Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

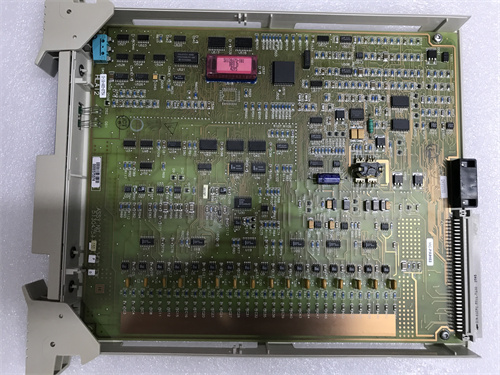

Honeywell 900CP1-0100 Control Processor Module

Manufacturer:Honeywell

Product Number:900CP1-0100

Product Type:Control Processor Module

Origin:USA

Dimensions:137 x 35.6 x 137.16 mm

Weight:0.18 kg

Views:50

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell 900CP1-0100 Control Processor Module is a central processing unit designed for the HC900 Hybrid Control System. It serves as the “brain” of the control rack, executing process control, sequencing, logic, and communication functions. Built with industrial-grade reliability, this processor module integrates seamlessly into the HC900 platform, delivering real-time monitoring, high-speed processing, and robust networking.

The 900CP1-0100 enables process industries to unify logic and loop control in one hardware module, eliminating the need for separate PLC and DCS systems. It provides an optimal solution for mid-range automation, balancing flexibility, power, and redundancy.

Product Specifications

| Parameter | Description |

|---|---|

| Model | Honeywell 900CP1-0100 |

| Product Type | Control Processor Module (HC900 series) |

| Processor Type | 32-bit high-performance CPU |

| Memory | 32 MB RAM, 16 MB Flash for program and data storage |

| I/O Capacity | Up to 4,000 I/O points with modular expansion |

| Communication Interfaces | Ethernet (Modbus TCP/IP), peer-to-peer networking, backplane bus |

| Redundancy | Supports controller redundancy with paired modules |

| Scan Rate | As low as 10 ms depending on system load |

| Power Supply Requirement | 24 V DC nominal (18–32 V DC range) |

| Operating Temperature | 0–60 °C |

| Storage Temperature | -20–70 °C |

| Humidity Range | 5–95% RH, non-condensing |

| Standards Compliance | CE, UL, CSA, IEC/EN 61131 |

| Diagnostics | Built-in watchdog, self-check, fault LEDs |

| Dimensions | 137 x 35.6 x 137.16 mm |

| Weight | 0.18 kg |

Product Applications

The 900CP1-0100 Control Processor Module is widely deployed across diverse industries due to its ability to combine process automation and logic control. Key applications include:

-

Power Generation – Boiler control, turbine auxiliary systems, and safety interlocks.

-

Oil & Gas / Petrochemical – Reactor control, compressor monitoring, and process sequencing.

-

Water and Wastewater Treatment – Pump control, dosing systems, filtration, and plant automation.

-

Food & Beverage – Batch processing, recipe management, and temperature control.

-

Pharmaceutical Industry – Sterilization, clean room automation, and regulatory compliance control.

-

Metals and Mining – Furnace control, rolling mill automation, and safety systems.

Product Advantages

-

Unified Control – Combines loop, logic, and sequencing in one processor.

-

High-Speed Performance – Fast execution cycle enables precise process control.

-

Redundancy Support – Works in paired configuration for fault-tolerant operation.

-

Scalability – Supports expansion up to thousands of I/O points.

-

Seamless Integration – Compatible with Honeywell Experion® and third-party SCADA systems.

-

Diagnostics and Reliability – Built-in fault detection and watchdog timer.

-

Industrial-Grade Design – Rugged module suitable for continuous 24/7 operation.

-

Flexible Networking – Supports Ethernet communication and Modbus TCP/IP protocols.

FAQ

-

What type of CPU architecture does the 900CP1-0100 use?

It uses a 32-bit high-performance CPU optimized for real-time process control.

-

Does this module support controller redundancy?

Yes, it can be paired with another 900CP1-0100 for redundant operation.

-

What is the maximum number of I/O points supported?

Up to 4,000 I/O points can be configured with modular expansion.

-

How fast is the scan cycle of the processor?

The processor can achieve a scan rate as low as 10 ms depending on system configuration.

-

Which communication protocols are supported?

It supports Ethernet, Modbus TCP/IP, peer-to-peer networking, and the backplane bus.

-

Can this module be integrated with Honeywell Experion systems?

Yes, it is fully compatible with Experion® PKS for extended control and monitoring.

-

What diagnostic features are included?

The module has self-check mechanisms, watchdog timers, and fault indication LEDs.

-

Is it possible to hot-swap this processor module?

No, the processor itself is not hot-swappable, but certain I/O modules are.

-

How is memory allocated for user programs?

It includes 32 MB RAM and 16 MB Flash for programs, historical data, and process variables.

-

What redundancy modes are supported?

It supports CPU redundancy, automatic switchover, and communication failover.

Honeywell 900CP1-0100 Control Processor Module

Manufacturer:Honeywell

Product Number:900CP1-0100

Product Type:Control Processor Module

Origin:USA

Dimensions:137 x 35.6 x 137.16 mm

Weight:0.18 kg

Views:50

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell 900CP1-0100 Control Processor Module is a central processing unit designed for the HC900 Hybrid Control System. It serves as the “brain” of the control rack, executing process control, sequencing, logic, and communication functions. Built with industrial-grade reliability, this processor module integrates seamlessly into the HC900 platform, delivering real-time monitoring, high-speed processing, and robust networking.

The 900CP1-0100 enables process industries to unify logic and loop control in one hardware module, eliminating the need for separate PLC and DCS systems. It provides an optimal solution for mid-range automation, balancing flexibility, power, and redundancy.

Product Specifications

| Parameter | Description |

|---|---|

| Model | Honeywell 900CP1-0100 |

| Product Type | Control Processor Module (HC900 series) |

| Processor Type | 32-bit high-performance CPU |

| Memory | 32 MB RAM, 16 MB Flash for program and data storage |

| I/O Capacity | Up to 4,000 I/O points with modular expansion |

| Communication Interfaces | Ethernet (Modbus TCP/IP), peer-to-peer networking, backplane bus |

| Redundancy | Supports controller redundancy with paired modules |

| Scan Rate | As low as 10 ms depending on system load |

| Power Supply Requirement | 24 V DC nominal (18–32 V DC range) |

| Operating Temperature | 0–60 °C |

| Storage Temperature | -20–70 °C |

| Humidity Range | 5–95% RH, non-condensing |

| Standards Compliance | CE, UL, CSA, IEC/EN 61131 |

| Diagnostics | Built-in watchdog, self-check, fault LEDs |

| Dimensions | 137 x 35.6 x 137.16 mm |

| Weight | 0.18 kg |

Product Applications

The 900CP1-0100 Control Processor Module is widely deployed across diverse industries due to its ability to combine process automation and logic control. Key applications include:

-

Power Generation – Boiler control, turbine auxiliary systems, and safety interlocks.

-

Oil & Gas / Petrochemical – Reactor control, compressor monitoring, and process sequencing.

-

Water and Wastewater Treatment – Pump control, dosing systems, filtration, and plant automation.

-

Food & Beverage – Batch processing, recipe management, and temperature control.

-

Pharmaceutical Industry – Sterilization, clean room automation, and regulatory compliance control.

-

Metals and Mining – Furnace control, rolling mill automation, and safety systems.

Product Advantages

-

Unified Control – Combines loop, logic, and sequencing in one processor.

-

High-Speed Performance – Fast execution cycle enables precise process control.

-

Redundancy Support – Works in paired configuration for fault-tolerant operation.

-

Scalability – Supports expansion up to thousands of I/O points.

-

Seamless Integration – Compatible with Honeywell Experion® and third-party SCADA systems.

-

Diagnostics and Reliability – Built-in fault detection and watchdog timer.

-

Industrial-Grade Design – Rugged module suitable for continuous 24/7 operation.

-

Flexible Networking – Supports Ethernet communication and Modbus TCP/IP protocols.

FAQ

-

What type of CPU architecture does the 900CP1-0100 use?

It uses a 32-bit high-performance CPU optimized for real-time process control.

-

Does this module support controller redundancy?

Yes, it can be paired with another 900CP1-0100 for redundant operation.

-

What is the maximum number of I/O points supported?

Up to 4,000 I/O points can be configured with modular expansion.

-

How fast is the scan cycle of the processor?

The processor can achieve a scan rate as low as 10 ms depending on system configuration.

-

Which communication protocols are supported?

It supports Ethernet, Modbus TCP/IP, peer-to-peer networking, and the backplane bus.

-

Can this module be integrated with Honeywell Experion systems?

Yes, it is fully compatible with Experion® PKS for extended control and monitoring.

-

What diagnostic features are included?

The module has self-check mechanisms, watchdog timers, and fault indication LEDs.

-

Is it possible to hot-swap this processor module?

No, the processor itself is not hot-swappable, but certain I/O modules are.

-

How is memory allocated for user programs?

It includes 32 MB RAM and 16 MB Flash for programs, historical data, and process variables.

-

What redundancy modes are supported?

It supports CPU redundancy, automatic switchover, and communication failover.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...