Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

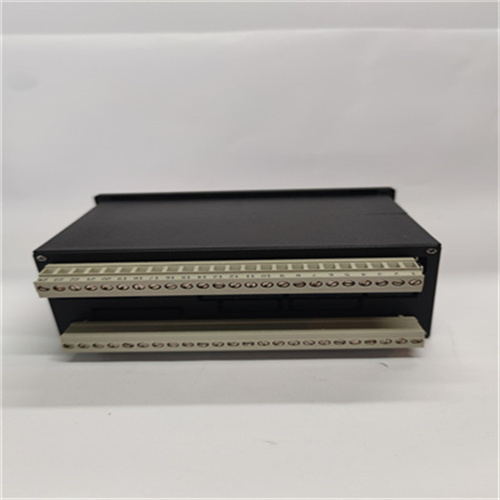

Woodward 8200-205 Overspeed Protection

Manufacturer:Woodward

Product Number:8200-205

Product Type:Overspeed Protection

Origin:USA

Dimensions:482.6 x 310.4 x 142.7 mm

Weight:2.35 kg

Views:39

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

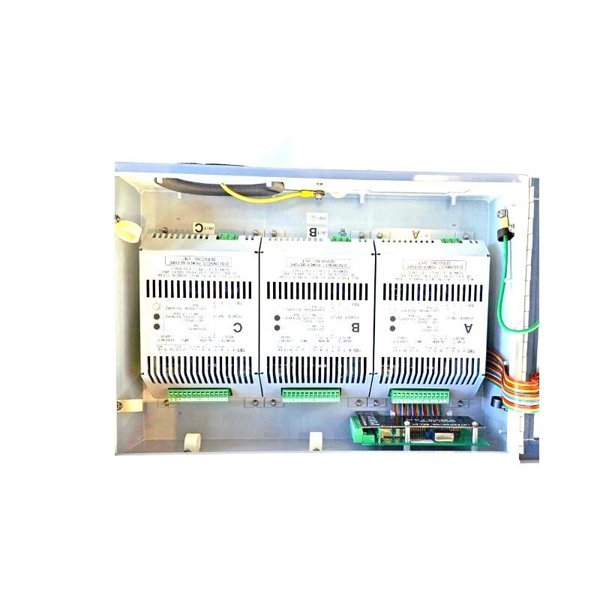

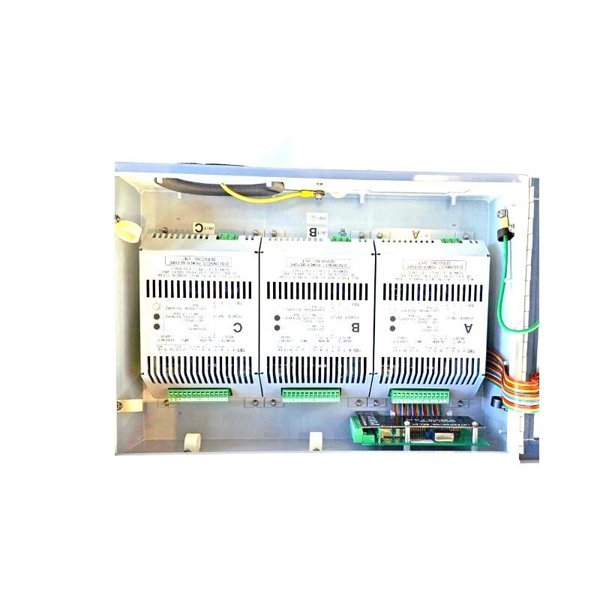

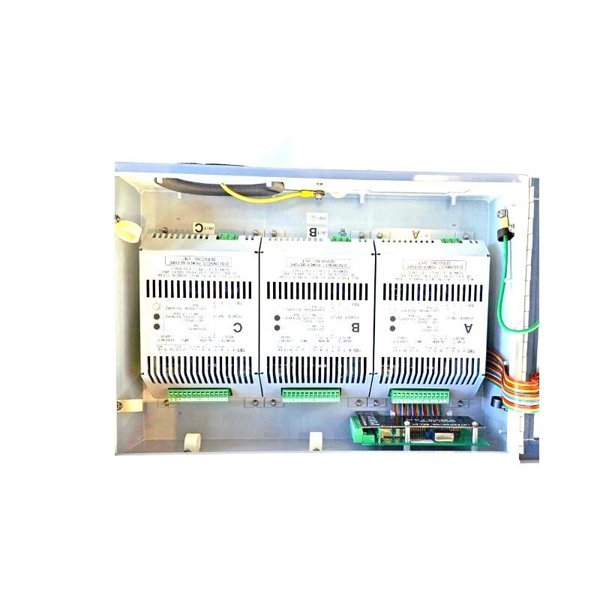

The Woodward 8200-205 is a high-performance overspeed protection system designed for critical rotating machinery. It delivers fast and reliable response to overspeed events, ensuring operational safety in turbines, compressors, and engines. Engineered for harsh industrial environments, this module supports safe shutdown functionality and precise speed monitoring.

Technical Specifications

| Parameter | Value |

|---|---|

| Model | 8200-205 |

| Function | Overspeed Protection Module |

| Inputs | Speed sensors (magnetic/proximity) |

| Outputs | Relay trip outputs, diagnostics |

| Operating Voltage | 18–32 VDC |

| Operating Temperature | –40 °C to +70 °C |

| Response Time | <5 milliseconds |

| Mounting | Panel mount |

| Communication | RS-232 / Modbus |

| Enclosure Rating | IP50 (front panel) |

| Dimensions (W x H x D) | 482.6 x 310.4 x 142.7 mm |

| Weight | 2.35 kg |

Applications

-

Steam and gas turbines

-

Industrial compressors

-

Diesel and gas engines

-

Critical rotating equipment

-

Backup safety in process industries

-

Marine propulsion systems

Advantages

-

Fast response to overspeed conditions

-

Independent safety layer from main control

-

Easy integration with existing control systems

-

High reliability in harsh environments

-

Compliant with industry safety standards

-

Clear diagnostics and alarms

Frequently Asked Questions

Q1: What type of speed sensors can be used with the 8200-205?

A1: It supports magnetic pickups and proximity probes commonly used in turbine applications.

Q2: How fast does the module respond to overspeed conditions?

A2: The response time is less than 5 milliseconds, ensuring rapid protection.

Q3: Does it provide communication with other systems?

A3: Yes, it includes RS-232 and Modbus communication for integration and diagnostics.

Q4: Can the unit operate in outdoor or rugged environments?

A4: Yes, it is designed to function reliably in temperatures from –40 °C to +70 °C.

Q5: Is the system certified for industrial safety standards?

A5: Yes, the 8200-205 meets relevant industry certifications for overspeed protection.

Q6: How is it typically mounted?

A6: The module is designed for panel mounting within control cabinets.

Q7: Can it be used in marine applications?

A7: Yes, it is suitable for marine engines and propulsion systems.

Q8: What power supply is required?

A8: It operates on a DC voltage range of 18–32 VDC.

Q9: Does it include self-diagnostics?

A9: Yes, it features built-in diagnostics for system health and sensor input monitoring.

Q10: What happens during a failure or loss of signal?

A10: The system triggers a safe shutdown to prevent damage or hazards.

Woodward 8200-205 Overspeed Protection

Manufacturer:Woodward

Product Number:8200-205

Product Type:Overspeed Protection

Origin:USA

Dimensions:482.6 x 310.4 x 142.7 mm

Weight:2.35 kg

Views:39

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Woodward 8200-205 is a high-performance overspeed protection system designed for critical rotating machinery. It delivers fast and reliable response to overspeed events, ensuring operational safety in turbines, compressors, and engines. Engineered for harsh industrial environments, this module supports safe shutdown functionality and precise speed monitoring.

Technical Specifications

| Parameter | Value |

|---|---|

| Model | 8200-205 |

| Function | Overspeed Protection Module |

| Inputs | Speed sensors (magnetic/proximity) |

| Outputs | Relay trip outputs, diagnostics |

| Operating Voltage | 18–32 VDC |

| Operating Temperature | –40 °C to +70 °C |

| Response Time | <5 milliseconds |

| Mounting | Panel mount |

| Communication | RS-232 / Modbus |

| Enclosure Rating | IP50 (front panel) |

| Dimensions (W x H x D) | 482.6 x 310.4 x 142.7 mm |

| Weight | 2.35 kg |

Applications

-

Steam and gas turbines

-

Industrial compressors

-

Diesel and gas engines

-

Critical rotating equipment

-

Backup safety in process industries

-

Marine propulsion systems

Advantages

-

Fast response to overspeed conditions

-

Independent safety layer from main control

-

Easy integration with existing control systems

-

High reliability in harsh environments

-

Compliant with industry safety standards

-

Clear diagnostics and alarms

Frequently Asked Questions

Q1: What type of speed sensors can be used with the 8200-205?

A1: It supports magnetic pickups and proximity probes commonly used in turbine applications.

Q2: How fast does the module respond to overspeed conditions?

A2: The response time is less than 5 milliseconds, ensuring rapid protection.

Q3: Does it provide communication with other systems?

A3: Yes, it includes RS-232 and Modbus communication for integration and diagnostics.

Q4: Can the unit operate in outdoor or rugged environments?

A4: Yes, it is designed to function reliably in temperatures from –40 °C to +70 °C.

Q5: Is the system certified for industrial safety standards?

A5: Yes, the 8200-205 meets relevant industry certifications for overspeed protection.

Q6: How is it typically mounted?

A6: The module is designed for panel mounting within control cabinets.

Q7: Can it be used in marine applications?

A7: Yes, it is suitable for marine engines and propulsion systems.

Q8: What power supply is required?

A8: It operates on a DC voltage range of 18–32 VDC.

Q9: Does it include self-diagnostics?

A9: Yes, it features built-in diagnostics for system health and sensor input monitoring.

Q10: What happens during a failure or loss of signal?

A10: The system triggers a safe shutdown to prevent damage or hazards.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...