Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

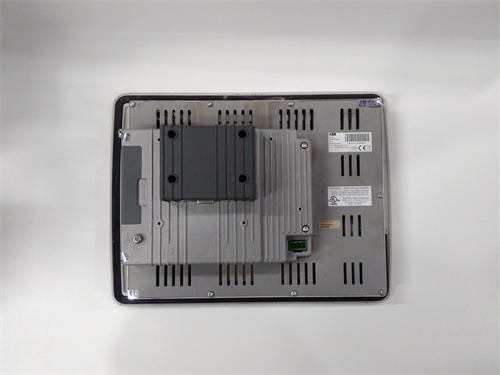

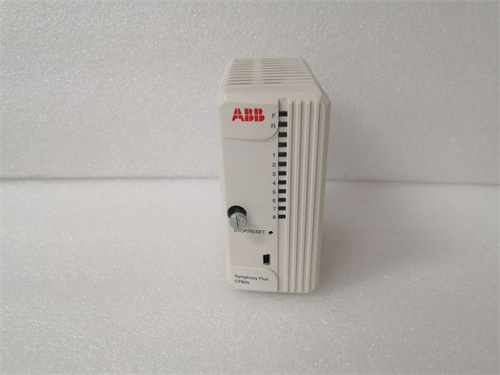

ABB PCD235B101 3BHE032025R0101 High-Performance DCS Controller

Manufacturer:ABB

Product Number:ABB PCD235B101 3BHE032025R0101

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

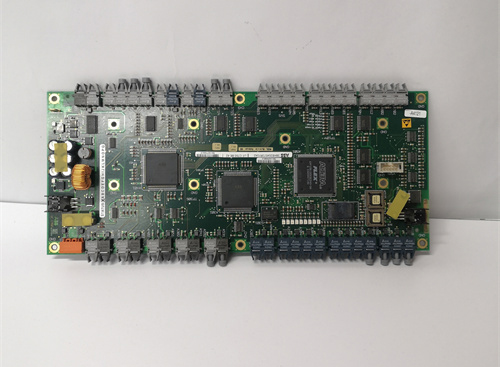

The ABB 3BHE032025R0101 PCD235B101 is a flagship redundant process control module for Symphony Plus DCS, engineered to handle the most critical industrial control tasks. At its core, a dual-core 1GHz ARM Cortex-A9 processor splits workloads dynamically: one core executes real-time control logic (PID, sequential function charts), while the second manages communication, protocol processing, and data logging—eliminating the bottlenecks common in single-core controllers. The 2GB DDR4 RAM and 4GB eMMC flash provide ample capacity for complex applications, with wear leveling on the flash ensuring a 15-year lifespan in 24/7 operation.

Key Technical Specifications

- Model Number: ABB 3BHE032025R0101 PCD235B101

- Manufacturer: ABB Power Automation Division

- CPU Architecture: 32-bit ARM Cortex-A9 dual-core, 1GHz clock speed

- Memory Configuration: 2GB DDR4 RAM (volatile), 4GB eMMC flash (non-volatile, wear-leveled)

- Redundancy Support: 1+1 hot-standby, automatic failover <5ms, sync via dedicated 1Gbps backplane link

- Communication Ports: 4 × 10/100/1000Mbps Ethernet (2 for control, 2 for redundancy/sync), 1 × RS485 (Modbus RTU)

- Protocol Support: IEC 61850 (GOOSE/MMS), Profinet IO, Modbus TCP/RTU, OPC UA, DNP3

- Power Supply: Dual 24VDC ±10% inputs, 1.2A typical per controller (no load)

- Operating Temperature: -20°C to +65°C (-4°F to +149°F)

- Isolation Rating: 2kV AC (signal to power); 1kV AC (channel to channel)

- Compatibility: ABB Symphony Plus I/O modules (AI835A, DI830, AO830), Control Builder M software, 3BHE series redundancy kits

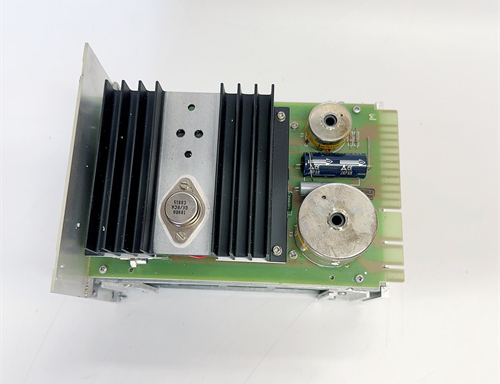

- Mechanical Design: Rack-mount (3U height), metal chassis, conformal-coated PCB (IP20)

- Certifications: IEC 61508 (SIL 3), CE, UL 508, ATEX Zone 2, ISO 13849-1, RoHS 2.0

- Control Capacity: Up to 2,000 PID loops; 30,000 I/O points (max configuration)

Field Application & Problem Solved

In critical industrial environments—coal-fired power plants, LNG liquefaction trains, petrochemical refineries—generic control modules fail to deliver the redundancy and processing power needed for high-stakes control loops. A Midwest coal plant lost $1.9M in a 12-hour outage when a single-point generic controller failed, shutting down the boiler feedwater control system. Legacy modules also struggle with complex protocol integration: a Gulf Coast LNG facility spent $80k on external gateways to connect a third-party controller to IEC 61850 devices, leading to 4 hours of monthly downtime from gateway failures.

You’ll find this module as the core of Symphony Plus DCS racks in mission-critical applications: boiler control in Pennsylvania coal plants, liquefaction train control in Qatar LNG facilities, and reactor temperature control in Texas petrochemical refineries. Its core value is fail-safe redundancy + enterprise-grade processing + native protocol support. The 1+1 hot-standby design eliminated the Midwest plant’s single-point failures—zero unplanned outages in 4 years. At the LNG facility, native IEC 61850 integration replaced 6 external gateways, cutting downtime to 15 minutes monthly and saving $60k/year in maintenance.

For a European gas-fired power plant, SIL 3 certification ensured compliance with grid stability regulations, avoiding $320k in non-compliance fines. Its 1GHz dual-core CPU also handled 1,200 concurrent PID loops (boiler, turbine, emissions control) without scan time overruns—something the previous generic module (800MHz single-core) couldn’t manage, leading to 2% lower fuel efficiency.

Installation & Maintenance Pitfalls

- Redundancy Sync Link—Only ABB-Certified Cabling: Rookies use generic Cat6 cables for the 1Gbps sync link, causing intermittent redundancy drops. A North Carolina power plant did this; the standby controller failed to sync during a voltage sag, triggering a 90-minute shutdown. Use ABB’s 3BSE048901R1 shielded Cat6A cable (max length 3m) and terminate with ABB-approved connectors—generic cables can’t handle the sync link’s bandwidth requirements.

- Firmware Version Lock—Match to DCS Core: Outdated module firmware (pre-v7.0) with Symphony Plus DCS v8.0+ causes communication failures. A Texas refinery made this mistake, losing 3 hours of production when the PCD235B101 couldn’t communicate with the DCS historian. Update firmware via ABB’s Service Port using Control Builder M v7.5+; verify firmware compatibility with the DCS core version (check ABB’s release notes).

- Overloading Control Loops—Respect CPU Limits: Cramming 2,500 PID loops into a module rated for 2,000 causes scan time overruns (>100ms vs. target 50ms). A Pennsylvania chemical plant did this, leading to unstable reactor temperature control and 5% more product waste. Use DCS diagnostics to monitor loop execution time; keep total loops <80% of rated capacity (1,600) for margin.

- Dual Power Inputs—Separate UPS Sources: Wiring both power inputs to one UPS defeats redundancy. A Florida LNG plant did this; a UPS failure took down both controllers, triggering a 3-hour liquefaction train shutdown. Feed Controller A from the plant’s main UPS, Controller B from the emergency backup UPS. Configure the DCS to alarm if either input drops below 20VDC.

Redundancy is engineered for zero disruption: the primary and standby controllers sync data (loop setpoints, I/O status, alarm logs) at 1ms intervals via a dedicated 1Gbps backplane link. If the primary detects a fault (CPU error, power loss, communication failure), the standby takes over in <5ms—faster than the DCS I/O’s data hold time, so no process upset. The module’s dual power inputs and redundant communication paths add layers of resilience.

Native support for IEC 61850 (GOOSE/MMS) is critical for power and LNG applications, enabling seamless integration with smart devices (protection relays, smart transmitters) without external gateways. The conformal-coated PCB and metal chassis protect against dust, moisture, and chemical vapors—essential for coal plants (fly ash) and refineries (corrosive vapors).

What sets it apart from generic controllers is the balance of performance, redundancy, and compliance. It’s factory-calibrated for Symphony Plus DCS, eliminating custom integration work, and SIL 3 certification ensures it meets the strictest safety standards for critical control. For facilities where downtime costs $20k+/minute, this module isn’t just a controller—it’s a mission-critical asset that keeps processes running safely, efficiently, and in compliance.

ABB PCD235B101 3BHE032025R0101 High-Performance DCS Controller

Manufacturer:ABB

Product Number:ABB PCD235B101 3BHE032025R0101

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB 3BHE032025R0101 PCD235B101 is a flagship redundant process control module for Symphony Plus DCS, engineered to handle the most critical industrial control tasks. At its core, a dual-core 1GHz ARM Cortex-A9 processor splits workloads dynamically: one core executes real-time control logic (PID, sequential function charts), while the second manages communication, protocol processing, and data logging—eliminating the bottlenecks common in single-core controllers. The 2GB DDR4 RAM and 4GB eMMC flash provide ample capacity for complex applications, with wear leveling on the flash ensuring a 15-year lifespan in 24/7 operation.

Key Technical Specifications

- Model Number: ABB 3BHE032025R0101 PCD235B101

- Manufacturer: ABB Power Automation Division

- CPU Architecture: 32-bit ARM Cortex-A9 dual-core, 1GHz clock speed

- Memory Configuration: 2GB DDR4 RAM (volatile), 4GB eMMC flash (non-volatile, wear-leveled)

- Redundancy Support: 1+1 hot-standby, automatic failover <5ms, sync via dedicated 1Gbps backplane link

- Communication Ports: 4 × 10/100/1000Mbps Ethernet (2 for control, 2 for redundancy/sync), 1 × RS485 (Modbus RTU)

- Protocol Support: IEC 61850 (GOOSE/MMS), Profinet IO, Modbus TCP/RTU, OPC UA, DNP3

- Power Supply: Dual 24VDC ±10% inputs, 1.2A typical per controller (no load)

- Operating Temperature: -20°C to +65°C (-4°F to +149°F)

- Isolation Rating: 2kV AC (signal to power); 1kV AC (channel to channel)

- Compatibility: ABB Symphony Plus I/O modules (AI835A, DI830, AO830), Control Builder M software, 3BHE series redundancy kits

- Mechanical Design: Rack-mount (3U height), metal chassis, conformal-coated PCB (IP20)

- Certifications: IEC 61508 (SIL 3), CE, UL 508, ATEX Zone 2, ISO 13849-1, RoHS 2.0

- Control Capacity: Up to 2,000 PID loops; 30,000 I/O points (max configuration)

Field Application & Problem Solved

In critical industrial environments—coal-fired power plants, LNG liquefaction trains, petrochemical refineries—generic control modules fail to deliver the redundancy and processing power needed for high-stakes control loops. A Midwest coal plant lost $1.9M in a 12-hour outage when a single-point generic controller failed, shutting down the boiler feedwater control system. Legacy modules also struggle with complex protocol integration: a Gulf Coast LNG facility spent $80k on external gateways to connect a third-party controller to IEC 61850 devices, leading to 4 hours of monthly downtime from gateway failures.

You’ll find this module as the core of Symphony Plus DCS racks in mission-critical applications: boiler control in Pennsylvania coal plants, liquefaction train control in Qatar LNG facilities, and reactor temperature control in Texas petrochemical refineries. Its core value is fail-safe redundancy + enterprise-grade processing + native protocol support. The 1+1 hot-standby design eliminated the Midwest plant’s single-point failures—zero unplanned outages in 4 years. At the LNG facility, native IEC 61850 integration replaced 6 external gateways, cutting downtime to 15 minutes monthly and saving $60k/year in maintenance.

For a European gas-fired power plant, SIL 3 certification ensured compliance with grid stability regulations, avoiding $320k in non-compliance fines. Its 1GHz dual-core CPU also handled 1,200 concurrent PID loops (boiler, turbine, emissions control) without scan time overruns—something the previous generic module (800MHz single-core) couldn’t manage, leading to 2% lower fuel efficiency.

Installation & Maintenance Pitfalls

- Redundancy Sync Link—Only ABB-Certified Cabling: Rookies use generic Cat6 cables for the 1Gbps sync link, causing intermittent redundancy drops. A North Carolina power plant did this; the standby controller failed to sync during a voltage sag, triggering a 90-minute shutdown. Use ABB’s 3BSE048901R1 shielded Cat6A cable (max length 3m) and terminate with ABB-approved connectors—generic cables can’t handle the sync link’s bandwidth requirements.

- Firmware Version Lock—Match to DCS Core: Outdated module firmware (pre-v7.0) with Symphony Plus DCS v8.0+ causes communication failures. A Texas refinery made this mistake, losing 3 hours of production when the PCD235B101 couldn’t communicate with the DCS historian. Update firmware via ABB’s Service Port using Control Builder M v7.5+; verify firmware compatibility with the DCS core version (check ABB’s release notes).

- Overloading Control Loops—Respect CPU Limits: Cramming 2,500 PID loops into a module rated for 2,000 causes scan time overruns (>100ms vs. target 50ms). A Pennsylvania chemical plant did this, leading to unstable reactor temperature control and 5% more product waste. Use DCS diagnostics to monitor loop execution time; keep total loops <80% of rated capacity (1,600) for margin.

- Dual Power Inputs—Separate UPS Sources: Wiring both power inputs to one UPS defeats redundancy. A Florida LNG plant did this; a UPS failure took down both controllers, triggering a 3-hour liquefaction train shutdown. Feed Controller A from the plant’s main UPS, Controller B from the emergency backup UPS. Configure the DCS to alarm if either input drops below 20VDC.

Redundancy is engineered for zero disruption: the primary and standby controllers sync data (loop setpoints, I/O status, alarm logs) at 1ms intervals via a dedicated 1Gbps backplane link. If the primary detects a fault (CPU error, power loss, communication failure), the standby takes over in <5ms—faster than the DCS I/O’s data hold time, so no process upset. The module’s dual power inputs and redundant communication paths add layers of resilience.

Native support for IEC 61850 (GOOSE/MMS) is critical for power and LNG applications, enabling seamless integration with smart devices (protection relays, smart transmitters) without external gateways. The conformal-coated PCB and metal chassis protect against dust, moisture, and chemical vapors—essential for coal plants (fly ash) and refineries (corrosive vapors).

What sets it apart from generic controllers is the balance of performance, redundancy, and compliance. It’s factory-calibrated for Symphony Plus DCS, eliminating custom integration work, and SIL 3 certification ensures it meets the strictest safety standards for critical control. For facilities where downtime costs $20k+/minute, this module isn’t just a controller—it’s a mission-critical asset that keeps processes running safely, efficiently, and in compliance.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...