Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

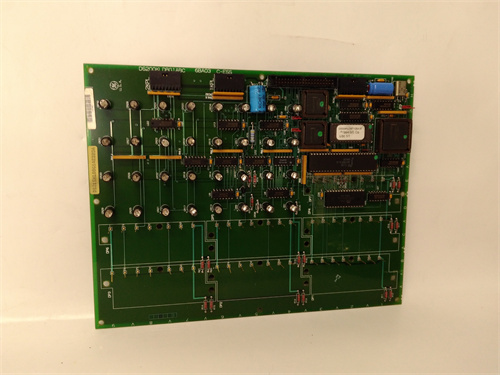

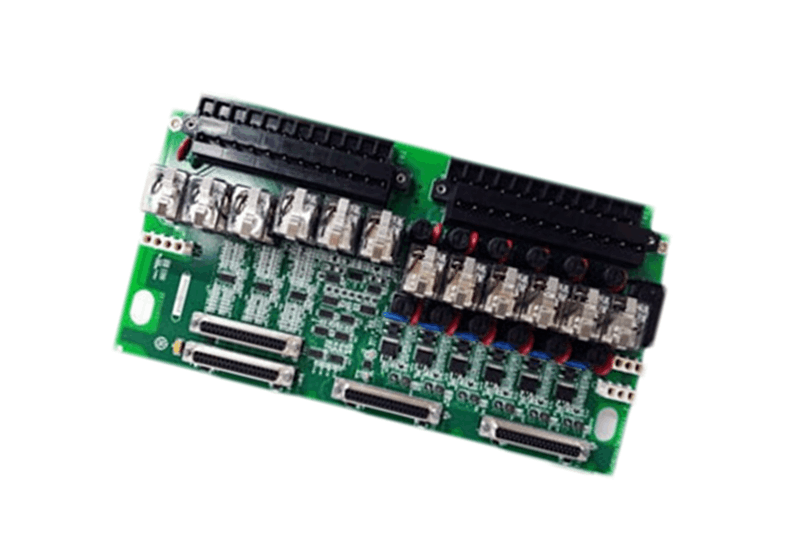

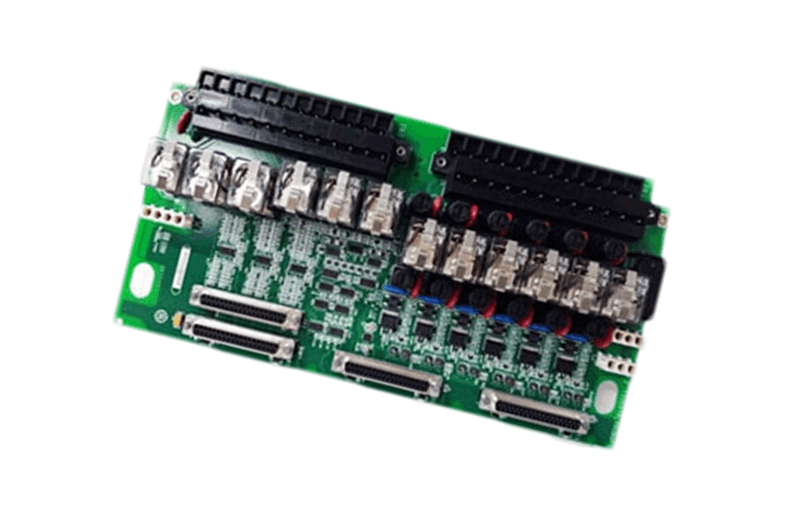

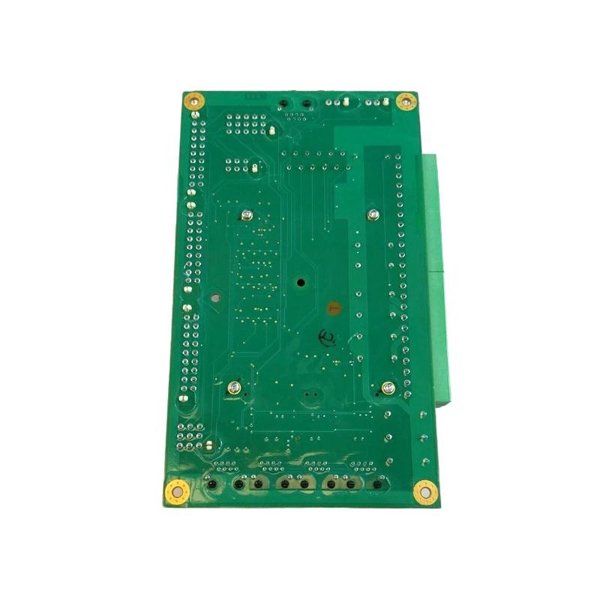

General Electric IS210BPPH2BLD Printed Circuit Board

Manufacturer:GE

Product Number:IS210BPPH2BLD

Product Type:Printed Circuit Board

Origin:USA

Dimensions:240 × 120 × 25 mm

Weight:1.25 kg

Views:16

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS210BPPH2BLD Printed Circuit Board (PCB) is a high-reliability control board engineered for GE’s Mark VIe turbine and industrial automation platforms. Designed to serve as a central interface for signal processing and power distribution, this board combines dense multilayer construction with advanced noise-suppression features. It provides stable operation in harsh industrial environments such as gas and steam turbine control rooms, power plants, and critical process facilities. Its robust layout and precision-engineered components ensure accurate data handling and long-term operational stability.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | IS210BPPH2BLD |

| Product Type | High-density printed circuit control board |

| Function | Signal conditioning, logic interfacing, and power routing |

| Series | GE Mark VIe Control System |

| Input Voltage Range | 24 V DC nominal (18–32 V DC operating window) |

| Output Interfaces | Multiple differential and single-ended I/O channels |

| Clock/Logic Speed | Up to 66 MHz embedded controller bus |

| Operating Temperature | –40 °C to +70 °C |

| Humidity Range | 0–95 % non-condensing |

| Vibration Resistance | Up to 5 g, 10–2000 Hz |

| Shock Resistance | 30 g, 11 ms half-sine |

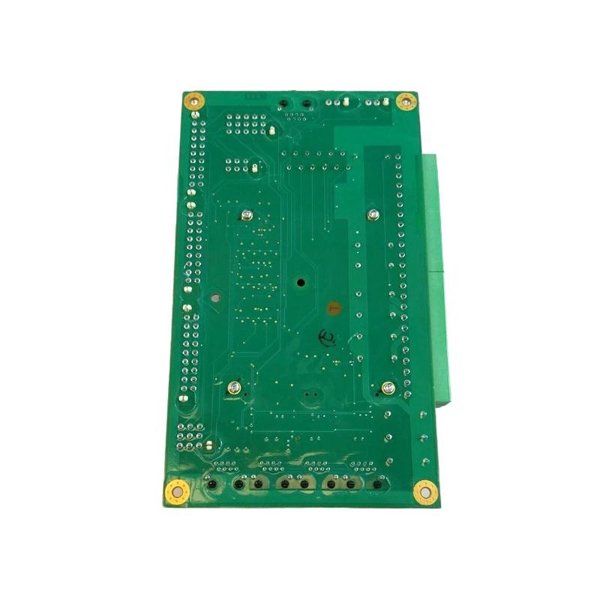

| PCB Layers | 8-layer FR4 with 2 oz copper and conformal coating |

| Diagnostics | On-board status LEDs and built-in self-test |

| Cooling | Natural convection or forced-air assisted |

| Dimensions (W×H×D) | 240 × 120 × 25 mm |

| Weight | 1.25 kg |

| Mounting | Rack or panel mounting with secure grounding |

| Compliance | RoHS, CE, UL recognized |

Applications

The IS210BPPH2BLD PCB is deployed in numerous industrial sectors:

-

Turbine Control Systems: Core logic interface for Mark VIe gas and steam turbine controllers.

-

Power Generation Plants: Manages I/O data flow and power routing to protection relays and sensors.

-

Industrial Automation: Provides precise signal conditioning for distributed control systems.

-

Oil & Gas Operations: Supports SCADA and compressor control modules in remote environments.

-

Process Manufacturing: Ensures stable instrumentation control in chemical, paper, and steel plants.

Advantages

-

High Signal Integrity: Eight-layer design with optimized ground planes minimizes electromagnetic interference.

-

Robust Protection: Built-in transient suppression and ESD safeguards protect downstream equipment.

-

Diagnostic Transparency: LED indicators and self-test firmware simplify maintenance and fault isolation.

-

Wide Environmental Tolerance: Reliable operation under extreme temperature, vibration, and humidity conditions.

-

Seamless Integration: Native compatibility with GE Mark VIe and other GE automation ecosystems.

-

Long Service Life: High-grade FR4 substrate and conformal coating extend operational longevity.

Frequently Asked Questions (FAQ)

-

What type of bus communication is supported by the IS210BPPH2BLD?

It supports a high-speed internal backplane bus compatible with Mark VIe system architecture.

-

How is signal integrity maintained across the multilayer board?

Ground and power planes are strategically placed to reduce crosstalk and maintain low impedance paths.

-

Does the board provide galvanic isolation between I/O sections?

Yes, opto-isolators are used for critical I/O channels to prevent ground loops.

-

What diagnostic protocols are available for remote monitoring?

It supports Mark VIe diagnostic communications and Modbus/TCP for supervisory systems.

-

How does the board handle power surges or transient spikes?

Integrated TVS diodes and surge suppressors protect sensitive circuitry.

-

Is there onboard firmware for self-testing?

Yes, embedded firmware runs power-on self-tests and reports status to the control processor.

-

What is the maximum supported data throughput?

Up to 66 MHz logic bus frequency, supporting high-speed real-time control loops.

-

Can the board be hot-swapped in a live system?

It can be hot-inserted if the backplane segment is properly de-energized and configured for redundancy.

-

What grounding scheme is recommended for installation?

A single-point earth ground with low impedance is recommended to minimize noise.

-

How is thermal management ensured without active cooling?

Large copper planes and strategic component placement enable efficient heat dissipation under natural convection.

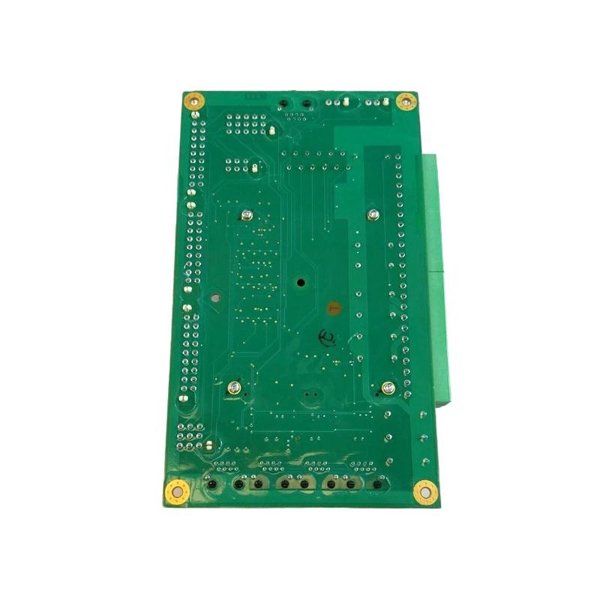

General Electric IS210BPPH2BLD Printed Circuit Board

Manufacturer:GE

Product Number:IS210BPPH2BLD

Product Type:Printed Circuit Board

Origin:USA

Dimensions:240 × 120 × 25 mm

Weight:1.25 kg

Views:16

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS210BPPH2BLD Printed Circuit Board (PCB) is a high-reliability control board engineered for GE’s Mark VIe turbine and industrial automation platforms. Designed to serve as a central interface for signal processing and power distribution, this board combines dense multilayer construction with advanced noise-suppression features. It provides stable operation in harsh industrial environments such as gas and steam turbine control rooms, power plants, and critical process facilities. Its robust layout and precision-engineered components ensure accurate data handling and long-term operational stability.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | IS210BPPH2BLD |

| Product Type | High-density printed circuit control board |

| Function | Signal conditioning, logic interfacing, and power routing |

| Series | GE Mark VIe Control System |

| Input Voltage Range | 24 V DC nominal (18–32 V DC operating window) |

| Output Interfaces | Multiple differential and single-ended I/O channels |

| Clock/Logic Speed | Up to 66 MHz embedded controller bus |

| Operating Temperature | –40 °C to +70 °C |

| Humidity Range | 0–95 % non-condensing |

| Vibration Resistance | Up to 5 g, 10–2000 Hz |

| Shock Resistance | 30 g, 11 ms half-sine |

| PCB Layers | 8-layer FR4 with 2 oz copper and conformal coating |

| Diagnostics | On-board status LEDs and built-in self-test |

| Cooling | Natural convection or forced-air assisted |

| Dimensions (W×H×D) | 240 × 120 × 25 mm |

| Weight | 1.25 kg |

| Mounting | Rack or panel mounting with secure grounding |

| Compliance | RoHS, CE, UL recognized |

Applications

The IS210BPPH2BLD PCB is deployed in numerous industrial sectors:

-

Turbine Control Systems: Core logic interface for Mark VIe gas and steam turbine controllers.

-

Power Generation Plants: Manages I/O data flow and power routing to protection relays and sensors.

-

Industrial Automation: Provides precise signal conditioning for distributed control systems.

-

Oil & Gas Operations: Supports SCADA and compressor control modules in remote environments.

-

Process Manufacturing: Ensures stable instrumentation control in chemical, paper, and steel plants.

Advantages

-

High Signal Integrity: Eight-layer design with optimized ground planes minimizes electromagnetic interference.

-

Robust Protection: Built-in transient suppression and ESD safeguards protect downstream equipment.

-

Diagnostic Transparency: LED indicators and self-test firmware simplify maintenance and fault isolation.

-

Wide Environmental Tolerance: Reliable operation under extreme temperature, vibration, and humidity conditions.

-

Seamless Integration: Native compatibility with GE Mark VIe and other GE automation ecosystems.

-

Long Service Life: High-grade FR4 substrate and conformal coating extend operational longevity.

Frequently Asked Questions (FAQ)

-

What type of bus communication is supported by the IS210BPPH2BLD?

It supports a high-speed internal backplane bus compatible with Mark VIe system architecture.

-

How is signal integrity maintained across the multilayer board?

Ground and power planes are strategically placed to reduce crosstalk and maintain low impedance paths.

-

Does the board provide galvanic isolation between I/O sections?

Yes, opto-isolators are used for critical I/O channels to prevent ground loops.

-

What diagnostic protocols are available for remote monitoring?

It supports Mark VIe diagnostic communications and Modbus/TCP for supervisory systems.

-

How does the board handle power surges or transient spikes?

Integrated TVS diodes and surge suppressors protect sensitive circuitry.

-

Is there onboard firmware for self-testing?

Yes, embedded firmware runs power-on self-tests and reports status to the control processor.

-

What is the maximum supported data throughput?

Up to 66 MHz logic bus frequency, supporting high-speed real-time control loops.

-

Can the board be hot-swapped in a live system?

It can be hot-inserted if the backplane segment is properly de-energized and configured for redundancy.

-

What grounding scheme is recommended for installation?

A single-point earth ground with low impedance is recommended to minimize noise.

-

How is thermal management ensured without active cooling?

Large copper planes and strategic component placement enable efficient heat dissipation under natural convection.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...