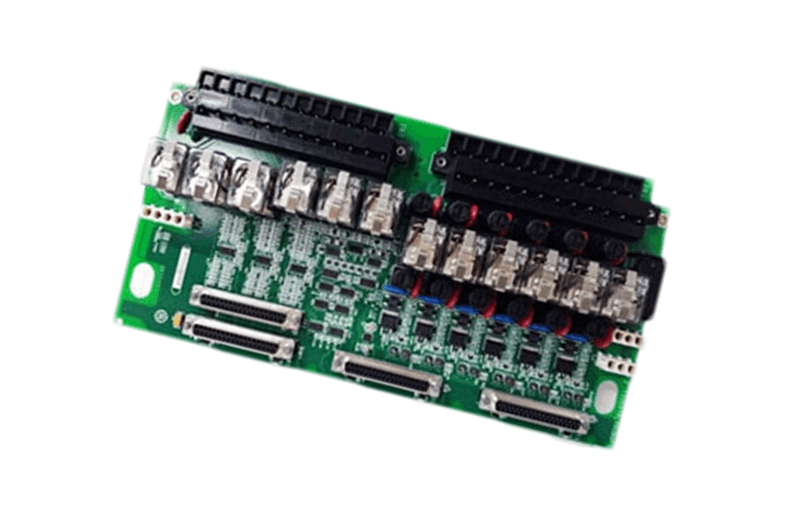

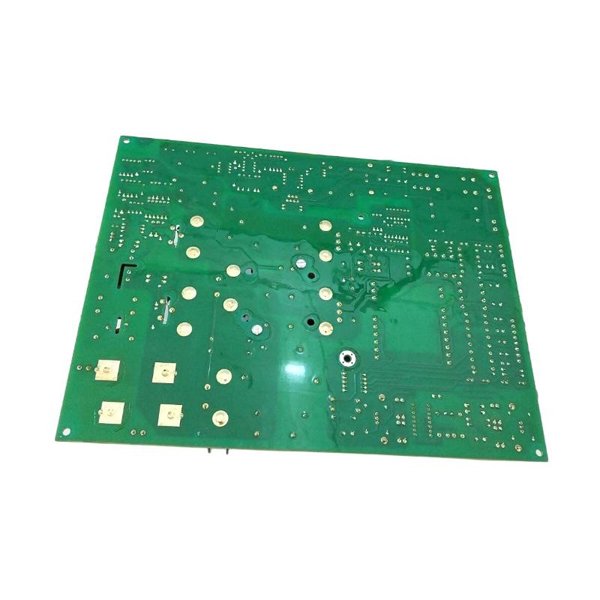

General Electric IS210AEPSG1AFC Power Board

Manufacturer:GE

Product Number:IS210AEPSG1AFC

Product Type:Power Board

Origin:USA

Dimensions:180 × 100 × 35 mm

Weight:0.5 kg

Views:14

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS210AEPSG1AFC Power Board is a high-reliability power conversion and distribution module designed for GE Mark VIe and related control systems. Engineered to deliver stable and regulated power to critical control electronics, this board incorporates advanced protection features, robust circuit design, and long-term durability. It serves as the primary interface between incoming plant power sources and sensitive control hardware, ensuring continuous operation even in harsh industrial environments such as power generation, petrochemical, and heavy manufacturing facilities.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | IS210AEPSG1AFC |

| Series | GE Mark VIe / Mark VI Control Platform |

| Function | Power supply, conversion, and regulated distribution |

| Input Voltage Range | 90–264 V AC (universal input) |

| Output Voltages | +24 V DC, +5 V DC, ±15 V DC (isolated outputs) |

| Power Rating | 250 W continuous, peak up to 300 W |

| Efficiency | >85 % typical at full load |

| Protection Features | Over-voltage, over-current, thermal shutdown, surge suppression |

| Cooling Method | Convection and forced-air compatible |

| Operating Temperature | –40 °C to +70 °C |

| Humidity Range | 0–95 % non-condensing |

| Vibration Tolerance | Up to 5 g, 10–2000 Hz |

| Shock Resistance | 30 g, 11 ms half-sine |

| Monitoring Features | Built-in diagnostics, status LEDs, remote health reporting |

| Dimensions (W×H×D) | 180 × 100 × 35 mm |

| Weight | 0.5 kg |

| Mounting | Rack or panel mount with secure grounding |

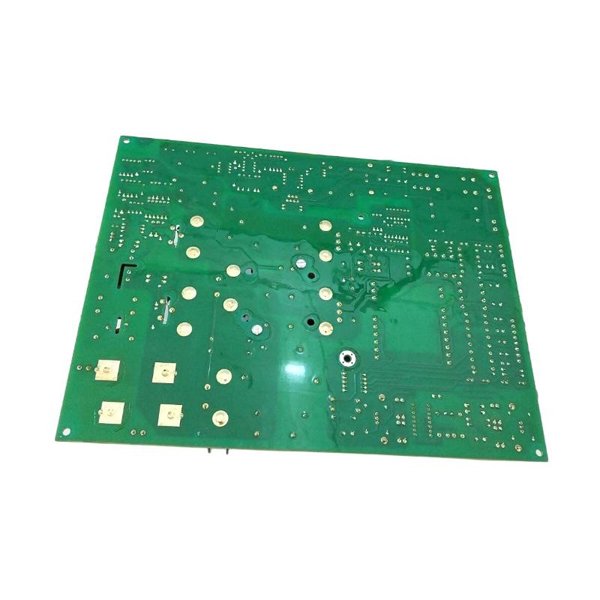

| Board Material | FR4 PCB with multilayer copper planes and conformal coating |

Applications

The IS210AEPSG1AFC is a versatile power interface board used across a wide range of industries:

-

Gas and Steam Turbine Control Systems: Provides stable low-voltage DC supplies for Mark VIe controllers and I/O modules.

-

Industrial Automation: Powers distributed control subsystems requiring noise-free DC power.

-

Power Generation Plants: Ensures continuous operation of protection relays, sensors, and communication modules.

-

Process Control Facilities: Supplies regulated power to sensitive instrumentation and PLC hardware.

-

Oil & Gas Infrastructure: Maintains uninterrupted power to SCADA and turbine monitoring equipment.

Advantages

-

High Efficiency & Stability: Delivers clean, tightly regulated output voltages with minimal ripple for optimal control-system performance.

-

Comprehensive Protection: Integrated surge suppression, over-current and over-voltage safeguards extend component life.

-

Built-In Diagnostics: Real-time health monitoring with LED indicators simplifies troubleshooting and preventive maintenance.

-

Wide Input Range: Supports global AC mains voltages, enabling deployment in diverse regions without modification.

-

Robust Construction: Rugged PCB design with conformal coating ensures reliable operation in demanding industrial environments.

-

Scalable Integration: Seamlessly fits into Mark VIe architecture or other GE control platforms.

Frequently Asked Questions (FAQ)

-

What type of isolation is used between input and output circuits?

The board employs high-frequency transformer isolation with reinforced insulation to meet industrial safety standards.

-

How does the board manage inrush current at power-up?

A soft-start circuit limits inrush current, reducing stress on upstream breakers and contactors.

-

What kind of filtering is provided for output ripple reduction?

Multi-stage LC filters and low-ESR capacitors ensure ripple is maintained well below 50 mV.

-

Can this board operate in parallel with another power supply for redundancy?

Yes, it supports current-sharing operation when configured with appropriate Mark VIe redundancy settings.

-

How is over-temperature protection implemented?

Thermistors and temperature sensors trigger an automatic shutdown when internal temperatures exceed safe thresholds.

-

Does the board support remote monitoring through the Mark VIe system?

Yes, output voltage, current, and fault data can be accessed via the system’s diagnostic interface.

-

What EMI suppression techniques are integrated?

Common-mode chokes, ferrite beads, and shielded traces minimize electromagnetic interference.

-

How does the module handle sudden line voltage fluctuations?

Input surge suppressors and wide-range AC/DC conversion circuitry maintain stable output during transients.

-

What is the typical response time for load regulation?

Less than 1 ms to maintain voltage within ±2 % during abrupt load changes.

-

Is hot-swap replacement supported?

Yes, the board is designed for hot-swap maintenance within a de-energized backplane segment.

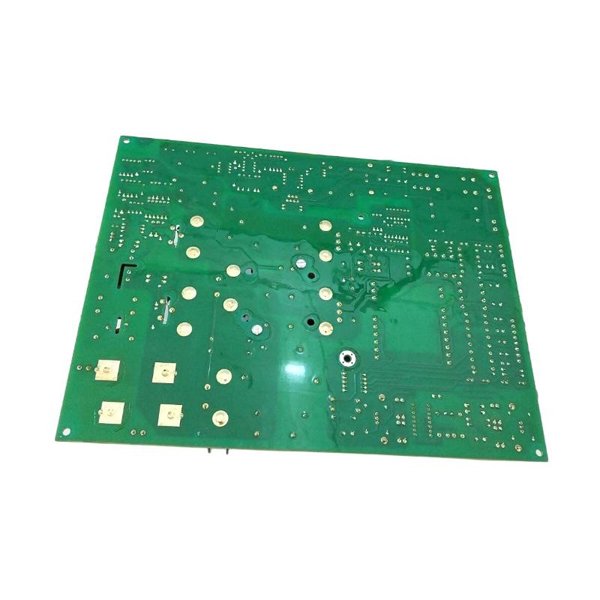

General Electric IS210AEPSG1AFC Power Board

Manufacturer:GE

Product Number:IS210AEPSG1AFC

Product Type:Power Board

Origin:USA

Dimensions:180 × 100 × 35 mm

Weight:0.5 kg

Views:14

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS210AEPSG1AFC Power Board is a high-reliability power conversion and distribution module designed for GE Mark VIe and related control systems. Engineered to deliver stable and regulated power to critical control electronics, this board incorporates advanced protection features, robust circuit design, and long-term durability. It serves as the primary interface between incoming plant power sources and sensitive control hardware, ensuring continuous operation even in harsh industrial environments such as power generation, petrochemical, and heavy manufacturing facilities.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | IS210AEPSG1AFC |

| Series | GE Mark VIe / Mark VI Control Platform |

| Function | Power supply, conversion, and regulated distribution |

| Input Voltage Range | 90–264 V AC (universal input) |

| Output Voltages | +24 V DC, +5 V DC, ±15 V DC (isolated outputs) |

| Power Rating | 250 W continuous, peak up to 300 W |

| Efficiency | >85 % typical at full load |

| Protection Features | Over-voltage, over-current, thermal shutdown, surge suppression |

| Cooling Method | Convection and forced-air compatible |

| Operating Temperature | –40 °C to +70 °C |

| Humidity Range | 0–95 % non-condensing |

| Vibration Tolerance | Up to 5 g, 10–2000 Hz |

| Shock Resistance | 30 g, 11 ms half-sine |

| Monitoring Features | Built-in diagnostics, status LEDs, remote health reporting |

| Dimensions (W×H×D) | 180 × 100 × 35 mm |

| Weight | 0.5 kg |

| Mounting | Rack or panel mount with secure grounding |

| Board Material | FR4 PCB with multilayer copper planes and conformal coating |

Applications

The IS210AEPSG1AFC is a versatile power interface board used across a wide range of industries:

-

Gas and Steam Turbine Control Systems: Provides stable low-voltage DC supplies for Mark VIe controllers and I/O modules.

-

Industrial Automation: Powers distributed control subsystems requiring noise-free DC power.

-

Power Generation Plants: Ensures continuous operation of protection relays, sensors, and communication modules.

-

Process Control Facilities: Supplies regulated power to sensitive instrumentation and PLC hardware.

-

Oil & Gas Infrastructure: Maintains uninterrupted power to SCADA and turbine monitoring equipment.

Advantages

-

High Efficiency & Stability: Delivers clean, tightly regulated output voltages with minimal ripple for optimal control-system performance.

-

Comprehensive Protection: Integrated surge suppression, over-current and over-voltage safeguards extend component life.

-

Built-In Diagnostics: Real-time health monitoring with LED indicators simplifies troubleshooting and preventive maintenance.

-

Wide Input Range: Supports global AC mains voltages, enabling deployment in diverse regions without modification.

-

Robust Construction: Rugged PCB design with conformal coating ensures reliable operation in demanding industrial environments.

-

Scalable Integration: Seamlessly fits into Mark VIe architecture or other GE control platforms.

Frequently Asked Questions (FAQ)

-

What type of isolation is used between input and output circuits?

The board employs high-frequency transformer isolation with reinforced insulation to meet industrial safety standards.

-

How does the board manage inrush current at power-up?

A soft-start circuit limits inrush current, reducing stress on upstream breakers and contactors.

-

What kind of filtering is provided for output ripple reduction?

Multi-stage LC filters and low-ESR capacitors ensure ripple is maintained well below 50 mV.

-

Can this board operate in parallel with another power supply for redundancy?

Yes, it supports current-sharing operation when configured with appropriate Mark VIe redundancy settings.

-

How is over-temperature protection implemented?

Thermistors and temperature sensors trigger an automatic shutdown when internal temperatures exceed safe thresholds.

-

Does the board support remote monitoring through the Mark VIe system?

Yes, output voltage, current, and fault data can be accessed via the system’s diagnostic interface.

-

What EMI suppression techniques are integrated?

Common-mode chokes, ferrite beads, and shielded traces minimize electromagnetic interference.

-

How does the module handle sudden line voltage fluctuations?

Input surge suppressors and wide-range AC/DC conversion circuitry maintain stable output during transients.

-

What is the typical response time for load regulation?

Less than 1 ms to maintain voltage within ±2 % during abrupt load changes.

-

Is hot-swap replacement supported?

Yes, the board is designed for hot-swap maintenance within a de-energized backplane segment.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...