Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

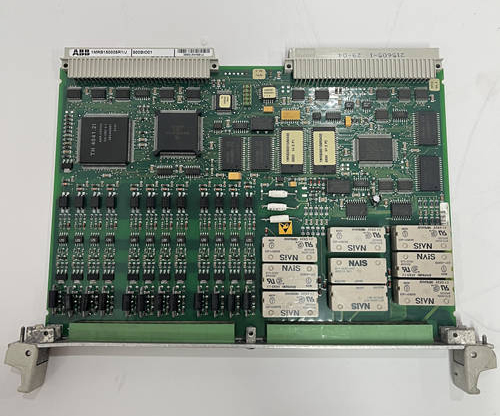

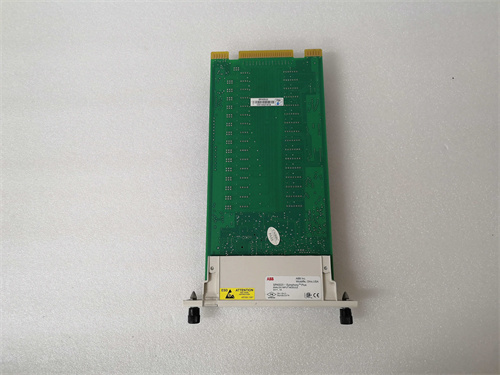

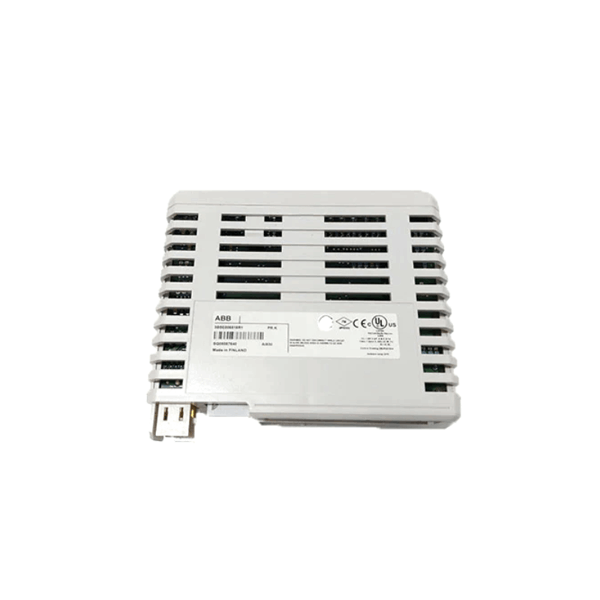

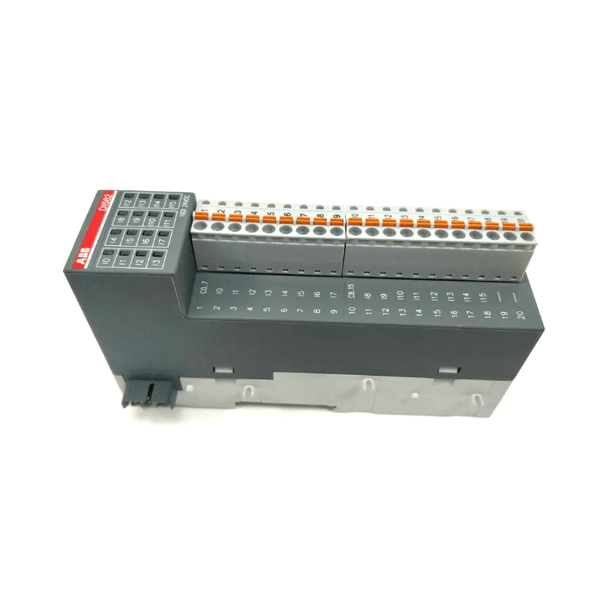

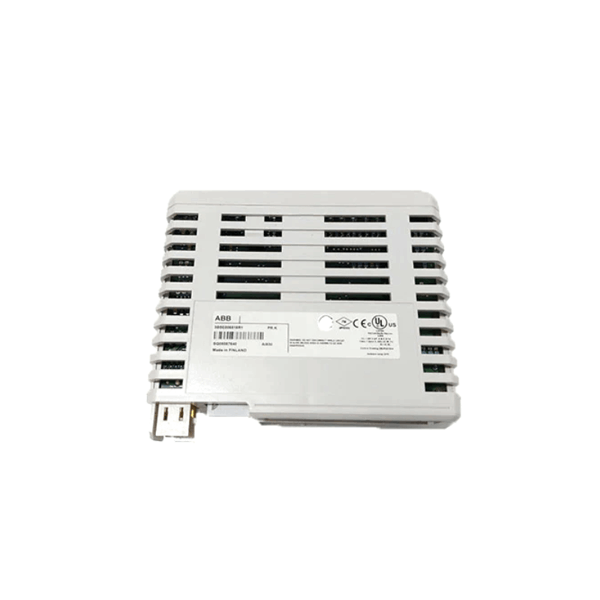

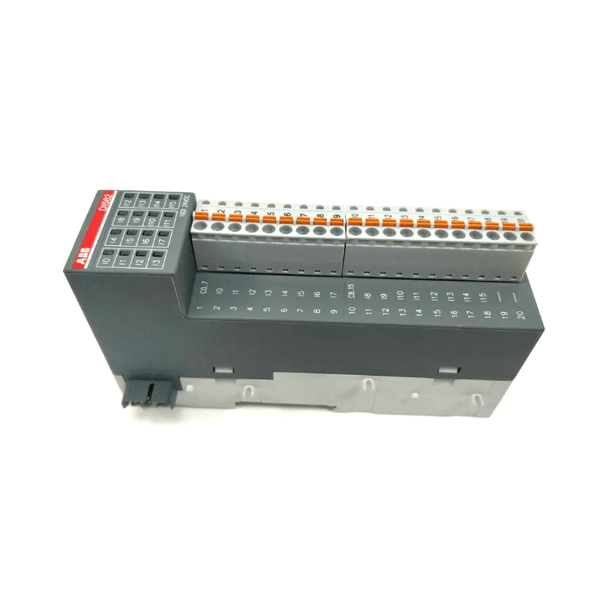

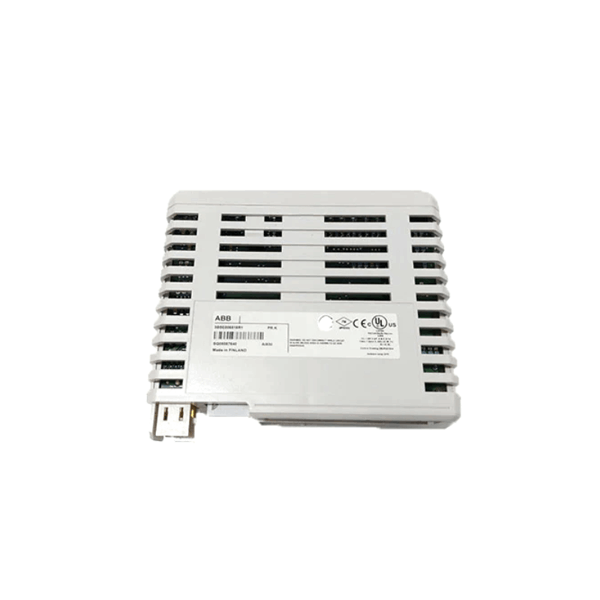

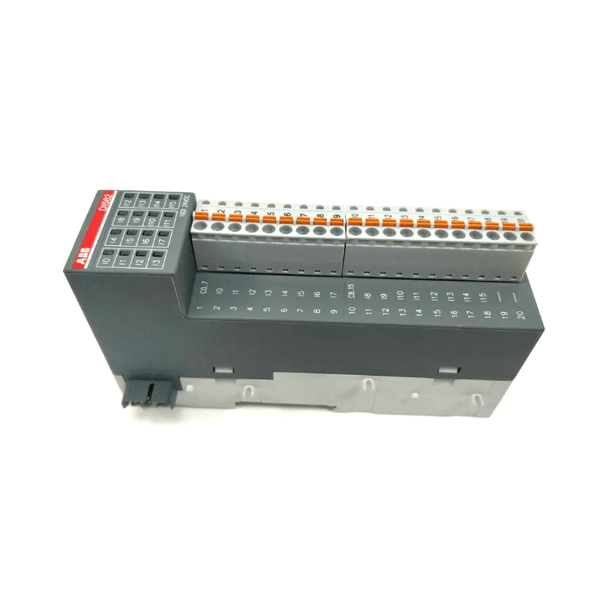

ABB TP853 3BSE018126R1 Baseplate

Manufacturer:ABB

Product Number:TP853 3BSE018126R1

Product Type:Baseplate

Origin:Sweden

Dimensions:162 x 63 x 45 mm

Weight:0.5 kg

Views:45

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB TP853 3BSE018126R1 Baseplate is a robust and industrial-grade mounting base designed to serve the AC 800M and S800 I/O platforms, part of ABB’s powerful and modular automation control system family. Its primary function is to securely mount I/O modules while ensuring stable electrical connectivity and efficient internal communication across modules in distributed control systems (DCS).

The TP853 is engineered for high-density industrial installations, where precision, long-term mechanical stability, and modular scalability are essential. Its form factor and construction materials are optimized for demanding environments in sectors such as energy, chemical, petrochemical, utilities, and manufacturing. This baseplate is designed for seamless integration into ABB’s 800xA control environment, providing a reliable mechanical interface between terminal units and electronic modules.

Product Specifications

| Parameter | Details |

|---|---|

| Product Name | TP853 Baseplate |

| Part Number | 3BSE018126R1 |

| Product Type | Mounting Baseplate |

| Compatible Systems | ABB AC 800M, S800 I/O, 800xA systems |

| Mounting Method | DIN rail or panel mounting |

| Material | Industrial-grade steel with protective powder coating |

| Number of Module Slots | Typically supports 8 S800 I/O modules |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +70°C |

| Relative Humidity | 5% to 95%, non-condensing |

| Ingress Protection | IP20 |

| Certifications | CE, RoHS compliant |

| Dimensions (W×H×D) | 162 x 63 x 45 mm |

| Weight | 0.5 kg |

Product Applications

The TP853 is deployed across a wide range of industries where modular and scalable automation systems are required. Major application areas include:

-

Power Generation and Distribution

Used in substations and power plants for reliable module mounting and expansion in control systems.

-

Oil & Gas Processing

Supports modules in upstream and downstream automation, including pipeline control and refinery systems.

-

Water and Wastewater Treatment

Ensures structured and secure module integration in automated treatment processes.

-

Pharmaceutical and Chemical Plants

Provides robust support for critical I/O components in hazardous and highly regulated environments.

-

Manufacturing and Assembly Lines

Offers compact and efficient module placement within high-speed production automation systems.

-

Metals and Mining Automation

Facilitates reliable control architecture for heavy-duty, vibration-intensive industrial settings.

Product Advantages

-

Mechanical Robustness

Constructed with reinforced materials, offering superior vibration resistance and long-term durability.

-

Precision Alignment

Built-in guide mechanisms ensure secure and aligned module installation, reducing connection errors.

-

Easy Integration

Modular design simplifies expansion, retrofitting, and maintenance tasks.

-

Compact Footprint

High module density support makes it ideal for control cabinets with space constraints.

-

Efficient Signal Routing

Designed to ensure consistent and interference-free communication between installed modules.

-

Environmental Resilience

Withstands industrial temperature and humidity ranges without mechanical or structural degradation.

-

Simplified Maintenance

Enables rapid module swaps without requiring full system shutdown.

-

Universal Compatibility

Fully supports a wide range of ABB terminal units and I/O modules.

-

Standards-Compliant Design

Meets all relevant CE and RoHS standards, ensuring reliability in safety-sensitive environments.

-

Field-Proven

Widely used in mission-critical control architectures globally, with high reliability.

Frequently Asked Questions (FAQ)

-

What modules are compatible with the ABB TP853 baseplate?

The TP853 supports S800 I/O modules such as AI810, DI810, AO810, and DO810, as well as communication modules and certain AC 800M components.

-

Can TP853 be used in redundant controller configurations?

Yes, it can be incorporated into redundant architectures with appropriate modules, aiding fault tolerance in mission-critical systems.

-

What is the difference between TP851 and TP853 baseplates?

TP853 typically supports more modules and may offer improved layout spacing or electrical routing compared to TP851. Always consult module documentation for specific layout advantages.

-

How should the TP853 be grounded?

Proper grounding is achieved via the control panel or backplane bonding. Always follow ABB grounding guidelines for safety and EMC compliance.

-

Does TP853 come with built-in diagnostics?

No, the baseplate itself does not have diagnostics, but it supports modules with advanced diagnostic capabilities.

-

Is TP853 suitable for field installation?

It is suitable for control cabinets located in the field but must be installed within an enclosure due to its IP20 rating.

-

What is the recommended orientation for installation?

It can be installed horizontally or vertically, depending on the cabinet design and cooling airflow.

-

Can this baseplate be used in ATEX environments?

While TP853 is not ATEX certified on its own, it can be used in ATEX Zone 2 areas when integrated into certified system assemblies.

-

Is there a need for ventilation space around the baseplate?

Yes, a minimum clearance (typically 25 mm) should be maintained for proper airflow and heat dissipation.

-

What should I do if the baseplate becomes damaged during service?

Damaged baseplates must be replaced to ensure the integrity of module connections and mounting. Always use ABB original parts for replacements.

ABB TP853 3BSE018126R1 Baseplate

Manufacturer:ABB

Product Number:TP853 3BSE018126R1

Product Type:Baseplate

Origin:Sweden

Dimensions:162 x 63 x 45 mm

Weight:0.5 kg

Views:45

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB TP853 3BSE018126R1 Baseplate is a robust and industrial-grade mounting base designed to serve the AC 800M and S800 I/O platforms, part of ABB’s powerful and modular automation control system family. Its primary function is to securely mount I/O modules while ensuring stable electrical connectivity and efficient internal communication across modules in distributed control systems (DCS).

The TP853 is engineered for high-density industrial installations, where precision, long-term mechanical stability, and modular scalability are essential. Its form factor and construction materials are optimized for demanding environments in sectors such as energy, chemical, petrochemical, utilities, and manufacturing. This baseplate is designed for seamless integration into ABB’s 800xA control environment, providing a reliable mechanical interface between terminal units and electronic modules.

Product Specifications

| Parameter | Details |

|---|---|

| Product Name | TP853 Baseplate |

| Part Number | 3BSE018126R1 |

| Product Type | Mounting Baseplate |

| Compatible Systems | ABB AC 800M, S800 I/O, 800xA systems |

| Mounting Method | DIN rail or panel mounting |

| Material | Industrial-grade steel with protective powder coating |

| Number of Module Slots | Typically supports 8 S800 I/O modules |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +70°C |

| Relative Humidity | 5% to 95%, non-condensing |

| Ingress Protection | IP20 |

| Certifications | CE, RoHS compliant |

| Dimensions (W×H×D) | 162 x 63 x 45 mm |

| Weight | 0.5 kg |

Product Applications

The TP853 is deployed across a wide range of industries where modular and scalable automation systems are required. Major application areas include:

-

Power Generation and Distribution

Used in substations and power plants for reliable module mounting and expansion in control systems.

-

Oil & Gas Processing

Supports modules in upstream and downstream automation, including pipeline control and refinery systems.

-

Water and Wastewater Treatment

Ensures structured and secure module integration in automated treatment processes.

-

Pharmaceutical and Chemical Plants

Provides robust support for critical I/O components in hazardous and highly regulated environments.

-

Manufacturing and Assembly Lines

Offers compact and efficient module placement within high-speed production automation systems.

-

Metals and Mining Automation

Facilitates reliable control architecture for heavy-duty, vibration-intensive industrial settings.

Product Advantages

-

Mechanical Robustness

Constructed with reinforced materials, offering superior vibration resistance and long-term durability.

-

Precision Alignment

Built-in guide mechanisms ensure secure and aligned module installation, reducing connection errors.

-

Easy Integration

Modular design simplifies expansion, retrofitting, and maintenance tasks.

-

Compact Footprint

High module density support makes it ideal for control cabinets with space constraints.

-

Efficient Signal Routing

Designed to ensure consistent and interference-free communication between installed modules.

-

Environmental Resilience

Withstands industrial temperature and humidity ranges without mechanical or structural degradation.

-

Simplified Maintenance

Enables rapid module swaps without requiring full system shutdown.

-

Universal Compatibility

Fully supports a wide range of ABB terminal units and I/O modules.

-

Standards-Compliant Design

Meets all relevant CE and RoHS standards, ensuring reliability in safety-sensitive environments.

-

Field-Proven

Widely used in mission-critical control architectures globally, with high reliability.

Frequently Asked Questions (FAQ)

-

What modules are compatible with the ABB TP853 baseplate?

The TP853 supports S800 I/O modules such as AI810, DI810, AO810, and DO810, as well as communication modules and certain AC 800M components.

-

Can TP853 be used in redundant controller configurations?

Yes, it can be incorporated into redundant architectures with appropriate modules, aiding fault tolerance in mission-critical systems.

-

What is the difference between TP851 and TP853 baseplates?

TP853 typically supports more modules and may offer improved layout spacing or electrical routing compared to TP851. Always consult module documentation for specific layout advantages.

-

How should the TP853 be grounded?

Proper grounding is achieved via the control panel or backplane bonding. Always follow ABB grounding guidelines for safety and EMC compliance.

-

Does TP853 come with built-in diagnostics?

No, the baseplate itself does not have diagnostics, but it supports modules with advanced diagnostic capabilities.

-

Is TP853 suitable for field installation?

It is suitable for control cabinets located in the field but must be installed within an enclosure due to its IP20 rating.

-

What is the recommended orientation for installation?

It can be installed horizontally or vertically, depending on the cabinet design and cooling airflow.

-

Can this baseplate be used in ATEX environments?

While TP853 is not ATEX certified on its own, it can be used in ATEX Zone 2 areas when integrated into certified system assemblies.

-

Is there a need for ventilation space around the baseplate?

Yes, a minimum clearance (typically 25 mm) should be maintained for proper airflow and heat dissipation.

-

What should I do if the baseplate becomes damaged during service?

Damaged baseplates must be replaced to ensure the integrity of module connections and mounting. Always use ABB original parts for replacements.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...