Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

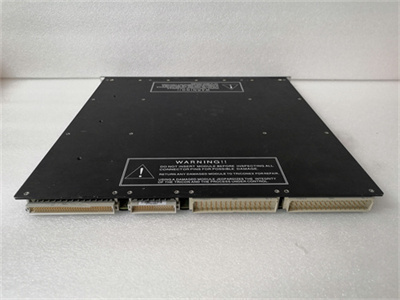

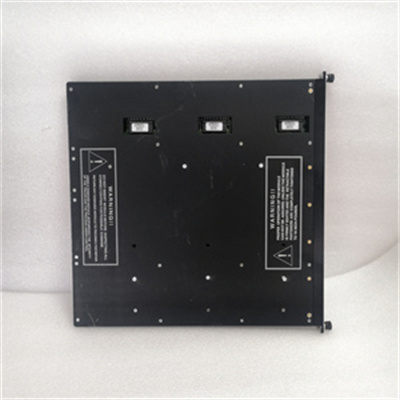

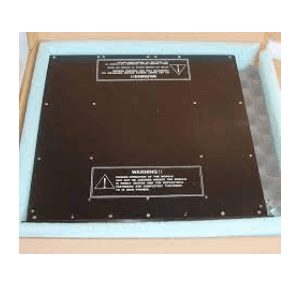

Triconex 8101 Extended Chassis

Manufacturer:Triconex

Product Number:8101

Product Type:Extended Chassis

Origin:USA

Dimensions:483 x 578 x 451 mm

Weight:19.7 kg

Views:69

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

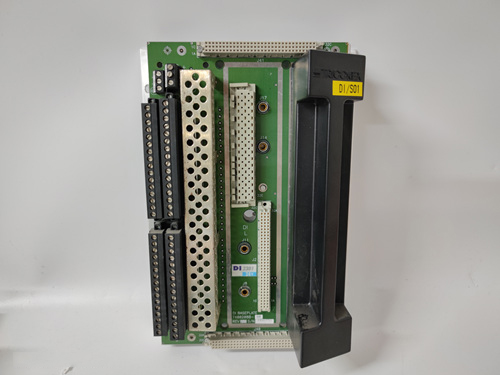

The Triconex 8101 Extended Chassis is a rugged, modular platform designed specifically for Triconex safety systems. It serves as an extended housing unit that accommodates multiple processor and I/O modules, providing enhanced scalability and flexibility for complex safety instrumented systems (SIS). This chassis is engineered to support demanding industrial environments where reliability and fault tolerance are critical.

Constructed with high-quality materials and built to stringent industrial standards, the 8101 chassis ensures robust protection of internal components. Its extended design allows for more module slots compared to standard chassis, enabling larger configurations for expanded safety applications. The chassis supports hot-swappable modules, simplifying maintenance and minimizing downtime.

Product Specifications

| Parameter | Specification |

|---|---|

| Product Model | Triconex 8101 Extended Chassis |

| Type | Extended Rack/Chassis |

| Number of Slots | 12 Module Slots |

| Supported Modules | Processor, I/O, Communication Modules |

| Power Supply | 24 V DC (External Power Supply Required) |

| Dimensions (H × W × D) | 483 x 578 x 451 mm |

| Weight | 19.7 kg |

| Mounting | Rack-mounted / Panel-mounted |

| Operating Temperature Range | -20°C to +70°C |

| Cooling | Convection Cooling (Fan optional) |

| Material | Steel Chassis with Powder Coating |

| Compliance | IEC 61508 SIL 3 Certified Compatible |

Applications

-

Process Safety Instrumented Systems (SIS): Acts as a backbone chassis for deploying Triconex controllers and I/O modules in process industries such as chemical plants, refineries, and power generation.

-

Critical Infrastructure: Provides high-reliability safety control for power plants, oil & gas platforms, and water treatment facilities.

-

Manufacturing Automation: Used in automotive, pharmaceuticals, and heavy manufacturing plants for reliable safety monitoring and control.

-

Redundant Safety Architectures: Supports triple modular redundancy and fault-tolerant configurations critical for SIL 3 safety requirements.

-

Energy Sector: Facilitates safety control systems in nuclear and conventional power stations.

-

Remote Monitoring & Control: Suitable for integration with remote I/O and communication modules in distributed control environments.

Product Advantages

-

High Scalability: The 12-slot extended design allows users to build larger, more complex safety systems without compromising footprint efficiency.

-

Robust Build Quality: Heavy-duty steel chassis ensures excellent mechanical protection and durability in harsh industrial conditions.

-

Fault Tolerance: Designed to support triple modular redundant (TMR) architecture for superior system reliability.

-

Ease of Maintenance: Hot-swappable modules reduce downtime and simplify maintenance processes.

-

Flexible Installation: Supports both rack and panel mounting, adapting to diverse plant layouts.

-

Comprehensive Compatibility: Compatible with a broad range of Triconex modules, including latest-generation processors and communication interfaces.

-

Thermal Management: Effective convection cooling, with options for fan-assisted cooling in high-temperature environments.

-

Industry Compliance: Meets or exceeds international safety standards including IEC 61508 SIL 3, ensuring regulatory compliance.

-

Optimized Footprint: Extended chassis provides more slots within a compact form factor, optimizing space use.

-

Enhanced Safety: Helps maintain system integrity through robust hardware and fault isolation.

Frequently Asked Questions (FAQ)

-

How many modules can the Triconex 8101 chassis accommodate?

It can hold up to 12 modules, including processors and I/O cards.

-

What are the dimensions and weight of the chassis?

Dimensions are 483 x 578 x 451 mm, and weight is 19.7 kg.

-

Can the modules be replaced without shutting down the entire system?

Yes, it supports hot-swappable modules to minimize downtime.

-

What type of power supply is required?

The chassis requires an external 24 V DC power supply.

-

Is the chassis suitable for harsh industrial environments?

Absolutely. It is built from steel with powder coating for corrosion resistance.

-

What temperature range can it operate in?

It functions reliably between -20°C and +70°C.

-

Does it support triple modular redundancy (TMR)?

Yes, it is designed for TMR configurations critical to safety systems.

-

Can it be mounted in different ways?

Yes, it supports both rack and panel mounting options.

-

Is the chassis compliant with safety standards?

It is IEC 61508 SIL 3 compatible, ensuring compliance for safety applications.

-

What cooling methods does it support?

It primarily uses convection cooling; fans can be added if needed.

Triconex 8101 Extended Chassis

Manufacturer:Triconex

Product Number:8101

Product Type:Extended Chassis

Origin:USA

Dimensions:483 x 578 x 451 mm

Weight:19.7 kg

Views:69

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Triconex 8101 Extended Chassis is a rugged, modular platform designed specifically for Triconex safety systems. It serves as an extended housing unit that accommodates multiple processor and I/O modules, providing enhanced scalability and flexibility for complex safety instrumented systems (SIS). This chassis is engineered to support demanding industrial environments where reliability and fault tolerance are critical.

Constructed with high-quality materials and built to stringent industrial standards, the 8101 chassis ensures robust protection of internal components. Its extended design allows for more module slots compared to standard chassis, enabling larger configurations for expanded safety applications. The chassis supports hot-swappable modules, simplifying maintenance and minimizing downtime.

Product Specifications

| Parameter | Specification |

|---|---|

| Product Model | Triconex 8101 Extended Chassis |

| Type | Extended Rack/Chassis |

| Number of Slots | 12 Module Slots |

| Supported Modules | Processor, I/O, Communication Modules |

| Power Supply | 24 V DC (External Power Supply Required) |

| Dimensions (H × W × D) | 483 x 578 x 451 mm |

| Weight | 19.7 kg |

| Mounting | Rack-mounted / Panel-mounted |

| Operating Temperature Range | -20°C to +70°C |

| Cooling | Convection Cooling (Fan optional) |

| Material | Steel Chassis with Powder Coating |

| Compliance | IEC 61508 SIL 3 Certified Compatible |

Applications

-

Process Safety Instrumented Systems (SIS): Acts as a backbone chassis for deploying Triconex controllers and I/O modules in process industries such as chemical plants, refineries, and power generation.

-

Critical Infrastructure: Provides high-reliability safety control for power plants, oil & gas platforms, and water treatment facilities.

-

Manufacturing Automation: Used in automotive, pharmaceuticals, and heavy manufacturing plants for reliable safety monitoring and control.

-

Redundant Safety Architectures: Supports triple modular redundancy and fault-tolerant configurations critical for SIL 3 safety requirements.

-

Energy Sector: Facilitates safety control systems in nuclear and conventional power stations.

-

Remote Monitoring & Control: Suitable for integration with remote I/O and communication modules in distributed control environments.

Product Advantages

-

High Scalability: The 12-slot extended design allows users to build larger, more complex safety systems without compromising footprint efficiency.

-

Robust Build Quality: Heavy-duty steel chassis ensures excellent mechanical protection and durability in harsh industrial conditions.

-

Fault Tolerance: Designed to support triple modular redundant (TMR) architecture for superior system reliability.

-

Ease of Maintenance: Hot-swappable modules reduce downtime and simplify maintenance processes.

-

Flexible Installation: Supports both rack and panel mounting, adapting to diverse plant layouts.

-

Comprehensive Compatibility: Compatible with a broad range of Triconex modules, including latest-generation processors and communication interfaces.

-

Thermal Management: Effective convection cooling, with options for fan-assisted cooling in high-temperature environments.

-

Industry Compliance: Meets or exceeds international safety standards including IEC 61508 SIL 3, ensuring regulatory compliance.

-

Optimized Footprint: Extended chassis provides more slots within a compact form factor, optimizing space use.

-

Enhanced Safety: Helps maintain system integrity through robust hardware and fault isolation.

Frequently Asked Questions (FAQ)

-

How many modules can the Triconex 8101 chassis accommodate?

It can hold up to 12 modules, including processors and I/O cards.

-

What are the dimensions and weight of the chassis?

Dimensions are 483 x 578 x 451 mm, and weight is 19.7 kg.

-

Can the modules be replaced without shutting down the entire system?

Yes, it supports hot-swappable modules to minimize downtime.

-

What type of power supply is required?

The chassis requires an external 24 V DC power supply.

-

Is the chassis suitable for harsh industrial environments?

Absolutely. It is built from steel with powder coating for corrosion resistance.

-

What temperature range can it operate in?

It functions reliably between -20°C and +70°C.

-

Does it support triple modular redundancy (TMR)?

Yes, it is designed for TMR configurations critical to safety systems.

-

Can it be mounted in different ways?

Yes, it supports both rack and panel mounting options.

-

Is the chassis compliant with safety standards?

It is IEC 61508 SIL 3 compatible, ensuring compliance for safety applications.

-

What cooling methods does it support?

It primarily uses convection cooling; fans can be added if needed.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...