Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

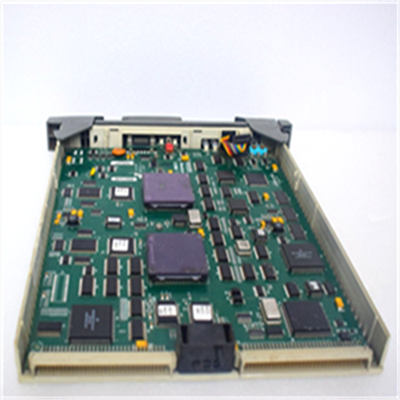

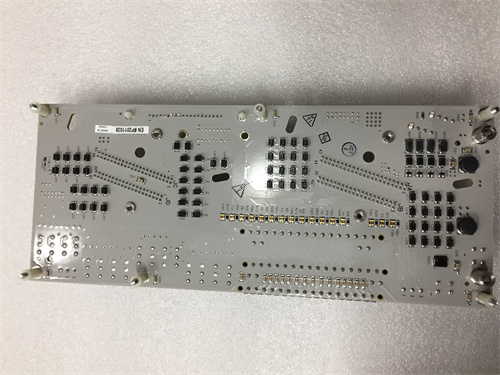

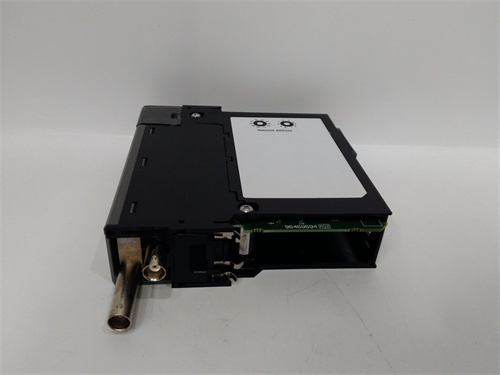

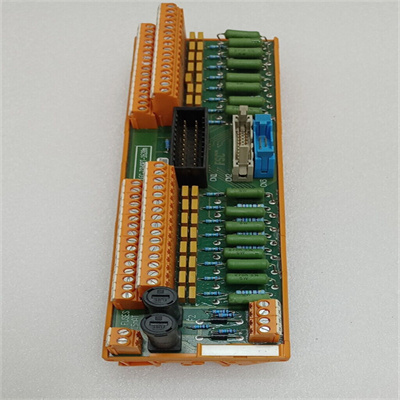

Honeywell 900C75-0560 HC900 C75 Redundant Controller CPU

Manufacturer:Honeywell

Product Number:900C75-0560

Product Type:HC900 C75 Redundant Controller CPU

Origin:USA

Dimensions:137 × 38.1 × 137.16 mm

Weight:0.4 kg

Views:89

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell 900C75-0560 HC900 C75 Redundant Controller CPU is a robust, industrial-grade controller designed for high-availability process automation applications. It forms part of the Honeywell HC900 Hybrid Controller series, widely recognized for its flexibility and reliability in managing complex control processes.

This particular model features redundant CPU capabilities, allowing two CPUs to operate in tandem to provide continuous system operation even if one CPU fails. This makes it a preferred choice for industries where process uptime and system reliability are paramount. The 900C75-0560 supports extensive I/O configurations, multiple communication protocols, and integrates seamlessly into distributed control environments.

Technical Specifications

| Parameter | Details |

|---|---|

| Model Number | 900C75-0560 |

| Product Type | HC900 C75 Redundant Controller CPU |

| Controller Series | HC900 Hybrid Controller |

| CPU Processing Speed | Typical scan time: 25 ms |

| User Memory | 10 MB |

| Maximum I/O Capacity | Supports up to 4,000 I/O points (with expansion modules) |

| Communication Ports | 2 x Ethernet (10/100 Mbps), 1 x RS-485 serial port |

| Supported Protocols | Modbus RTU, Modbus TCP/IP, EtherNet/IP, OPC, Peer-to-Peer |

| Power Supply | 24 VDC |

| Redundancy Features | Full CPU and communication redundancy support |

| Operating Temperature | 0 to 60 °C |

| Storage Temperature | -40 to 85 °C |

| Mounting | DIN Rail |

| Certifications | CE, UL, CSA, RoHS compliant |

| Dimensions (W x H x D) | 137 × 38.1 × 137.16 mm |

| Weight | 0.4 kg |

Product Applications

The Honeywell 900C75-0560 finds wide application in industries where process control reliability is non-negotiable:

-

Chemical Processing Plants: Managing batch and continuous chemical reactions with safety and precision.

-

Oil and Gas Industry: Supervising drilling, refining, and pipeline operations with redundant failover.

-

Pharmaceutical Manufacturing: Ensuring consistent quality through reliable batch process control.

-

Water and Wastewater Treatment: Automation of pumping stations, filtration, and dosing systems.

-

Power Generation: Control and monitoring of turbines, boilers, and cooling systems.

-

Food and Beverage Processing: Temperature control, recipe management, and hygienic automation.

The redundant CPU design ensures no interruption in critical processes, supporting environments where system downtime can lead to significant financial loss or safety risks.

Product Advantages

-

Redundant CPU Architecture: Guarantees uninterrupted control by allowing instant failover between primary and backup CPUs.

-

High Scalability: Easily supports extensive I/O systems to match complex industrial process requirements.

-

Multi-Protocol Support: Ensures compatibility with diverse industrial networks and SCADA systems.

-

Robust Industrial Design: Built to withstand harsh environments with industrial temperature and vibration tolerances.

-

Integrated Security: Features user access control and encrypted configuration management.

-

Efficient Engineering Tools: Configured using Honeywell’s Hybrid Control Designer (HCD) software, enabling fast programming and diagnostics.

-

Comprehensive Diagnostics: Onboard fault detection and monitoring capabilities to reduce troubleshooting time.

-

Modular System Design: Simplifies maintenance and expansion, reducing lifecycle costs.

-

Global Compliance: Meets worldwide safety and quality standards.

-

Optimized Performance: Balanced processing power for both fast scan cycles and large data handling.

Frequently Asked Questions (FAQ)

-

Q: Does the 900C75-0560 support redundant operation only, or can it work standalone?

A: It can operate both as a redundant CPU pair or as a standalone controller depending on system design.

-

Q: What software do I need to configure this controller?

A: Honeywell’s Hybrid Control Designer (HCD) is the dedicated software for configuration, programming, and troubleshooting.

-

Q: How many I/O points can this controller support?

A: It supports up to 4,000 I/O points when combined with expansion modules.

-

Q: What communication protocols are supported?

A: It supports Modbus RTU, Modbus TCP/IP, EtherNet/IP, OPC, and peer-to-peer communication.

-

Q: How fast is the CPU scan time?

A: Typical scan time is 25 milliseconds.

-

Q: Can this controller be integrated into existing SCADA systems?

A: Yes, it is designed for seamless integration with most SCADA and DCS platforms.

-

Q: What kind of redundancy does it provide?

A: Full CPU and communication redundancy ensures that a backup CPU takes over instantly if the primary CPU fails.

-

Q: What are the power requirements?

A: It requires a regulated 24 VDC power supply.

-

Q: How is user security handled?

A: The system includes password protection and the ability to restrict access to configuration and operational functions.

-

Q: Is firmware upgrade supported?

A: Yes, firmware can be upgraded using the HCD software, typically offline during maintenance windows.

Honeywell 900C75-0560 HC900 C75 Redundant Controller CPU

Manufacturer:Honeywell

Product Number:900C75-0560

Product Type:HC900 C75 Redundant Controller CPU

Origin:USA

Dimensions:137 × 38.1 × 137.16 mm

Weight:0.4 kg

Views:89

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell 900C75-0560 HC900 C75 Redundant Controller CPU is a robust, industrial-grade controller designed for high-availability process automation applications. It forms part of the Honeywell HC900 Hybrid Controller series, widely recognized for its flexibility and reliability in managing complex control processes.

This particular model features redundant CPU capabilities, allowing two CPUs to operate in tandem to provide continuous system operation even if one CPU fails. This makes it a preferred choice for industries where process uptime and system reliability are paramount. The 900C75-0560 supports extensive I/O configurations, multiple communication protocols, and integrates seamlessly into distributed control environments.

Technical Specifications

| Parameter | Details |

|---|---|

| Model Number | 900C75-0560 |

| Product Type | HC900 C75 Redundant Controller CPU |

| Controller Series | HC900 Hybrid Controller |

| CPU Processing Speed | Typical scan time: 25 ms |

| User Memory | 10 MB |

| Maximum I/O Capacity | Supports up to 4,000 I/O points (with expansion modules) |

| Communication Ports | 2 x Ethernet (10/100 Mbps), 1 x RS-485 serial port |

| Supported Protocols | Modbus RTU, Modbus TCP/IP, EtherNet/IP, OPC, Peer-to-Peer |

| Power Supply | 24 VDC |

| Redundancy Features | Full CPU and communication redundancy support |

| Operating Temperature | 0 to 60 °C |

| Storage Temperature | -40 to 85 °C |

| Mounting | DIN Rail |

| Certifications | CE, UL, CSA, RoHS compliant |

| Dimensions (W x H x D) | 137 × 38.1 × 137.16 mm |

| Weight | 0.4 kg |

Product Applications

The Honeywell 900C75-0560 finds wide application in industries where process control reliability is non-negotiable:

-

Chemical Processing Plants: Managing batch and continuous chemical reactions with safety and precision.

-

Oil and Gas Industry: Supervising drilling, refining, and pipeline operations with redundant failover.

-

Pharmaceutical Manufacturing: Ensuring consistent quality through reliable batch process control.

-

Water and Wastewater Treatment: Automation of pumping stations, filtration, and dosing systems.

-

Power Generation: Control and monitoring of turbines, boilers, and cooling systems.

-

Food and Beverage Processing: Temperature control, recipe management, and hygienic automation.

The redundant CPU design ensures no interruption in critical processes, supporting environments where system downtime can lead to significant financial loss or safety risks.

Product Advantages

-

Redundant CPU Architecture: Guarantees uninterrupted control by allowing instant failover between primary and backup CPUs.

-

High Scalability: Easily supports extensive I/O systems to match complex industrial process requirements.

-

Multi-Protocol Support: Ensures compatibility with diverse industrial networks and SCADA systems.

-

Robust Industrial Design: Built to withstand harsh environments with industrial temperature and vibration tolerances.

-

Integrated Security: Features user access control and encrypted configuration management.

-

Efficient Engineering Tools: Configured using Honeywell’s Hybrid Control Designer (HCD) software, enabling fast programming and diagnostics.

-

Comprehensive Diagnostics: Onboard fault detection and monitoring capabilities to reduce troubleshooting time.

-

Modular System Design: Simplifies maintenance and expansion, reducing lifecycle costs.

-

Global Compliance: Meets worldwide safety and quality standards.

-

Optimized Performance: Balanced processing power for both fast scan cycles and large data handling.

Frequently Asked Questions (FAQ)

-

Q: Does the 900C75-0560 support redundant operation only, or can it work standalone?

A: It can operate both as a redundant CPU pair or as a standalone controller depending on system design.

-

Q: What software do I need to configure this controller?

A: Honeywell’s Hybrid Control Designer (HCD) is the dedicated software for configuration, programming, and troubleshooting.

-

Q: How many I/O points can this controller support?

A: It supports up to 4,000 I/O points when combined with expansion modules.

-

Q: What communication protocols are supported?

A: It supports Modbus RTU, Modbus TCP/IP, EtherNet/IP, OPC, and peer-to-peer communication.

-

Q: How fast is the CPU scan time?

A: Typical scan time is 25 milliseconds.

-

Q: Can this controller be integrated into existing SCADA systems?

A: Yes, it is designed for seamless integration with most SCADA and DCS platforms.

-

Q: What kind of redundancy does it provide?

A: Full CPU and communication redundancy ensures that a backup CPU takes over instantly if the primary CPU fails.

-

Q: What are the power requirements?

A: It requires a regulated 24 VDC power supply.

-

Q: How is user security handled?

A: The system includes password protection and the ability to restrict access to configuration and operational functions.

-

Q: Is firmware upgrade supported?

A: Yes, firmware can be upgraded using the HCD software, typically offline during maintenance windows.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...