Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

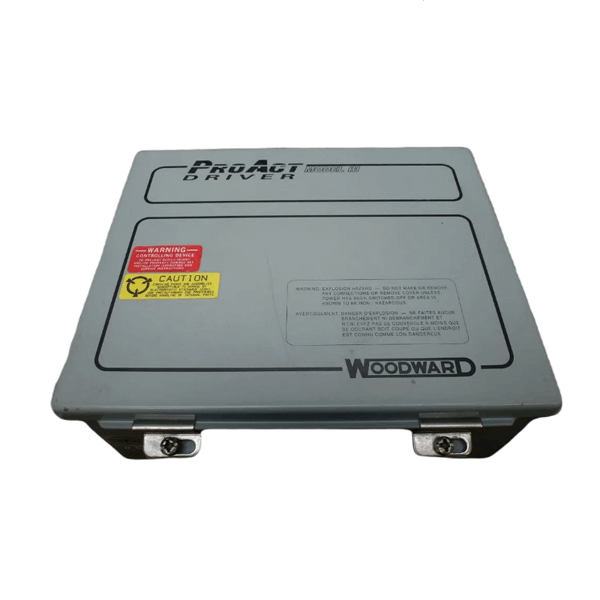

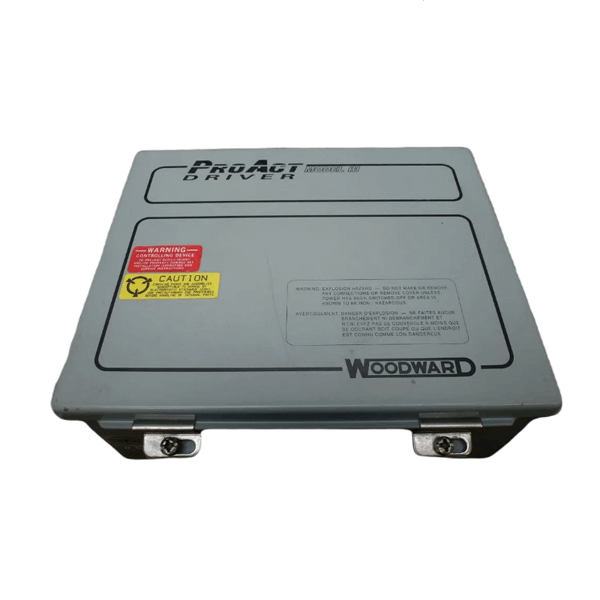

Woodward 9905-387 ProAct drive Modules

Manufacturer:Woodward

Product Number:9905-387

Condition:ProAct drive modules

Origin:USA

Dimensions:120 x 90 x 60 mm

Weight:1 kg

Views:26

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

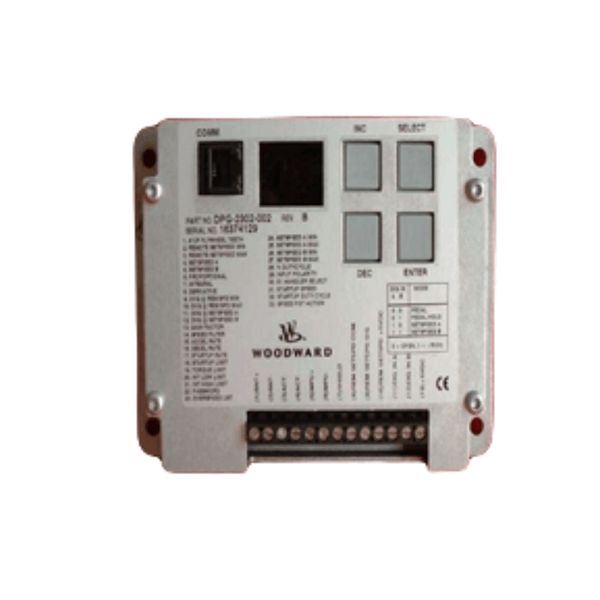

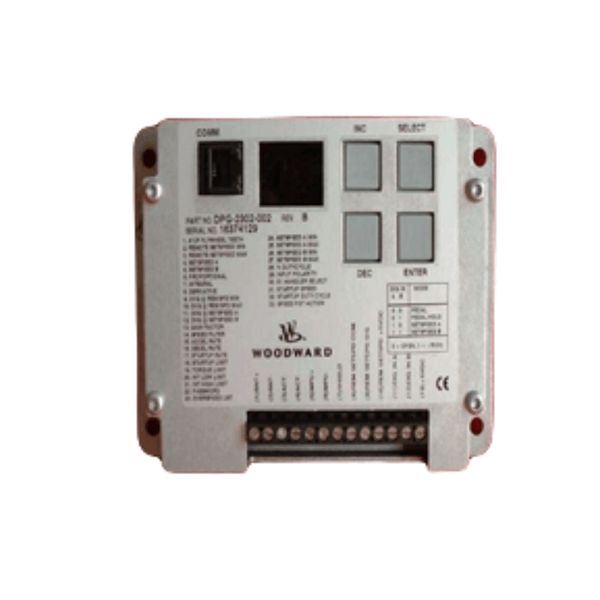

It features flexible configuration options via the built-in keypad or serial interface, allowing it to be adapted to various application demands. It supports isochronous load sharing, droop operation, and provides PID loop-based speed control for both single and parallel unit operations.

This controller is an integral part of critical control systems in power generation, marine propulsion, and industrial process operations, where stable speed and load control is non-negotiable.

Product Advantages

-

High Accuracy Control: Maintains engine or turbine speed precisely through advanced PID control algorithms.

-

Multi-functionality: Combines speed control, load sharing, and system monitoring in one compact unit.

-

Flexible Configuration: Setup can be done via front panel keypad or Modbus-compatible serial interface.

-

Rugged Design: Built to operate in harsh industrial environments with high reliability.

-

Remote Operation Ready: Integrated communications for remote monitoring and control.

-

Wide Application Support: Compatible with a wide range of prime movers and actuator systems.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | Woodward 9905-387 |

| Series | 2301D Digital Load Sharing and Speed Control |

| Power Supply | 18–40 VDC |

| Power Consumption | Less than 15 W typical |

| Speed Range | 500 to 13,000 Hz (sensed speed frequency input) |

| Communication | RS-232 or RS-485, Modbus® RTU Protocol |

| Control Mode | Isochronous, Droop, Base Load, Load Sharing |

| Display Interface | 4-line LCD with keypad |

| Ambient Operating Temp | –40 °C to +70 °C |

| Storage Temperature | –55 °C to +105 °C |

| Humidity Resistance | 95% RH non-condensing |

| Enclosure Type | Metal case, Panel mounted |

| Mounting Style | Panel-mounted with screw holes |

| Dimensions | 120 x 90 x 60 mm |

| Weight | 1 kg |

| Certifications | CE, CSA Certified, RoHS compliant |

Product Applications

-

Power Generation Systems: Ensures optimal engine speed and load balancing across multiple generators.

-

Marine Propulsion: Used to control main engine speeds in ships and vessels for efficient marine propulsion.

-

Industrial Turbines: Controls steam or gas turbine speed and output power reliably.

-

Oil & Gas Facilities: Maintains operational stability in critical compressor or pump control systems.

-

Cogeneration Plants: Provides load sharing and stability between gas engines and utility supply.

-

Remote Power Units: Perfect for off-grid or backup power systems requiring autonomous speed regulation.

Installation and Setup Instructions

-

Mounting:

-

Secure the unit using the panel-mount screw holes provided.

-

Ensure proper ventilation around the controller for heat dissipation.

-

-

Electrical Connections:

-

Connect the power supply (18–40 VDC) to the designated terminals.

-

Input the speed sensor signal to the speed input terminals.

-

Connect actuator output and feedback signals as specified in the manual.

-

-

Communication Setup:

-

Connect RS-232 or RS-485 cable to allow configuration or remote monitoring.

-

Ensure Modbus settings match your supervisory system (baud rate, parity, etc.).

-

-

Configuration:

-

Use the onboard keypad and display to access menu settings.

-

Adjust PID settings, speed setpoints, and mode of operation.

-

Save configurations to onboard memory.

-

-

Testing & Commissioning:

-

Run functional tests to validate speed and load control.

-

Monitor performance under various load conditions.

-

FAQs

Q1: What is the main function of the Woodward 9905-387 controller?

A1: The 9905-387 is used to regulate engine or turbine speed and to facilitate load sharing among parallel units.

Q2: Can this controller handle both isochronous and droop control modes?

A2: Yes, it supports both modes and allows switching based on application needs.

Q3: Is the 9905-387 suitable for outdoor installations?

A3: While rugged, the unit is designed for panel mounting inside control cabinets. Enclosure protection should be considered for outdoor setups.

Q4: What types of engines can it control?

A4: It is compatible with diesel, gas, and turbine engines, provided proper actuator and speed feedback systems are in place.

Q5: How is the configuration performed?

A5: Configuration is done via front panel keypad or through Modbus using RS-232/RS-485 communication.

Q6: Does the unit store configuration settings after power loss?

A6: Yes, settings are saved in non-volatile memory and persist through power cycles.

Q7: Can it be used in marine vessels?

A7: Absolutely. It is widely used for speed control in marine propulsion and auxiliary generators.

Q8: What’s the typical startup time after power is applied?

A8: The system typically initializes in a few seconds, depending on configuration complexity.

Q9: Is software needed for configuration?

A9: No software is strictly required, though optional tools are available for PC-based setup.

Q10: How long is the expected service life?

A10: With proper installation and environmental control, it can operate reliably for over 5 years.

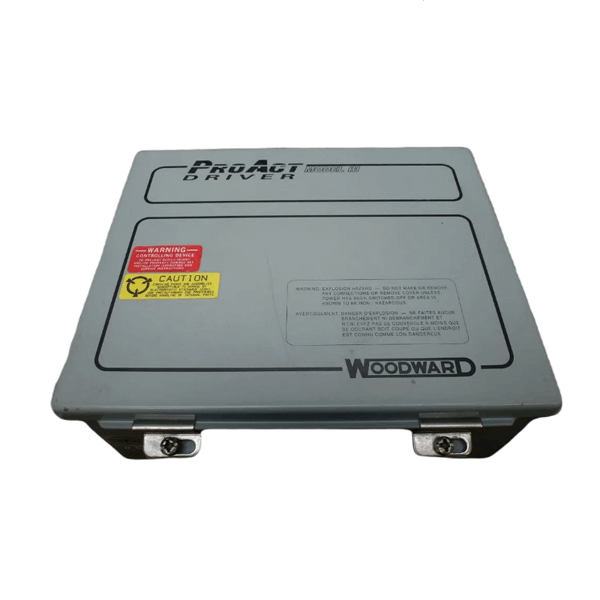

Woodward 9905-387 ProAct drive Modules

Manufacturer:Woodward

Product Number:9905-387

Condition:ProAct drive modules

Origin:USA

Dimensions:120 x 90 x 60 mm

Weight:1 kg

Views:26

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

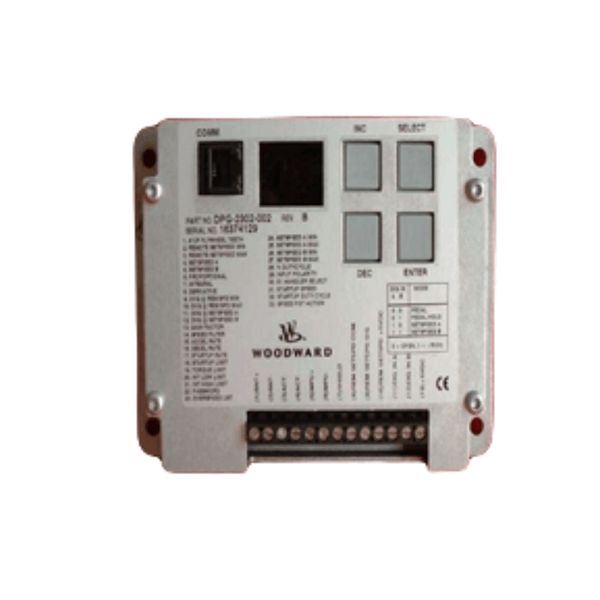

It features flexible configuration options via the built-in keypad or serial interface, allowing it to be adapted to various application demands. It supports isochronous load sharing, droop operation, and provides PID loop-based speed control for both single and parallel unit operations.

This controller is an integral part of critical control systems in power generation, marine propulsion, and industrial process operations, where stable speed and load control is non-negotiable.

Product Advantages

-

High Accuracy Control: Maintains engine or turbine speed precisely through advanced PID control algorithms.

-

Multi-functionality: Combines speed control, load sharing, and system monitoring in one compact unit.

-

Flexible Configuration: Setup can be done via front panel keypad or Modbus-compatible serial interface.

-

Rugged Design: Built to operate in harsh industrial environments with high reliability.

-

Remote Operation Ready: Integrated communications for remote monitoring and control.

-

Wide Application Support: Compatible with a wide range of prime movers and actuator systems.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | Woodward 9905-387 |

| Series | 2301D Digital Load Sharing and Speed Control |

| Power Supply | 18–40 VDC |

| Power Consumption | Less than 15 W typical |

| Speed Range | 500 to 13,000 Hz (sensed speed frequency input) |

| Communication | RS-232 or RS-485, Modbus® RTU Protocol |

| Control Mode | Isochronous, Droop, Base Load, Load Sharing |

| Display Interface | 4-line LCD with keypad |

| Ambient Operating Temp | –40 °C to +70 °C |

| Storage Temperature | –55 °C to +105 °C |

| Humidity Resistance | 95% RH non-condensing |

| Enclosure Type | Metal case, Panel mounted |

| Mounting Style | Panel-mounted with screw holes |

| Dimensions | 120 x 90 x 60 mm |

| Weight | 1 kg |

| Certifications | CE, CSA Certified, RoHS compliant |

Product Applications

-

Power Generation Systems: Ensures optimal engine speed and load balancing across multiple generators.

-

Marine Propulsion: Used to control main engine speeds in ships and vessels for efficient marine propulsion.

-

Industrial Turbines: Controls steam or gas turbine speed and output power reliably.

-

Oil & Gas Facilities: Maintains operational stability in critical compressor or pump control systems.

-

Cogeneration Plants: Provides load sharing and stability between gas engines and utility supply.

-

Remote Power Units: Perfect for off-grid or backup power systems requiring autonomous speed regulation.

Installation and Setup Instructions

-

Mounting:

-

Secure the unit using the panel-mount screw holes provided.

-

Ensure proper ventilation around the controller for heat dissipation.

-

-

Electrical Connections:

-

Connect the power supply (18–40 VDC) to the designated terminals.

-

Input the speed sensor signal to the speed input terminals.

-

Connect actuator output and feedback signals as specified in the manual.

-

-

Communication Setup:

-

Connect RS-232 or RS-485 cable to allow configuration or remote monitoring.

-

Ensure Modbus settings match your supervisory system (baud rate, parity, etc.).

-

-

Configuration:

-

Use the onboard keypad and display to access menu settings.

-

Adjust PID settings, speed setpoints, and mode of operation.

-

Save configurations to onboard memory.

-

-

Testing & Commissioning:

-

Run functional tests to validate speed and load control.

-

Monitor performance under various load conditions.

-

FAQs

Q1: What is the main function of the Woodward 9905-387 controller?

A1: The 9905-387 is used to regulate engine or turbine speed and to facilitate load sharing among parallel units.

Q2: Can this controller handle both isochronous and droop control modes?

A2: Yes, it supports both modes and allows switching based on application needs.

Q3: Is the 9905-387 suitable for outdoor installations?

A3: While rugged, the unit is designed for panel mounting inside control cabinets. Enclosure protection should be considered for outdoor setups.

Q4: What types of engines can it control?

A4: It is compatible with diesel, gas, and turbine engines, provided proper actuator and speed feedback systems are in place.

Q5: How is the configuration performed?

A5: Configuration is done via front panel keypad or through Modbus using RS-232/RS-485 communication.

Q6: Does the unit store configuration settings after power loss?

A6: Yes, settings are saved in non-volatile memory and persist through power cycles.

Q7: Can it be used in marine vessels?

A7: Absolutely. It is widely used for speed control in marine propulsion and auxiliary generators.

Q8: What’s the typical startup time after power is applied?

A8: The system typically initializes in a few seconds, depending on configuration complexity.

Q9: Is software needed for configuration?

A9: No software is strictly required, though optional tools are available for PC-based setup.

Q10: How long is the expected service life?

A10: With proper installation and environmental control, it can operate reliably for over 5 years.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...