Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

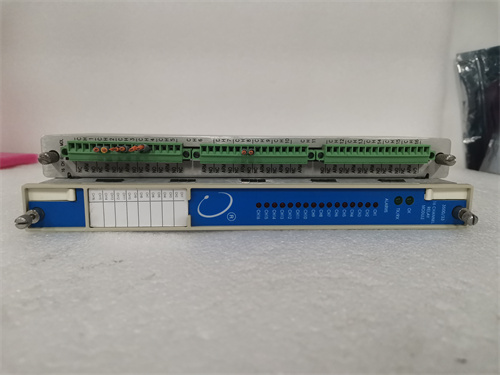

Bently Nevada 1900/65A-00-04-01-00-00 Vibration Monitoring Systems

Module Number:1900/65A-00-04-01-00-00

Product status:Discontinued

Delivery time:In stock

Product status:100% new

Sales country:All over the world

Product situation:one year warranty

Product Description

The Bently Nevada 1900/65A-00-04-01-00-00 is a part of Bently Nevada’s series of vibration monitoring systems, which are primarily used for predictive maintenance in rotating equipment, such as gas and steam turbines, pumps, and compressors. The Bently Nevada system specializes in monitoring the condition of machinery and providing early warning of potential failures or issues.

Overview of Bently Nevada 1900/65A

1. Description:

– The Bently Nevada 1900/65A is typically a part of a vibration monitoring system that provides real-time data concerning the condition and performance of machinery components. It allows for continuous monitoring and data recording, which is vital for predictive maintenance strategies.

2. Key Applications:

– Common applications for the 1900/65A include:

– Vibration monitoring of critical rotating machinery

– Condition assessment to prevent unplanned downtime

– Data collection for analysis in predictive maintenance programs

Key Features

– High-Precision Measurements:

– The module is designed to deliver precise vibration data, which is essential for detecting even minor changes in machinery conditions.

– Compatibility:

– It is compatible with various Bently Nevada monitoring systems and components, enabling integration into existing setups.

– Robust Design:

– Built to withstand harsh industrial environments, ensuring reliability and consistent operation over time.

– Data Analysis Capabilities:

– The system can perform detailed data analysis, support trend monitoring, and provide alarms or notifications based on predefined thresholds.

– Scalability:

– The 1900 series offers scalability, allowing users to expand monitoring capabilities as their needs evolve.

Considerations for Use

– Installation and Configuration:

– Proper installation and configuration are paramount for accurate operation. Carefully follow the manufacturer’s installation manual and guidelines.

– Data Interpretation:

– Users should be familiar with how to interpret the data collected from the 1900/65A, understanding the metrics used in evaluating machinery health.

– Regular Maintenance:

– Regular check-ups and calibrations should be performed to maintain the accuracy and functionality of the monitoring system.

Summary

The Bently Nevada 1900/65A-00-04-01-00-00 is an integral part of vibration monitoring solutions aimed at enhancing the reliability and performance of industrial machinery through detailed condition monitoring. It plays a critical role in predictive maintenance, helping to minimize unplanned downtime and optimize operational efficiency.

Bently Nevada 1900/65A-00-04-01-00-00 Vibration Monitoring Systems

Module Number:1900/65A-00-04-01-00-00

Product status:Discontinued

Delivery time:In stock

Product status:100% new

Sales country:All over the world

Product situation:one year warranty

Product Description

The Bently Nevada 1900/65A-00-04-01-00-00 is a part of Bently Nevada’s series of vibration monitoring systems, which are primarily used for predictive maintenance in rotating equipment, such as gas and steam turbines, pumps, and compressors. The Bently Nevada system specializes in monitoring the condition of machinery and providing early warning of potential failures or issues.

Overview of Bently Nevada 1900/65A

1. Description:

– The Bently Nevada 1900/65A is typically a part of a vibration monitoring system that provides real-time data concerning the condition and performance of machinery components. It allows for continuous monitoring and data recording, which is vital for predictive maintenance strategies.

2. Key Applications:

– Common applications for the 1900/65A include:

– Vibration monitoring of critical rotating machinery

– Condition assessment to prevent unplanned downtime

– Data collection for analysis in predictive maintenance programs

Key Features

– High-Precision Measurements:

– The module is designed to deliver precise vibration data, which is essential for detecting even minor changes in machinery conditions.

– Compatibility:

– It is compatible with various Bently Nevada monitoring systems and components, enabling integration into existing setups.

– Robust Design:

– Built to withstand harsh industrial environments, ensuring reliability and consistent operation over time.

– Data Analysis Capabilities:

– The system can perform detailed data analysis, support trend monitoring, and provide alarms or notifications based on predefined thresholds.

– Scalability:

– The 1900 series offers scalability, allowing users to expand monitoring capabilities as their needs evolve.

Considerations for Use

– Installation and Configuration:

– Proper installation and configuration are paramount for accurate operation. Carefully follow the manufacturer’s installation manual and guidelines.

– Data Interpretation:

– Users should be familiar with how to interpret the data collected from the 1900/65A, understanding the metrics used in evaluating machinery health.

– Regular Maintenance:

– Regular check-ups and calibrations should be performed to maintain the accuracy and functionality of the monitoring system.

Summary

The Bently Nevada 1900/65A-00-04-01-00-00 is an integral part of vibration monitoring solutions aimed at enhancing the reliability and performance of industrial machinery through detailed condition monitoring. It plays a critical role in predictive maintenance, helping to minimize unplanned downtime and optimize operational efficiency.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...