Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

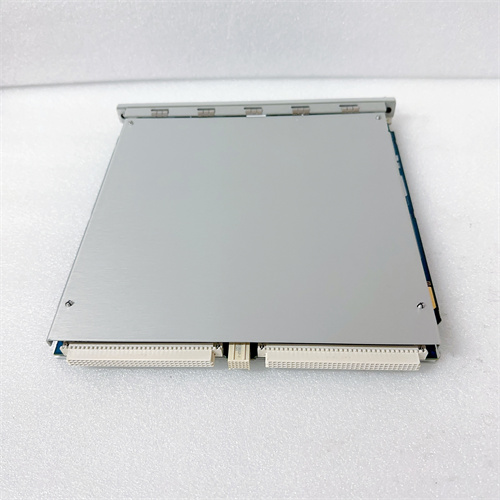

Bently Nevada 3300/20-03-01 Dual Thrust Monitor Board

Brand:Bently Nevada

Model Number:3300/20-03-01

Type:Dual Thrust Monitor Board

Product Origin:USA

Payment:T/T, Western Union, Credit Card

Dimensions:155 x 136 x 119 mm

Weight:280g

Price:USD87

Certificate:CE

Warranty:1 years

Product Description

The Bently Nevada 3300/20-03-01 is a Dual Thrust Monitor Board designed for advanced condition monitoring of rotating machinery. It specializes in measuring thrust bearing positions, ensuring accurate detection of potential issues.

Key Features

Dual Thrust Position Monitoring: Measures the positions of two thrust bearings in rotating machinery. This function helps identify misalignment, imbalance, and wear.

Data Acquisition: Collects data on parameters such as vibration, temperature, and pressure. Processes and analyzes this data to provide insights into machinery health.

Sensor Technology: Utilizes proximity probes to gauge the shaft’s position relative to the stationary housing. This technology ensures precise measurement.

Measurement Range: Accommodates various shaft diameters and operating conditions. Specific ranges may vary based on application needs.

Accuracy: Delivers high accuracy in shaft position measurement, crucial for detecting subtle changes that signal potential issues.

Data Output: Provides both analog and digital outputs. This flexibility allows integration with other monitoring or control systems.

Environmental Rating: Designed to endure harsh industrial environments, including extremes in vibration, temperature, and electromagnetic interference.

Applications

- Power Generation: Monitors turbines, generators, and pumps in power plants.

- Oil and Gas: Used for compressors, pumps, and rotating equipment in production facilities.

- Aerospace: Applies to aircraft engines and ground support machinery.

- Marine: Observes propulsion systems and auxiliary equipment on ships.

Benefits

Early Fault Detection: Identifies potential issues early, enabling timely maintenance and reducing the risk of unexpected failures.

Enhanced Reliability: Minimizes unplanned downtime, improving overall equipment reliability.

Optimized Maintenance: Supports condition-based maintenance, cutting costs and maximizing equipment uptime.

Bently Nevada 3300/20-03-01 Dual Thrust Monitor Board

Brand:Bently Nevada

Model Number:3300/20-03-01

Type:Dual Thrust Monitor Board

Product Origin:USA

Payment:T/T, Western Union, Credit Card

Dimensions:155 x 136 x 119 mm

Weight:280g

Price:USD87

Certificate:CE

Warranty:1 years

Product Description

The Bently Nevada 3300/20-03-01 is a Dual Thrust Monitor Board designed for advanced condition monitoring of rotating machinery. It specializes in measuring thrust bearing positions, ensuring accurate detection of potential issues.

Key Features

Dual Thrust Position Monitoring: Measures the positions of two thrust bearings in rotating machinery. This function helps identify misalignment, imbalance, and wear.

Data Acquisition: Collects data on parameters such as vibration, temperature, and pressure. Processes and analyzes this data to provide insights into machinery health.

Sensor Technology: Utilizes proximity probes to gauge the shaft’s position relative to the stationary housing. This technology ensures precise measurement.

Measurement Range: Accommodates various shaft diameters and operating conditions. Specific ranges may vary based on application needs.

Accuracy: Delivers high accuracy in shaft position measurement, crucial for detecting subtle changes that signal potential issues.

Data Output: Provides both analog and digital outputs. This flexibility allows integration with other monitoring or control systems.

Environmental Rating: Designed to endure harsh industrial environments, including extremes in vibration, temperature, and electromagnetic interference.

Applications

- Power Generation: Monitors turbines, generators, and pumps in power plants.

- Oil and Gas: Used for compressors, pumps, and rotating equipment in production facilities.

- Aerospace: Applies to aircraft engines and ground support machinery.

- Marine: Observes propulsion systems and auxiliary equipment on ships.

Benefits

Early Fault Detection: Identifies potential issues early, enabling timely maintenance and reducing the risk of unexpected failures.

Enhanced Reliability: Minimizes unplanned downtime, improving overall equipment reliability.

Optimized Maintenance: Supports condition-based maintenance, cutting costs and maximizing equipment uptime.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...