Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

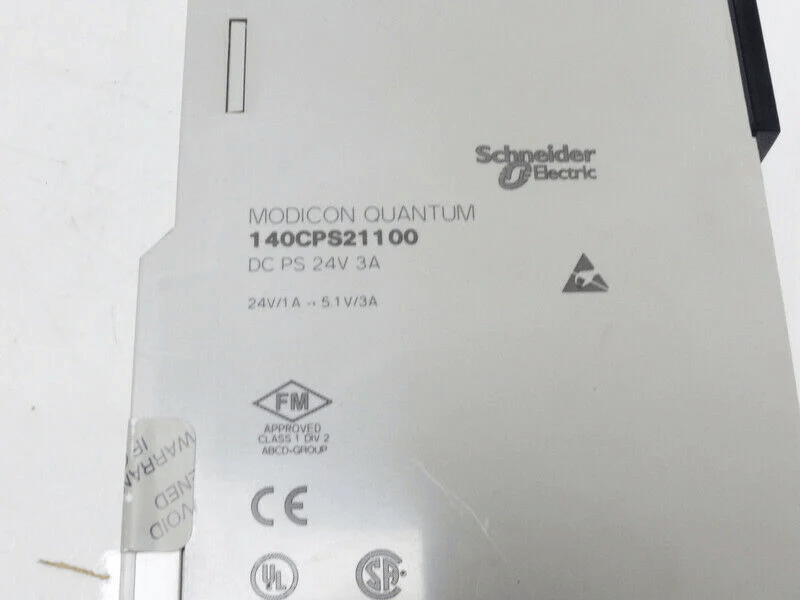

Schneider 140CHS21000 Hot Standby kit

Manufacturer:Schneider

Product Number:140CHS21000

Product Type:Hot Standby kit

Origin:France

Dimensions:103.9 × 40.3 × 250

Weight:2.54 kg

Views:46

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Schneider 140CHS21000 Hot Standby Kit is a high-availability automation component designed for the Modicon Quantum series of PLCs. This kit enables a dual-CPU architecture, allowing one CPU to act as the active processor and another to serve as a fully synchronized backup (hot standby), ready to take over instantly in the event of a primary failure.

This seamless redundancy ensures continuous operation for critical applications in process automation, manufacturing control, energy management, and infrastructure systems. With rapid switchover (typically within milliseconds), the kit dramatically reduces system downtime and minimizes the risk of production losses or safety incidents.

The 140CHS21000 Hot Standby Kit is compatible with various Quantum CPU models and is widely adopted in industries where system availability and process continuity are paramount.

Product Specifications

| Parameter | Value |

|---|---|

| Model | 140CHS21000 |

| Product Type | Hot Standby Kit |

| Compatible Series | Modicon Quantum |

| Compatibility | All Quantum CPU supporting Hot Standby |

| Communication Ports | 2 x RJ45 Ethernet ports |

| Synchronization Method | Fiber optic / Ethernet-based (depending on CPU) |

| Supported Redundancy | CPU redundancy (Hot Standby) |

| Switchover Time | < 50 ms typical |

| Redundancy Synchronization Rate | Up to 100 Mbps |

| Supported CPU Firmware Versions | V3.0 and above |

| Operating Voltage Range | 24 VDC |

| Power Consumption | < 5 W |

| Operating Temperature | 0 °C to +60 °C |

| Storage Temperature | -25 °C to +70 °C |

| Relative Humidity (Non-condensing) | 5% to 95% RH |

| Mounting | DIN-rail or panel mounting |

| EMC Compliance | IEC 61131-2, CE |

| UL, CSA Certification | Yes |

| Dimensions (W × H × D) | 103.9 × 40.3 × 250 |

| Weight | 2.54 kg |

| Housing Material | Industrial-grade metal with protective coating |

| Mean Time Between Failures (MTBF) | > 400,000 hours |

Applications

The Schneider 140CHS21000 Hot Standby Kit is widely used in applications requiring zero downtime and high operational reliability, such as:

-

Process Industries

Chemical, petrochemical, and pharmaceutical plants with continuous processes.

-

Water & Wastewater Treatment

Ensuring non-stop operation of critical pumping, filtration, and control systems.

-

Power Generation & Distribution

Automation of turbines, substations, and energy storage systems.

-

Food & Beverage Manufacturing

Where process interruption can lead to large-scale product loss or contamination.

-

Oil & Gas Sector

Onshore and offshore production, refining, and pipeline operations.

-

Transportation Infrastructure

Airport systems, railway networks, and intelligent traffic control.

-

Metals & Mining

Redundant control of extraction, smelting, and conveyor systems.

Product Advantages

-

High Availability

Provides seamless CPU redundancy, ensuring critical process continuity.

-

Fast Switchover

Typically switches to backup CPU in under 50 ms, minimizing disruptions.

-

Full Synchronization

Automatically synchronizes all CPU memory and I/O states between active and standby processors.

-

Proven Compatibility

Designed specifically for Quantum series PLCs, ensuring simple integration.

-

Compact Design

Minimal panel space required, thanks to optimized module size.

-

Easy to Implement

Supported by Unity Pro / EcoStruxure Control Expert programming software.

-

Industrial-grade Reliability

Operates continuously in harsh environments with high MTBF.

-

Certified & Compliant

Meets international standards for industrial automation systems (CE, UL, CSA).

-

Field-proven Performance

Installed in thousands of mission-critical applications worldwide.

-

Minimal Maintenance

Simple diagnostics and long service life reduce lifecycle costs.

Frequently Asked Questions (FAQ)

-

What is the main function of the 140CHS21000 Hot Standby Kit?

It enables a hot standby redundant CPU architecture to ensure continuous operation in case of CPU failure.

-

Which PLC series does it support?

The kit is specifically designed for the Modicon Quantum series of PLCs.

-

How fast is the switchover?

Typical switchover occurs in less than 50 ms, depending on application conditions.

-

Does the kit require special cabling?

It supports both fiber optic and Ethernet-based synchronization, depending on the CPU.

-

Can the system detect a fault automatically?

Yes, built-in diagnostics automatically monitor CPU health and trigger a switchover if needed.

-

Does it require additional software licenses?

No special license is required, only a supported version of Unity Pro or EcoStruxure Control Expert.

-

Is there a limit to the distance between CPUs?

For Ethernet synchronization, standard industrial Ethernet distances apply; for fiber optic, distances up to several kilometers are supported.

-

Can I use this kit in outdoor or harsh environments?

Yes, it is designed to withstand industrial temperature and humidity ranges.

-

Is redundancy limited to the CPU?

This kit enables CPU redundancy; separate I/O redundancy or power redundancy may require additional components.

-

What is the expected service life of the 140CHS21000?

The module offers MTBF of over 400,000 hours, ensuring many years of operation.

Schneider 140CHS21000 Hot Standby kit

Manufacturer:Schneider

Product Number:140CHS21000

Product Type:Hot Standby kit

Origin:France

Dimensions:103.9 × 40.3 × 250

Weight:2.54 kg

Views:46

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Schneider 140CHS21000 Hot Standby Kit is a high-availability automation component designed for the Modicon Quantum series of PLCs. This kit enables a dual-CPU architecture, allowing one CPU to act as the active processor and another to serve as a fully synchronized backup (hot standby), ready to take over instantly in the event of a primary failure.

This seamless redundancy ensures continuous operation for critical applications in process automation, manufacturing control, energy management, and infrastructure systems. With rapid switchover (typically within milliseconds), the kit dramatically reduces system downtime and minimizes the risk of production losses or safety incidents.

The 140CHS21000 Hot Standby Kit is compatible with various Quantum CPU models and is widely adopted in industries where system availability and process continuity are paramount.

Product Specifications

| Parameter | Value |

|---|---|

| Model | 140CHS21000 |

| Product Type | Hot Standby Kit |

| Compatible Series | Modicon Quantum |

| Compatibility | All Quantum CPU supporting Hot Standby |

| Communication Ports | 2 x RJ45 Ethernet ports |

| Synchronization Method | Fiber optic / Ethernet-based (depending on CPU) |

| Supported Redundancy | CPU redundancy (Hot Standby) |

| Switchover Time | < 50 ms typical |

| Redundancy Synchronization Rate | Up to 100 Mbps |

| Supported CPU Firmware Versions | V3.0 and above |

| Operating Voltage Range | 24 VDC |

| Power Consumption | < 5 W |

| Operating Temperature | 0 °C to +60 °C |

| Storage Temperature | -25 °C to +70 °C |

| Relative Humidity (Non-condensing) | 5% to 95% RH |

| Mounting | DIN-rail or panel mounting |

| EMC Compliance | IEC 61131-2, CE |

| UL, CSA Certification | Yes |

| Dimensions (W × H × D) | 103.9 × 40.3 × 250 |

| Weight | 2.54 kg |

| Housing Material | Industrial-grade metal with protective coating |

| Mean Time Between Failures (MTBF) | > 400,000 hours |

Applications

The Schneider 140CHS21000 Hot Standby Kit is widely used in applications requiring zero downtime and high operational reliability, such as:

-

Process Industries

Chemical, petrochemical, and pharmaceutical plants with continuous processes.

-

Water & Wastewater Treatment

Ensuring non-stop operation of critical pumping, filtration, and control systems.

-

Power Generation & Distribution

Automation of turbines, substations, and energy storage systems.

-

Food & Beverage Manufacturing

Where process interruption can lead to large-scale product loss or contamination.

-

Oil & Gas Sector

Onshore and offshore production, refining, and pipeline operations.

-

Transportation Infrastructure

Airport systems, railway networks, and intelligent traffic control.

-

Metals & Mining

Redundant control of extraction, smelting, and conveyor systems.

Product Advantages

-

High Availability

Provides seamless CPU redundancy, ensuring critical process continuity.

-

Fast Switchover

Typically switches to backup CPU in under 50 ms, minimizing disruptions.

-

Full Synchronization

Automatically synchronizes all CPU memory and I/O states between active and standby processors.

-

Proven Compatibility

Designed specifically for Quantum series PLCs, ensuring simple integration.

-

Compact Design

Minimal panel space required, thanks to optimized module size.

-

Easy to Implement

Supported by Unity Pro / EcoStruxure Control Expert programming software.

-

Industrial-grade Reliability

Operates continuously in harsh environments with high MTBF.

-

Certified & Compliant

Meets international standards for industrial automation systems (CE, UL, CSA).

-

Field-proven Performance

Installed in thousands of mission-critical applications worldwide.

-

Minimal Maintenance

Simple diagnostics and long service life reduce lifecycle costs.

Frequently Asked Questions (FAQ)

-

What is the main function of the 140CHS21000 Hot Standby Kit?

It enables a hot standby redundant CPU architecture to ensure continuous operation in case of CPU failure.

-

Which PLC series does it support?

The kit is specifically designed for the Modicon Quantum series of PLCs.

-

How fast is the switchover?

Typical switchover occurs in less than 50 ms, depending on application conditions.

-

Does the kit require special cabling?

It supports both fiber optic and Ethernet-based synchronization, depending on the CPU.

-

Can the system detect a fault automatically?

Yes, built-in diagnostics automatically monitor CPU health and trigger a switchover if needed.

-

Does it require additional software licenses?

No special license is required, only a supported version of Unity Pro or EcoStruxure Control Expert.

-

Is there a limit to the distance between CPUs?

For Ethernet synchronization, standard industrial Ethernet distances apply; for fiber optic, distances up to several kilometers are supported.

-

Can I use this kit in outdoor or harsh environments?

Yes, it is designed to withstand industrial temperature and humidity ranges.

-

Is redundancy limited to the CPU?

This kit enables CPU redundancy; separate I/O redundancy or power redundancy may require additional components.

-

What is the expected service life of the 140CHS21000?

The module offers MTBF of over 400,000 hours, ensuring many years of operation.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...