Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

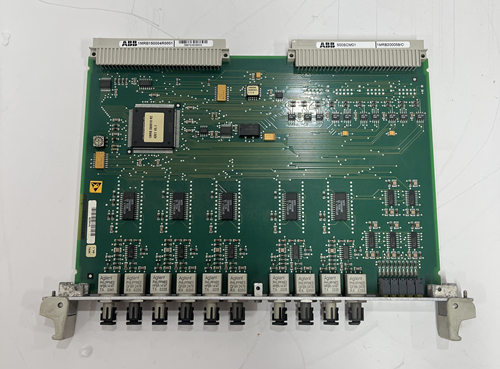

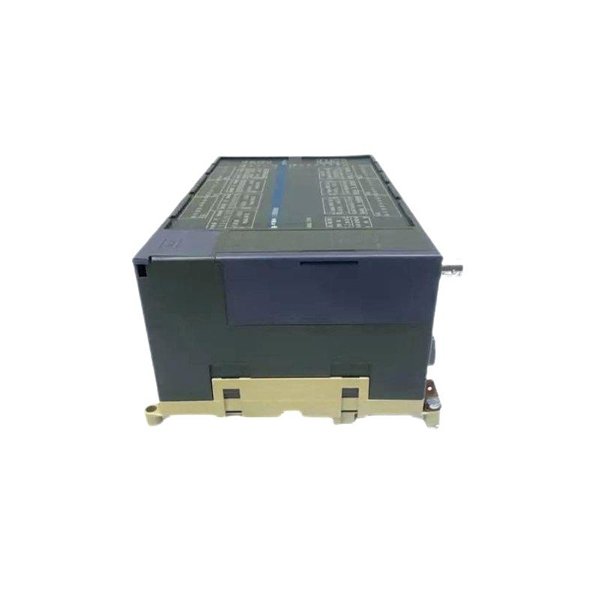

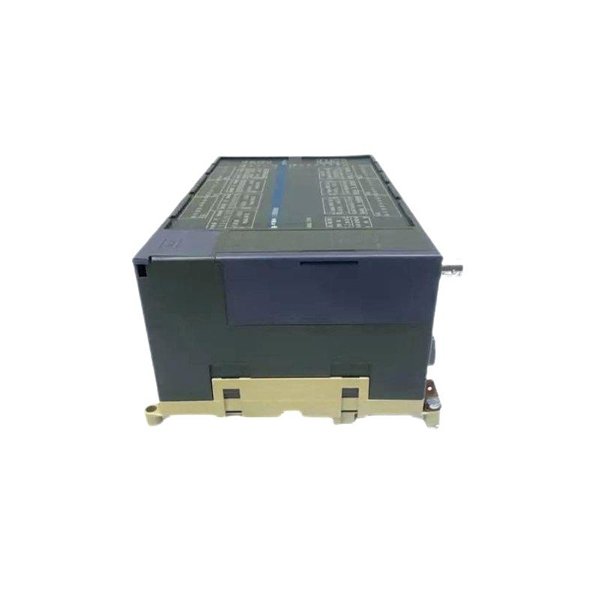

ABB 07KT94/07KT94k GJR5252100R3161 Controller

Manufacturer:ABB

Product Number:07KT94/07KT94k GJR5252100R3161

Product Type:Controller

Origin:Sweden

Dimensions:240 x 140 x 85 mm

Weight:1.6 kg

Views:59

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

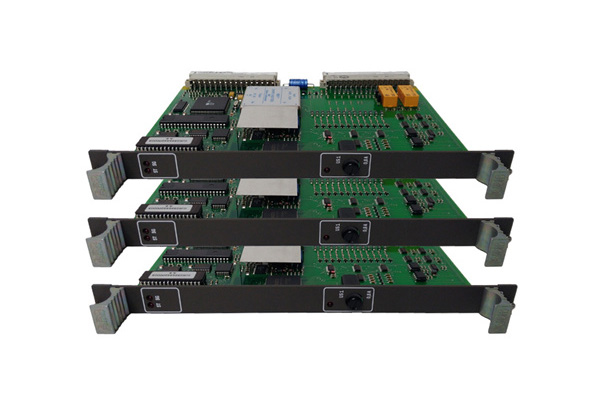

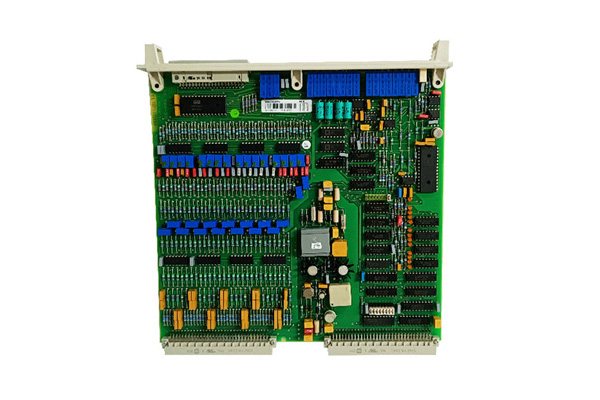

The ABB 07KT94/07KT94k GJR5252100R3161 is a sophisticated and highly reliable industrial automation controller designed for demanding process control environments. As part of ABB’s renowned Advant Controller family, this unit plays a critical role in distributed control systems (DCS), particularly within the ABB Advant Master system architecture. It is used extensively across a variety of industries where stable, continuous, and high-integrity process control is required.

This model features modular flexibility, real-time operation capabilities, and full integration with I/O systems and fieldbus communication protocols. With decades of field-tested performance, the 07KT94/07KT94k GJR5252100R3161 is a preferred choice for upgrading legacy control systems or implementing dependable process control in greenfield projects. It supports various communication interfaces and is known for its hot-swappable capability, minimal downtime during maintenance, and excellent fault-tolerance.

Product Specifications

| Parameter | Details |

|---|---|

| Product Name | ABB 07KT94 / 07KT94k GJR5252100R3161 Controller |

| Type | Industrial Automation Controller (Advant Controller 31 Series) |

| Processor Type | 32-bit Microprocessor |

| Power Supply | 24 V DC (±20%) |

| Memory | Integrated memory for real-time process control |

| Mounting Type | DIN Rail or Rack-mounted (modular system) |

| Input/Output Capacity | Up to 512 I/O points (via extension modules) |

| Supported Protocols | PROFIBUS, MODBUS, MasterBus 300, CS31 Bus |

| Redundancy | Supports CPU and communication redundancy |

| Diagnostics | Advanced self-diagnostics with LED status indicators |

| Environmental Protection | IP20 |

| Operating Temperature | -10°C to +60°C |

| Storage Temperature | -25°C to +70°C |

| Humidity Tolerance | 5% to 95% non-condensing |

| Certifications | CE, UL, CSA, RoHS compliant |

| Dimensions (L x W x D) | 240 x 140 x 85 mm |

| Weight | 1.6 kg |

| Software Compatibility | Composer, Control Builder M, Advant Master DCS Software |

| Display/Interface | Optional LCD interface for diagnostics |

| Expansion Support | Compatible with multiple ABB expansion and I/O modules |

Applications

The ABB 07KT94/07KT94k GJR5252100R3161 Controller is engineered for use in mission-critical automation tasks where reliability, modularity, and efficient processing are vital. Typical application areas include:

-

Power Generation Plants: Used for boiler control, turbine monitoring, and grid integration.

-

Petrochemical & Refineries: Controls batch and continuous process systems, tank farms, and pumping stations.

-

Water and Wastewater Management: Controls filtration systems, chemical dosing units, and pump stations.

-

Pharmaceutical Industry: Ensures compliance with GMP and controls environmental and production parameters.

-

Pulp & Paper: Used for machine control, paper quality monitoring, and production line automation.

-

Steel and Metal Plants: Controls furnaces, rolling mills, and material handling systems.

Advantages

-

Modular and Scalable: Its modular construction allows for flexible scaling depending on the size of the control system, making it suitable for both small and large automation projects.

-

Enhanced Redundancy: Designed to offer redundancy in both CPU and communication channels, minimizing the risk of control failure.

-

Long Lifecycle Support: As part of ABB’s mature controller product line, it benefits from extensive lifecycle support, including spare parts and migration services.

-

Robust Industrial Design: Its ability to withstand wide temperature ranges and harsh environments ensures uninterrupted operation in industrial settings.

-

Low Maintenance: Features such as hot-swapping capability, self-diagnostics, and real-time alarms reduce downtime and simplify maintenance procedures.

-

Seamless Integration: The controller integrates easily with other ABB systems and third-party devices using standard industrial protocols.

-

Real-Time Control: Its high-speed processor ensures minimal latency, making it well-suited for real-time control systems.

-

Secure and Stable Operation: Designed for continuous operations, critical safety applications, and automation environments requiring uninterrupted uptime.

Frequently Asked Questions (FAQ)

-

What is the difference between 07KT94 and 07KT94k?

The “k” variant typically represents an updated hardware revision with minor performance or compatibility improvements.

-

Can this controller support redundant CPU configuration?

Yes, it supports hot-standby CPU redundancy for critical control applications.

-

Which I/O modules are compatible with this controller?

It is compatible with ABB S800 and S900 remote I/O systems, as well as legacy CS31-based I/O.

-

Is this controller compatible with modern HMI/SCADA software?

Yes, it communicates effectively with most HMI/SCADA platforms using standard protocols like MODBUS and PROFIBUS.

-

How is it typically programmed?

Programming is done using Control Builder or Advant Composer software, with support for standard IEC 61131-3 languages.

-

What is the typical lifespan of this controller in continuous operation?

With proper maintenance, the controller is expected to operate reliably for over 15 years.

-

Can this controller be used in hazardous environments?

It has an IP20 rating and is suitable for control rooms; hazardous area deployment requires enclosure-based protection.

-

Does the unit support firmware updates?

Yes, provides firmware upgrade tools compatible with maintenance systems.

-

What is the maximum I/O count this controller supports?

It supports up to 512 I/O points, scalable with additional modules.

-

Is remote monitoring possible with this unit?

Yes, remote diagnostics and control are supported when integrated with appropriate communication gateways.

ABB 07KT94/07KT94k GJR5252100R3161 Controller

Manufacturer:ABB

Product Number:07KT94/07KT94k GJR5252100R3161

Product Type:Controller

Origin:Sweden

Dimensions:240 x 140 x 85 mm

Weight:1.6 kg

Views:59

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB 07KT94/07KT94k GJR5252100R3161 is a sophisticated and highly reliable industrial automation controller designed for demanding process control environments. As part of ABB’s renowned Advant Controller family, this unit plays a critical role in distributed control systems (DCS), particularly within the ABB Advant Master system architecture. It is used extensively across a variety of industries where stable, continuous, and high-integrity process control is required.

This model features modular flexibility, real-time operation capabilities, and full integration with I/O systems and fieldbus communication protocols. With decades of field-tested performance, the 07KT94/07KT94k GJR5252100R3161 is a preferred choice for upgrading legacy control systems or implementing dependable process control in greenfield projects. It supports various communication interfaces and is known for its hot-swappable capability, minimal downtime during maintenance, and excellent fault-tolerance.

Product Specifications

| Parameter | Details |

|---|---|

| Product Name | ABB 07KT94 / 07KT94k GJR5252100R3161 Controller |

| Type | Industrial Automation Controller (Advant Controller 31 Series) |

| Processor Type | 32-bit Microprocessor |

| Power Supply | 24 V DC (±20%) |

| Memory | Integrated memory for real-time process control |

| Mounting Type | DIN Rail or Rack-mounted (modular system) |

| Input/Output Capacity | Up to 512 I/O points (via extension modules) |

| Supported Protocols | PROFIBUS, MODBUS, MasterBus 300, CS31 Bus |

| Redundancy | Supports CPU and communication redundancy |

| Diagnostics | Advanced self-diagnostics with LED status indicators |

| Environmental Protection | IP20 |

| Operating Temperature | -10°C to +60°C |

| Storage Temperature | -25°C to +70°C |

| Humidity Tolerance | 5% to 95% non-condensing |

| Certifications | CE, UL, CSA, RoHS compliant |

| Dimensions (L x W x D) | 240 x 140 x 85 mm |

| Weight | 1.6 kg |

| Software Compatibility | Composer, Control Builder M, Advant Master DCS Software |

| Display/Interface | Optional LCD interface for diagnostics |

| Expansion Support | Compatible with multiple ABB expansion and I/O modules |

Applications

The ABB 07KT94/07KT94k GJR5252100R3161 Controller is engineered for use in mission-critical automation tasks where reliability, modularity, and efficient processing are vital. Typical application areas include:

-

Power Generation Plants: Used for boiler control, turbine monitoring, and grid integration.

-

Petrochemical & Refineries: Controls batch and continuous process systems, tank farms, and pumping stations.

-

Water and Wastewater Management: Controls filtration systems, chemical dosing units, and pump stations.

-

Pharmaceutical Industry: Ensures compliance with GMP and controls environmental and production parameters.

-

Pulp & Paper: Used for machine control, paper quality monitoring, and production line automation.

-

Steel and Metal Plants: Controls furnaces, rolling mills, and material handling systems.

Advantages

-

Modular and Scalable: Its modular construction allows for flexible scaling depending on the size of the control system, making it suitable for both small and large automation projects.

-

Enhanced Redundancy: Designed to offer redundancy in both CPU and communication channels, minimizing the risk of control failure.

-

Long Lifecycle Support: As part of ABB’s mature controller product line, it benefits from extensive lifecycle support, including spare parts and migration services.

-

Robust Industrial Design: Its ability to withstand wide temperature ranges and harsh environments ensures uninterrupted operation in industrial settings.

-

Low Maintenance: Features such as hot-swapping capability, self-diagnostics, and real-time alarms reduce downtime and simplify maintenance procedures.

-

Seamless Integration: The controller integrates easily with other ABB systems and third-party devices using standard industrial protocols.

-

Real-Time Control: Its high-speed processor ensures minimal latency, making it well-suited for real-time control systems.

-

Secure and Stable Operation: Designed for continuous operations, critical safety applications, and automation environments requiring uninterrupted uptime.

Frequently Asked Questions (FAQ)

-

What is the difference between 07KT94 and 07KT94k?

The “k” variant typically represents an updated hardware revision with minor performance or compatibility improvements.

-

Can this controller support redundant CPU configuration?

Yes, it supports hot-standby CPU redundancy for critical control applications.

-

Which I/O modules are compatible with this controller?

It is compatible with ABB S800 and S900 remote I/O systems, as well as legacy CS31-based I/O.

-

Is this controller compatible with modern HMI/SCADA software?

Yes, it communicates effectively with most HMI/SCADA platforms using standard protocols like MODBUS and PROFIBUS.

-

How is it typically programmed?

Programming is done using Control Builder or Advant Composer software, with support for standard IEC 61131-3 languages.

-

What is the typical lifespan of this controller in continuous operation?

With proper maintenance, the controller is expected to operate reliably for over 15 years.

-

Can this controller be used in hazardous environments?

It has an IP20 rating and is suitable for control rooms; hazardous area deployment requires enclosure-based protection.

-

Does the unit support firmware updates?

Yes, provides firmware upgrade tools compatible with maintenance systems.

-

What is the maximum I/O count this controller supports?

It supports up to 512 I/O points, scalable with additional modules.

-

Is remote monitoring possible with this unit?

Yes, remote diagnostics and control are supported when integrated with appropriate communication gateways.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...