Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

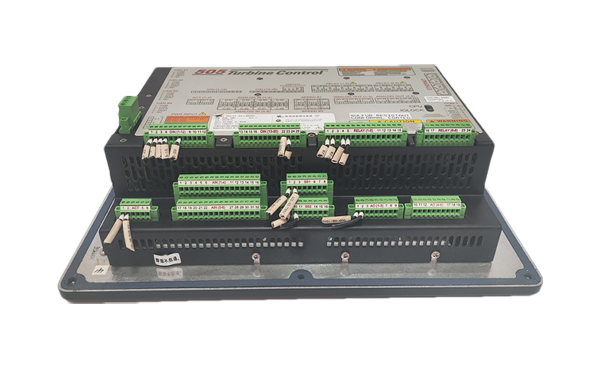

Woodward 9905-976 Overspeed Protection System

Manufacturer:Woodward

Product Number:9905-976

Product Type:Overspeed Protection System

Origin:USA

Dimensions:180 × 120 × 80 mm

Weight :2.3 kg

Views:39

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Woodward 9905-976 Overspeed Protection System is a high-reliability device designed to protect turbines, compressors, and other rotating machinery from overspeed conditions. It continuously monitors rotational speed and activates protective actions when preset limits are exceeded. The system is widely used in industrial, marine, and power generation applications where precise and immediate protection is critical.

Product Advantages

-

Fast Response: Reacts instantly to overspeed conditions to prevent mechanical damage.

-

High Reliability: Proven track record in harsh environments and critical machinery protection.

-

Versatile Integration: Compatible with a wide range of turbine and generator control systems.

-

Redundant Safety Channels: Offers dual-channel design for enhanced reliability and fail-safe operation.

-

Adjustable Setpoints: Allows fine-tuning of activation thresholds to suit specific equipment requirements.

-

Comprehensive Diagnostics: Provides monitoring and status indicators to facilitate maintenance and troubleshooting.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 9905-976 |

| Function | Overspeed Protection System |

| Input Voltage | 24–125 VDC |

| Output Type | Relay / Trip Signal |

| Response Time | < 2 ms |

| Accuracy | ±1% of setpoint |

| Operating Temperature | -40°C to 85°C |

| Storage Temperature | -55°C to 100°C |

| Humidity | 0–95% RH, non-condensing |

| Dimensions | 180 × 120 × 80 mm |

| Weight | 2.3 kg |

| Mounting | Panel or DIN rail |

| Communication | Optional serial interface for diagnostics |

Product Applications

-

Gas turbines in power generation facilities

-

Steam turbines in industrial plants

-

Marine propulsion systems

-

Compressors and generators requiring high-speed monitoring

-

Critical rotating machinery in petrochemical and refining industries

FAQ

Q1: How is the overspeed setpoint adjusted?

The overspeed setpoint can be configured via the system’s front panel adjustment or through remote calibration using a compatible diagnostic tool.

Q2: Can the 9905-976 operate in redundant configurations?

Yes, it supports dual-channel redundancy to ensure continued protection in case of a single-channel failure.

Q3: What is the response time of the protection system?

The system typically reacts within 2 milliseconds of detecting an overspeed condition.

Q4: Does the system provide diagnostic outputs?

Yes, status and diagnostic signals are available for integration with control and monitoring systems.

Q5: What types of machinery can it protect?

It is suitable for turbines, compressors, generators, and other high-speed rotating equipment.

Q6: Is there a provision for remote monitoring?

Optional serial interfaces or network-enabled modules allow remote monitoring and setpoint adjustments.

Q7: How does the system handle transient overspeed conditions?

The device incorporates filtering and debounce logic to avoid false trips during brief speed excursions.

Q8: Can it interface with other Woodward control systems?

Yes, it integrates seamlessly with Woodward turbine and engine control systems.

Q9: What is the system’s operating temperature range?

The system operates reliably between -40°C and 85°C.

Q10: Are there any safety certifications?

The 9905-976 meets industrial safety standards and is certified for critical machinery protection applications.

Woodward 9905-976 Overspeed Protection System

Manufacturer:Woodward

Product Number:9905-976

Product Type:Overspeed Protection System

Origin:USA

Dimensions:180 × 120 × 80 mm

Weight :2.3 kg

Views:39

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Woodward 9905-976 Overspeed Protection System is a high-reliability device designed to protect turbines, compressors, and other rotating machinery from overspeed conditions. It continuously monitors rotational speed and activates protective actions when preset limits are exceeded. The system is widely used in industrial, marine, and power generation applications where precise and immediate protection is critical.

Product Advantages

-

Fast Response: Reacts instantly to overspeed conditions to prevent mechanical damage.

-

High Reliability: Proven track record in harsh environments and critical machinery protection.

-

Versatile Integration: Compatible with a wide range of turbine and generator control systems.

-

Redundant Safety Channels: Offers dual-channel design for enhanced reliability and fail-safe operation.

-

Adjustable Setpoints: Allows fine-tuning of activation thresholds to suit specific equipment requirements.

-

Comprehensive Diagnostics: Provides monitoring and status indicators to facilitate maintenance and troubleshooting.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 9905-976 |

| Function | Overspeed Protection System |

| Input Voltage | 24–125 VDC |

| Output Type | Relay / Trip Signal |

| Response Time | < 2 ms |

| Accuracy | ±1% of setpoint |

| Operating Temperature | -40°C to 85°C |

| Storage Temperature | -55°C to 100°C |

| Humidity | 0–95% RH, non-condensing |

| Dimensions | 180 × 120 × 80 mm |

| Weight | 2.3 kg |

| Mounting | Panel or DIN rail |

| Communication | Optional serial interface for diagnostics |

Product Applications

-

Gas turbines in power generation facilities

-

Steam turbines in industrial plants

-

Marine propulsion systems

-

Compressors and generators requiring high-speed monitoring

-

Critical rotating machinery in petrochemical and refining industries

FAQ

Q1: How is the overspeed setpoint adjusted?

The overspeed setpoint can be configured via the system’s front panel adjustment or through remote calibration using a compatible diagnostic tool.

Q2: Can the 9905-976 operate in redundant configurations?

Yes, it supports dual-channel redundancy to ensure continued protection in case of a single-channel failure.

Q3: What is the response time of the protection system?

The system typically reacts within 2 milliseconds of detecting an overspeed condition.

Q4: Does the system provide diagnostic outputs?

Yes, status and diagnostic signals are available for integration with control and monitoring systems.

Q5: What types of machinery can it protect?

It is suitable for turbines, compressors, generators, and other high-speed rotating equipment.

Q6: Is there a provision for remote monitoring?

Optional serial interfaces or network-enabled modules allow remote monitoring and setpoint adjustments.

Q7: How does the system handle transient overspeed conditions?

The device incorporates filtering and debounce logic to avoid false trips during brief speed excursions.

Q8: Can it interface with other Woodward control systems?

Yes, it integrates seamlessly with Woodward turbine and engine control systems.

Q9: What is the system’s operating temperature range?

The system operates reliably between -40°C and 85°C.

Q10: Are there any safety certifications?

The 9905-976 meets industrial safety standards and is certified for critical machinery protection applications.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...