Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

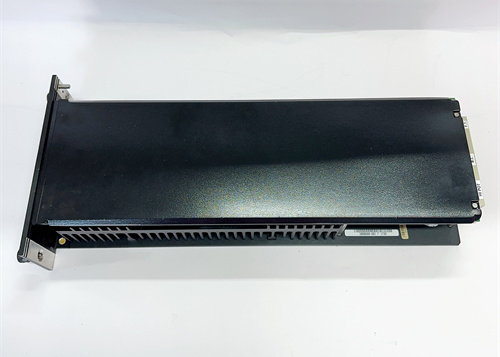

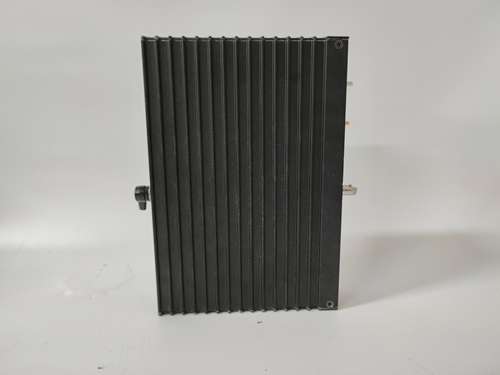

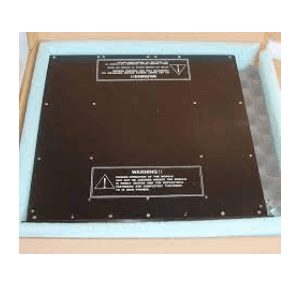

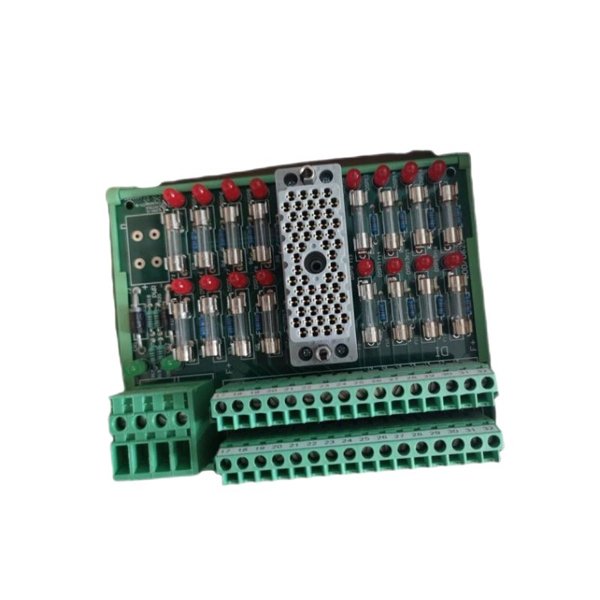

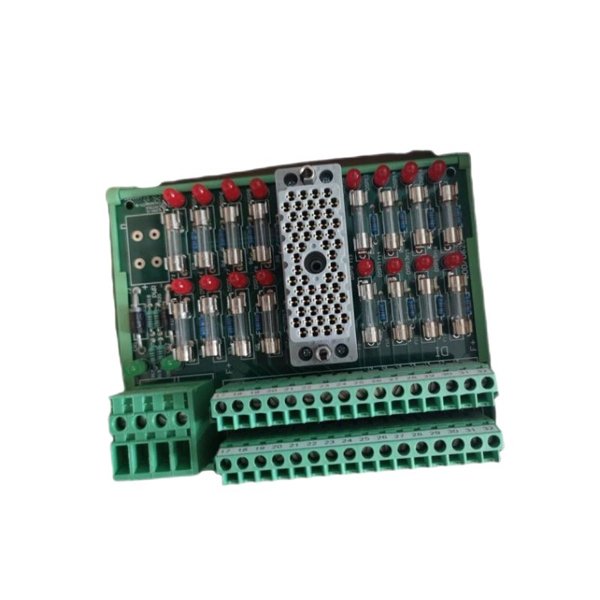

Triconex 9563-810NJ Digital Input Terminal Panel

Manufacturer:Triconex

Product Number:9563-810NJ

Condition:Digital Input Terminal Panel

Origin:USA

Dimensions:114.3 ×127 × 107.95 mm

Weight:0.38 kg

Views:46

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Triconex 9563-810NJ is a highly reliable and advanced safety system module from the Triconex product line. Designed for use in critical safety applications, the 9563-810NJ provides top-tier functionality for ensuring secure and efficient control of process industries. It supports various operational conditions with minimal maintenance needs, making it a preferred choice for critical infrastructure. Whether used in oil and gas, petrochemical, or other industrial sectors, this module ensures robust performance and safety.

Product Specifications

| Specification | Details |

|---|---|

| Model | Triconex 9563-810NJ |

| Weight | 0.38 kg |

| Dimensions | 114.3 ×127 × 107.95 mm |

| Operating Voltage | 24V DC |

| Current Consumption | 0.5 A |

| Input Channels | 8 digital input channels |

| Output Channels | 4 digital output channels |

| Communication | Modbus, TCP/IP |

| Environmental Range | -20°C to 60°C |

| Enclosure Type | DIN Rail Mounted |

| Certification | UL, CE, SIL-3 certified |

| Power Consumption | 12W |

Product Applications

The Triconex 9563-810NJ is ideal for mission-critical industries requiring high-level safety control. Its applications include:

-

Oil & Gas: Safe shutdown systems, emergency stop systems, and control of hazardous equipment.

-

Petrochemical: Control of industrial processes with safety requirements like high-temperature and pressure protection.

-

Power Generation: Safety systems for electrical grid protection and plant equipment monitoring.

-

Chemical Processing: Monitoring and control of chemicals in plants to ensure safe operations.

Advantages

-

Reliability: The Triconex 9563-810NJ is built to meet the highest standards of operational reliability, offering peace of mind for long-term, trouble-free use.

-

Safety Compliance: It complies with SIL-3 (Safety Integrity Level), making it perfect for high-risk environments that require rigorous safety standards.

-

Durability: Designed for extreme conditions, it can withstand harsh industrial environments, including varying temperatures, vibrations, and humidity levels.

-

Modular Design: The system is modular, making it easily customizable for different application needs without requiring extensive system changes.

-

Ease of Integration: With support for standard communication protocols like Modbus and TCP/IP, it can be seamlessly integrated into existing systems, reducing setup time and cost.

-

Scalable: It supports a range of configurations, allowing for easy scalability as your system or plant grows.

-

Maintenance-Friendly: The system is designed for minimal maintenance, with self-diagnostics and fault detection that reduce downtime and operational disruption.

FAQs

Q1: What industries is the Triconex 9563-810NJ suitable for?

A1: The 9563-810NJ is suitable for industries like oil and gas, petrochemical, power generation, and chemical processing where safety and control are critical.

Q2: How does this module ensure safety compliance?

A2: It meets SIL-3 safety requirements, ensuring that the system can handle high-risk tasks without compromising safety standards.

Q3: What communication protocols are supported by the Triconex 9563-810NJ?

A3: The module supports Modbus and TCP/IP protocols for seamless integration with other systems.

Q4: What are the power requirements for this module?

A4: The Triconex 9563-810NJ operates at a 24V DC power supply and consumes 12W of power.

Q5: What is the temperature range for operation?

A5: The module can operate in temperatures ranging from -20°C to 60°C, making it suitable for most industrial environments.

Q6: How many input and output channels does it have?

A6: It features 8 digital input channels and 4 digital output channels for versatile control.

Q7: How is the Triconex 9563-810NJ mounted?

A7: The module is designed to be DIN Rail Mounted, allowing for easy installation and space-saving.

Q8: What certifications does the product have?

A8: The Triconex 9563-810NJ is UL, CE, and SIL-3 certified, ensuring it meets global safety and quality standards.

Q9: Is the system easy to maintain?

A9: Yes, the system is designed for minimal maintenance, with built-in self-diagnostics and fault detection to keep downtime to a minimum.

Q10: Can this module be integrated with other safety systems?

A10: Yes, it can be integrated with other systems through its support for Modbus and TCP/IP communication protocols.

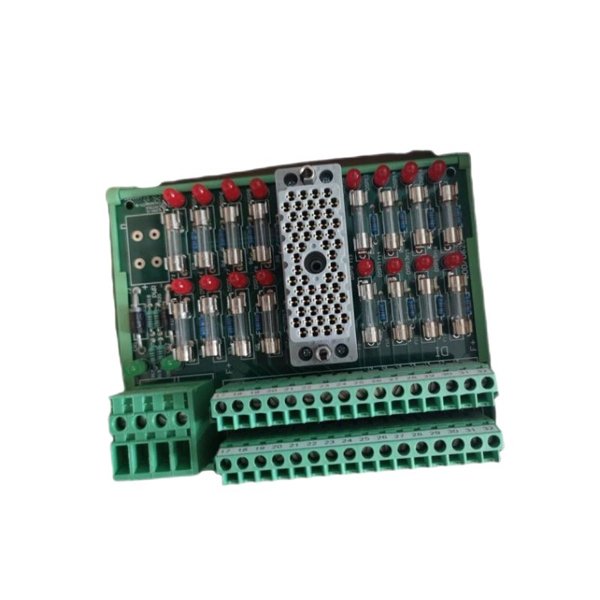

Triconex 9563-810NJ Digital Input Terminal Panel

Manufacturer:Triconex

Product Number:9563-810NJ

Condition:Digital Input Terminal Panel

Origin:USA

Dimensions:114.3 ×127 × 107.95 mm

Weight:0.38 kg

Views:46

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Triconex 9563-810NJ is a highly reliable and advanced safety system module from the Triconex product line. Designed for use in critical safety applications, the 9563-810NJ provides top-tier functionality for ensuring secure and efficient control of process industries. It supports various operational conditions with minimal maintenance needs, making it a preferred choice for critical infrastructure. Whether used in oil and gas, petrochemical, or other industrial sectors, this module ensures robust performance and safety.

Product Specifications

| Specification | Details |

|---|---|

| Model | Triconex 9563-810NJ |

| Weight | 0.38 kg |

| Dimensions | 114.3 ×127 × 107.95 mm |

| Operating Voltage | 24V DC |

| Current Consumption | 0.5 A |

| Input Channels | 8 digital input channels |

| Output Channels | 4 digital output channels |

| Communication | Modbus, TCP/IP |

| Environmental Range | -20°C to 60°C |

| Enclosure Type | DIN Rail Mounted |

| Certification | UL, CE, SIL-3 certified |

| Power Consumption | 12W |

Product Applications

The Triconex 9563-810NJ is ideal for mission-critical industries requiring high-level safety control. Its applications include:

-

Oil & Gas: Safe shutdown systems, emergency stop systems, and control of hazardous equipment.

-

Petrochemical: Control of industrial processes with safety requirements like high-temperature and pressure protection.

-

Power Generation: Safety systems for electrical grid protection and plant equipment monitoring.

-

Chemical Processing: Monitoring and control of chemicals in plants to ensure safe operations.

Advantages

-

Reliability: The Triconex 9563-810NJ is built to meet the highest standards of operational reliability, offering peace of mind for long-term, trouble-free use.

-

Safety Compliance: It complies with SIL-3 (Safety Integrity Level), making it perfect for high-risk environments that require rigorous safety standards.

-

Durability: Designed for extreme conditions, it can withstand harsh industrial environments, including varying temperatures, vibrations, and humidity levels.

-

Modular Design: The system is modular, making it easily customizable for different application needs without requiring extensive system changes.

-

Ease of Integration: With support for standard communication protocols like Modbus and TCP/IP, it can be seamlessly integrated into existing systems, reducing setup time and cost.

-

Scalable: It supports a range of configurations, allowing for easy scalability as your system or plant grows.

-

Maintenance-Friendly: The system is designed for minimal maintenance, with self-diagnostics and fault detection that reduce downtime and operational disruption.

FAQs

Q1: What industries is the Triconex 9563-810NJ suitable for?

A1: The 9563-810NJ is suitable for industries like oil and gas, petrochemical, power generation, and chemical processing where safety and control are critical.

Q2: How does this module ensure safety compliance?

A2: It meets SIL-3 safety requirements, ensuring that the system can handle high-risk tasks without compromising safety standards.

Q3: What communication protocols are supported by the Triconex 9563-810NJ?

A3: The module supports Modbus and TCP/IP protocols for seamless integration with other systems.

Q4: What are the power requirements for this module?

A4: The Triconex 9563-810NJ operates at a 24V DC power supply and consumes 12W of power.

Q5: What is the temperature range for operation?

A5: The module can operate in temperatures ranging from -20°C to 60°C, making it suitable for most industrial environments.

Q6: How many input and output channels does it have?

A6: It features 8 digital input channels and 4 digital output channels for versatile control.

Q7: How is the Triconex 9563-810NJ mounted?

A7: The module is designed to be DIN Rail Mounted, allowing for easy installation and space-saving.

Q8: What certifications does the product have?

A8: The Triconex 9563-810NJ is UL, CE, and SIL-3 certified, ensuring it meets global safety and quality standards.

Q9: Is the system easy to maintain?

A9: Yes, the system is designed for minimal maintenance, with built-in self-diagnostics and fault detection to keep downtime to a minimum.

Q10: Can this module be integrated with other safety systems?

A10: Yes, it can be integrated with other systems through its support for Modbus and TCP/IP communication protocols.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...