Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

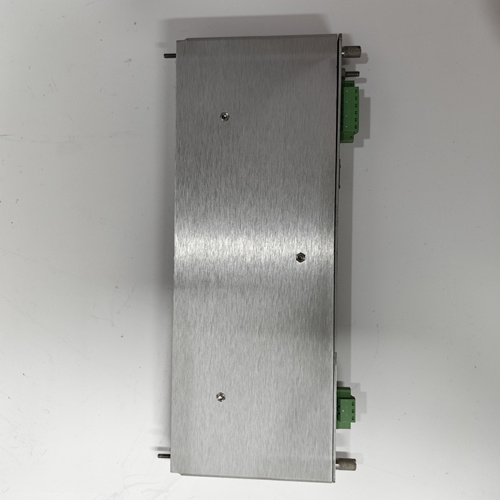

Bently Nevada 3300/47-09-03-01-00 Complementary Input Differential Expansion Monitor

Manufacturer:Bently Nevada

Product Number:3300/47-09-03-01-00

Product Type:Complementary Input Differential Expansion Monitor

Origin:USA

Vertical Dimension:83 mm

Weight:1 kg

Views:72

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3300/47-09-03-01-00 Complementary Input Differential Expansion Monitor is an essential component of the Bently Nevada 3300 series, designed to provide real-time monitoring and protection for industrial rotating machinery. This specialized module measures differential expansion in turbines and large-scale rotating equipment, detecting axial displacement caused by thermal expansion.

Equipped with high-precision proximity probes, the 3300/47-09-03-01-00 ensures accurate measurement of the relative movement between rotor and casing, preventing severe machinery damage due to thermal growth. Its robust design and seamless integration with Bently Nevada 3500 systems make it an industry-standard solution for condition monitoring in power plants, refineries, and heavy industrial applications.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | Bently Nevada 3300/47-09-03-01-00 |

| Series | 3300 Series |

| Measurement Type | Complementary Input Differential Expansion |

| Input Type | Dual-channel input signals |

| Compatible Sensors | Bently Nevada 3300 XL Proximity Probes |

| Output Signal | 4-20mA, Relay Output |

| Alarm Setpoints | Configurable for Warning and Danger Levels |

| Power Supply | 24V DC |

| Operating Temperature | -30°C to +85°C |

| Humidity Range | 5% to 95% Non-condensing |

| Communication Interface | Compatible with Bently Nevada 3500 System |

| Mounting Type | Rack-mounted in 3300 System |

| Vertical Dimension | 83 mm |

| Weight | 1 kg |

Applications

The Bently Nevada 3300/47-09-03-01-00 is designed for critical industrial applications where thermal expansion can significantly affect machinery performance. Key applications include:

- Steam Turbines – Monitoring rotor-to-casing expansion in power generation plants.

- Oil & Gas Compressors – Preventing damage due to differential thermal expansion.

- Petrochemical Equipment – Ensuring safe operation of large rotating machinery.

- Steel Processing Plants – Protecting against mechanical misalignment.

- Pulp & Paper Mills – Maintaining reliability in continuous production processes.

Product Advantages

- High-precision Measurement – Provides accurate real-time monitoring of differential expansion.

- Reliable Alarm System – Adjustable warning and danger thresholds for early fault detection.

- Seamless Integration – Fully compatible with Bently Nevada 3500 monitoring systems.

- Robust Design – Built to withstand harsh industrial environments.

- Reduced Downtime – Prevents unexpected machinery failures and costly repairs.

- User-friendly Configuration – Easy setup and integration into existing systems.

- Industry Standard Compliance – Meets global safety and reliability standards.

- Versatile Application – Suitable for a wide range of industrial machinery.

Bently Nevada 3300/47-09-03-01-00 Complementary Input Differential Expansion Monitor

Manufacturer:Bently Nevada

Product Number:3300/47-09-03-01-00

Product Type:Complementary Input Differential Expansion Monitor

Origin:USA

Vertical Dimension:83 mm

Weight:1 kg

Views:72

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3300/47-09-03-01-00 Complementary Input Differential Expansion Monitor is an essential component of the Bently Nevada 3300 series, designed to provide real-time monitoring and protection for industrial rotating machinery. This specialized module measures differential expansion in turbines and large-scale rotating equipment, detecting axial displacement caused by thermal expansion.

Equipped with high-precision proximity probes, the 3300/47-09-03-01-00 ensures accurate measurement of the relative movement between rotor and casing, preventing severe machinery damage due to thermal growth. Its robust design and seamless integration with Bently Nevada 3500 systems make it an industry-standard solution for condition monitoring in power plants, refineries, and heavy industrial applications.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | Bently Nevada 3300/47-09-03-01-00 |

| Series | 3300 Series |

| Measurement Type | Complementary Input Differential Expansion |

| Input Type | Dual-channel input signals |

| Compatible Sensors | Bently Nevada 3300 XL Proximity Probes |

| Output Signal | 4-20mA, Relay Output |

| Alarm Setpoints | Configurable for Warning and Danger Levels |

| Power Supply | 24V DC |

| Operating Temperature | -30°C to +85°C |

| Humidity Range | 5% to 95% Non-condensing |

| Communication Interface | Compatible with Bently Nevada 3500 System |

| Mounting Type | Rack-mounted in 3300 System |

| Vertical Dimension | 83 mm |

| Weight | 1 kg |

Applications

The Bently Nevada 3300/47-09-03-01-00 is designed for critical industrial applications where thermal expansion can significantly affect machinery performance. Key applications include:

- Steam Turbines – Monitoring rotor-to-casing expansion in power generation plants.

- Oil & Gas Compressors – Preventing damage due to differential thermal expansion.

- Petrochemical Equipment – Ensuring safe operation of large rotating machinery.

- Steel Processing Plants – Protecting against mechanical misalignment.

- Pulp & Paper Mills – Maintaining reliability in continuous production processes.

Product Advantages

- High-precision Measurement – Provides accurate real-time monitoring of differential expansion.

- Reliable Alarm System – Adjustable warning and danger thresholds for early fault detection.

- Seamless Integration – Fully compatible with Bently Nevada 3500 monitoring systems.

- Robust Design – Built to withstand harsh industrial environments.

- Reduced Downtime – Prevents unexpected machinery failures and costly repairs.

- User-friendly Configuration – Easy setup and integration into existing systems.

- Industry Standard Compliance – Meets global safety and reliability standards.

- Versatile Application – Suitable for a wide range of industrial machinery.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...