Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

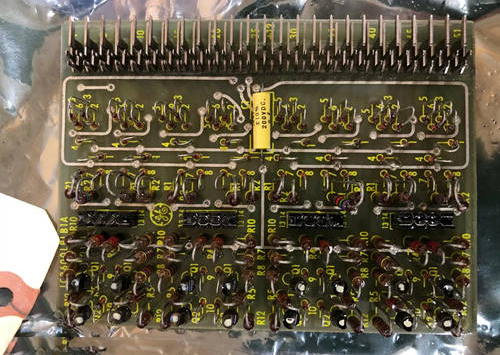

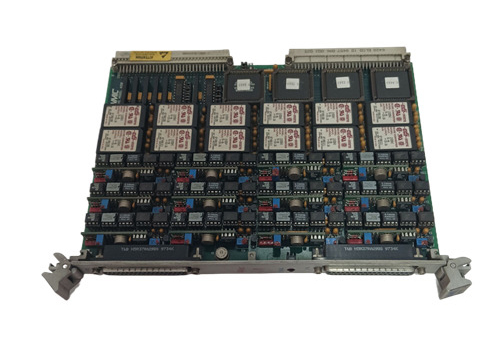

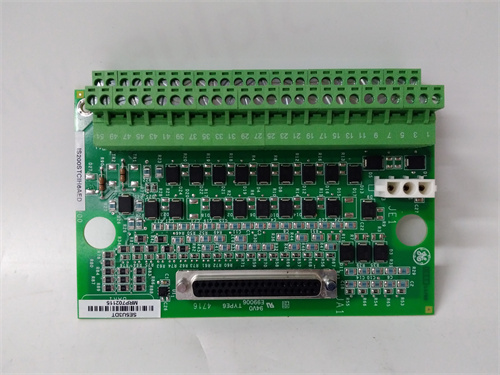

General Electric IC693PCM311 Programmable Coprocessor Module

Manufacturer:GE

Product Number:IC693PCM311

Product Type:Programmable Coprocessor Module

Origin:USA

Dimensions:140 x 140 x 35 mm

Weight:0.449 kg

Views:32

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IC693PCM311 Programmable Coprocessor Module (PCM) is a high-performance coprocessor specifically designed to expand the capabilities of the GE Fanuc Series 90-30 PLC system. It operates as an independent processing unit within the PLC rack, capable of executing complex algorithms, handling advanced communications, and managing demanding data processing tasks that would otherwise burden the main PLC CPU.

Built around a fast Intel 80C186 processor, the IC693PCM311 is engineered to allow users to develop and deploy custom programs using C, C++, or BASIC. It supports two serial ports (RS-232/RS-485), making it ideal for communicating with a wide variety of external devices—including drives, sensors, printers, bar code readers, HMIs, and legacy equipment.

This flexible module allows plant operators and system integrators to extend the functionality of their Series 90-30 PLC without needing expensive controller upgrades, offering significant benefits in applications such as protocol conversion, advanced control, data logging, and OEM machinery customization.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | IC693PCM311 |

| Product Type | Programmable Coprocessor Module |

| Compatible PLC | GE Fanuc Series 90-30 PLC |

| Processor Type | Intel 80C186 microprocessor |

| Operating Frequency | 12 MHz |

| Program Memory | 192 KB user-programmable Flash memory |

| Data Memory | 128 KB battery-backed SRAM |

| Serial Ports | 2 serial ports (COM1 & COM2) |

| Serial Interface Types | RS-232, RS-485 selectable |

| Serial Baud Rate | 300 bps to 38.4 kbps |

| Programming Languages | C, C++, BASIC |

| Communication Protocols | Modbus RTU, ASCII, custom protocols |

| Firmware Upgradable | Yes |

| Operating Temperature Range | 0°C to +60°C |

| Storage Temperature Range | -40°C to +85°C |

| Humidity Range | 5% to 95% non-condensing |

| Power Supply | 5 VDC from PLC backplane |

| Power Consumption | 500 mA @ 5 VDC |

| Dimensions (H x W x D) | 140 x 140 x 35 mm |

| Weight | 0.449 kg |

| Mounting Method | Installed in Series 90-30 PLC rack |

| Backplane Interface | High-speed data transfer |

| Diagnostic Features | LED indicators for module & port status |

| Certifications | UL, CSA, CE, RoHS |

Applications

-

Custom Control Routines: Execute advanced control functions that exceed PLC CPU capabilities.

-

Protocol Conversion: Interface with non-standard devices using Modbus RTU, ASCII, or user-defined protocols.

-

OEM Machine Integration: Enable machine builders to create unique control solutions embedded in their equipment.

-

Legacy Equipment Interface: Communicate with older devices and systems that use RS-232/RS-485.

-

Advanced Data Logging: Perform long-term data capture and formatting for process reporting or regulatory compliance.

-

SCADA Communication Gateway: Serve as a link between GE PLCs and SCADA or DCS systems.

-

Energy Monitoring: Collect, calculate, and report data from power monitoring equipment.

-

Batch Control: Manage recipe execution and batch control in process applications.

-

Barcode Integration: Interface with bar code scanners and printing equipment in manufacturing lines.

-

Event Processing: Handle time-sensitive and event-driven processes with minimal PLC CPU load.

Product Advantages

-

Offloads Processing: Frees the PLC CPU from complex tasks and lengthy routines.

-

Customizable: Supports industry-standard programming languages such as C, C++, and BASIC.

-

Independent Operation: Runs asynchronously to the PLC scan cycle for real-time performance.

-

Protocol Versatility: Bridges communication between PLCs and external devices using various serial protocols.

-

Serial Flexibility: Dual configurable ports (RS-232/RS-485) for broad hardware compatibility.

-

Easy Integration: Installs directly in the Series 90-30 rack without external wiring.

-

Expandable Functionality: Adds advanced logic, control, and communication features to legacy systems.

-

Industrial-grade Reliability: Built to withstand tough factory and plant environments.

-

Diagnostics: LED status indicators simplify troubleshooting and maintenance.

-

Cost-Effective: Extends PLC system life without requiring expensive hardware replacements.

Frequently Asked Questions (FAQ)

-

What is the GE IC693PCM311 used for?

It is a programmable coprocessor used to enhance the processing power of a Series 90-30 PLC system.

-

Can I run programs independently of the main PLC?

Yes, the PCM311 operates as an independent processor.

-

Which programming languages are supported?

The module supports C, C++, and BASIC programming.

-

What kind of devices can the serial ports connect to?

The dual ports can communicate with bar code readers, HMIs, printers, modems, sensors, drives, and legacy equipment.

-

Is the module firmware upgradable?

Yes, it supports firmware updates for added flexibility and improvements.

-

Does it support protocol conversion?

Yes, it can handle Modbus RTU, ASCII, and custom protocol conversion.

-

Can I log process data with this module?

Yes, it is ideal for advanced data logging applications.

-

What is the maximum baud rate supported by the serial ports?

The ports support up to 38.4 kbps.

-

Is the module compatible with SCADA systems?

Yes, it is often used as a communication gateway to SCADA or DCS platforms.

-

What industries commonly use the IC693PCM311?

Industries include manufacturing, utilities, process industries, energy, OEM equipment, and transportation.

General Electric IC693PCM311 Programmable Coprocessor Module

Manufacturer:GE

Product Number:IC693PCM311

Product Type:Programmable Coprocessor Module

Origin:USA

Dimensions:140 x 140 x 35 mm

Weight:0.449 kg

Views:32

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IC693PCM311 Programmable Coprocessor Module (PCM) is a high-performance coprocessor specifically designed to expand the capabilities of the GE Fanuc Series 90-30 PLC system. It operates as an independent processing unit within the PLC rack, capable of executing complex algorithms, handling advanced communications, and managing demanding data processing tasks that would otherwise burden the main PLC CPU.

Built around a fast Intel 80C186 processor, the IC693PCM311 is engineered to allow users to develop and deploy custom programs using C, C++, or BASIC. It supports two serial ports (RS-232/RS-485), making it ideal for communicating with a wide variety of external devices—including drives, sensors, printers, bar code readers, HMIs, and legacy equipment.

This flexible module allows plant operators and system integrators to extend the functionality of their Series 90-30 PLC without needing expensive controller upgrades, offering significant benefits in applications such as protocol conversion, advanced control, data logging, and OEM machinery customization.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | IC693PCM311 |

| Product Type | Programmable Coprocessor Module |

| Compatible PLC | GE Fanuc Series 90-30 PLC |

| Processor Type | Intel 80C186 microprocessor |

| Operating Frequency | 12 MHz |

| Program Memory | 192 KB user-programmable Flash memory |

| Data Memory | 128 KB battery-backed SRAM |

| Serial Ports | 2 serial ports (COM1 & COM2) |

| Serial Interface Types | RS-232, RS-485 selectable |

| Serial Baud Rate | 300 bps to 38.4 kbps |

| Programming Languages | C, C++, BASIC |

| Communication Protocols | Modbus RTU, ASCII, custom protocols |

| Firmware Upgradable | Yes |

| Operating Temperature Range | 0°C to +60°C |

| Storage Temperature Range | -40°C to +85°C |

| Humidity Range | 5% to 95% non-condensing |

| Power Supply | 5 VDC from PLC backplane |

| Power Consumption | 500 mA @ 5 VDC |

| Dimensions (H x W x D) | 140 x 140 x 35 mm |

| Weight | 0.449 kg |

| Mounting Method | Installed in Series 90-30 PLC rack |

| Backplane Interface | High-speed data transfer |

| Diagnostic Features | LED indicators for module & port status |

| Certifications | UL, CSA, CE, RoHS |

Applications

-

Custom Control Routines: Execute advanced control functions that exceed PLC CPU capabilities.

-

Protocol Conversion: Interface with non-standard devices using Modbus RTU, ASCII, or user-defined protocols.

-

OEM Machine Integration: Enable machine builders to create unique control solutions embedded in their equipment.

-

Legacy Equipment Interface: Communicate with older devices and systems that use RS-232/RS-485.

-

Advanced Data Logging: Perform long-term data capture and formatting for process reporting or regulatory compliance.

-

SCADA Communication Gateway: Serve as a link between GE PLCs and SCADA or DCS systems.

-

Energy Monitoring: Collect, calculate, and report data from power monitoring equipment.

-

Batch Control: Manage recipe execution and batch control in process applications.

-

Barcode Integration: Interface with bar code scanners and printing equipment in manufacturing lines.

-

Event Processing: Handle time-sensitive and event-driven processes with minimal PLC CPU load.

Product Advantages

-

Offloads Processing: Frees the PLC CPU from complex tasks and lengthy routines.

-

Customizable: Supports industry-standard programming languages such as C, C++, and BASIC.

-

Independent Operation: Runs asynchronously to the PLC scan cycle for real-time performance.

-

Protocol Versatility: Bridges communication between PLCs and external devices using various serial protocols.

-

Serial Flexibility: Dual configurable ports (RS-232/RS-485) for broad hardware compatibility.

-

Easy Integration: Installs directly in the Series 90-30 rack without external wiring.

-

Expandable Functionality: Adds advanced logic, control, and communication features to legacy systems.

-

Industrial-grade Reliability: Built to withstand tough factory and plant environments.

-

Diagnostics: LED status indicators simplify troubleshooting and maintenance.

-

Cost-Effective: Extends PLC system life without requiring expensive hardware replacements.

Frequently Asked Questions (FAQ)

-

What is the GE IC693PCM311 used for?

It is a programmable coprocessor used to enhance the processing power of a Series 90-30 PLC system.

-

Can I run programs independently of the main PLC?

Yes, the PCM311 operates as an independent processor.

-

Which programming languages are supported?

The module supports C, C++, and BASIC programming.

-

What kind of devices can the serial ports connect to?

The dual ports can communicate with bar code readers, HMIs, printers, modems, sensors, drives, and legacy equipment.

-

Is the module firmware upgradable?

Yes, it supports firmware updates for added flexibility and improvements.

-

Does it support protocol conversion?

Yes, it can handle Modbus RTU, ASCII, and custom protocol conversion.

-

Can I log process data with this module?

Yes, it is ideal for advanced data logging applications.

-

What is the maximum baud rate supported by the serial ports?

The ports support up to 38.4 kbps.

-

Is the module compatible with SCADA systems?

Yes, it is often used as a communication gateway to SCADA or DCS platforms.

-

What industries commonly use the IC693PCM311?

Industries include manufacturing, utilities, process industries, energy, OEM equipment, and transportation.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...