Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

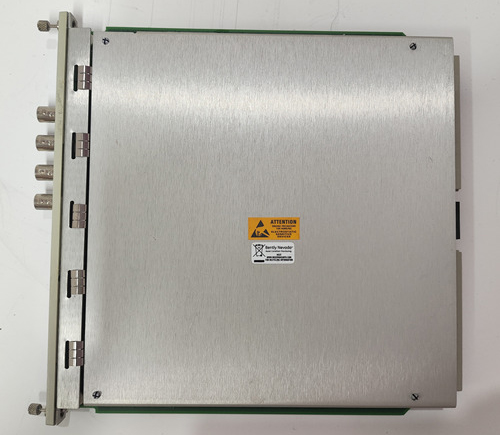

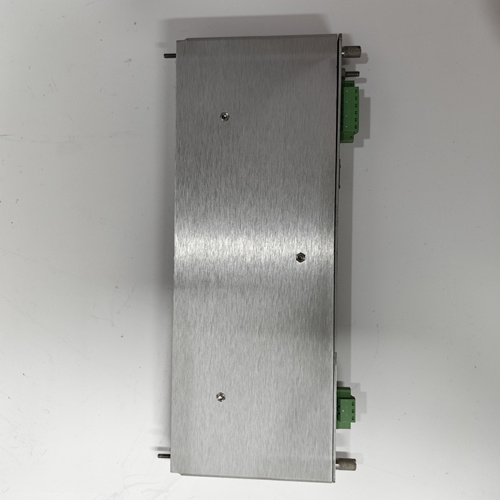

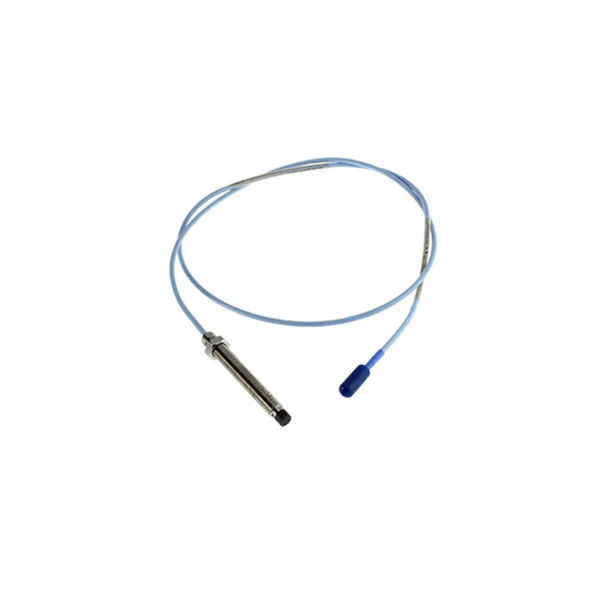

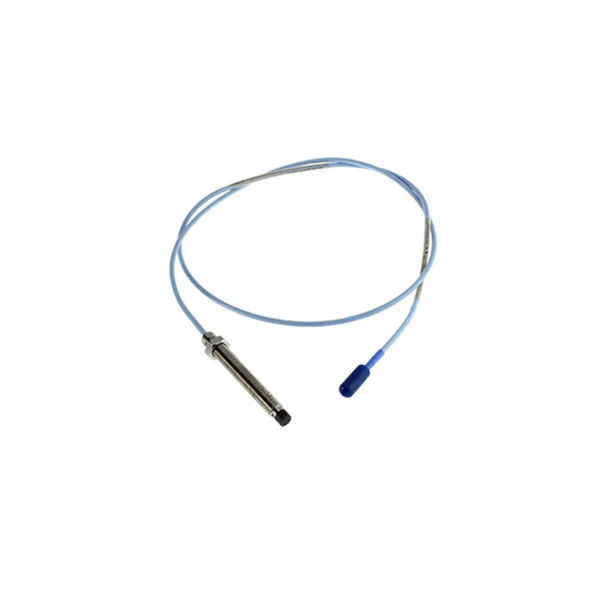

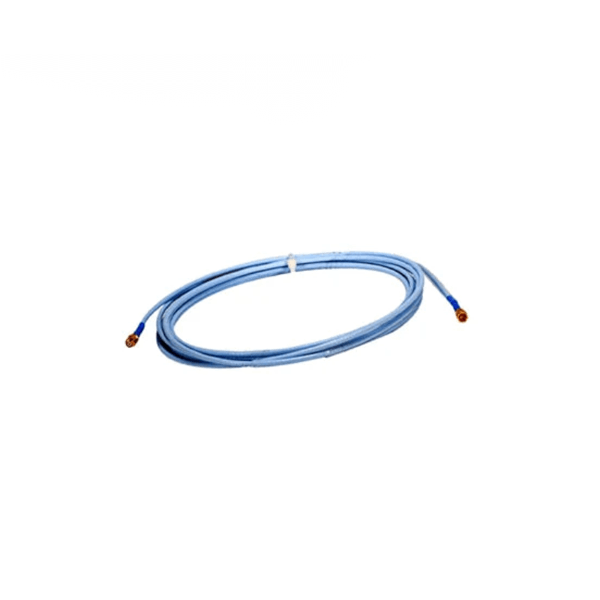

Bently Nevada 330703-000-060-10-02-00 3300 XL 11 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330703-000-060-10-02-00

Condition:3300 XL 11 mm Proximity Probe

Origin:USA

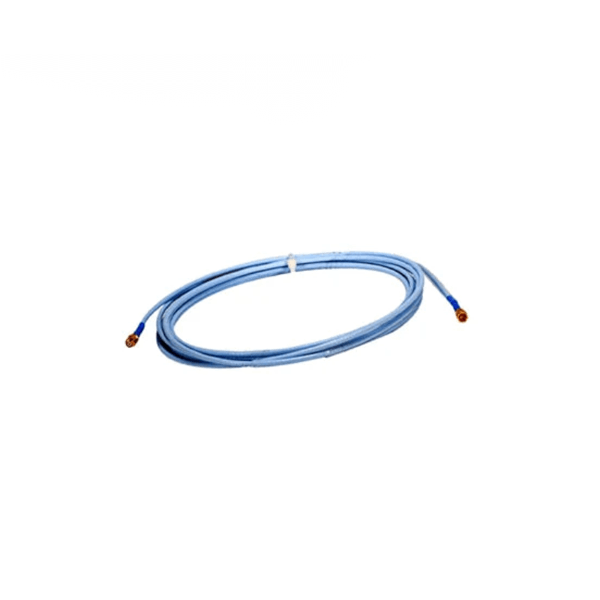

Cable length:1 m

Weight:0.255kg

Views:61

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

Bently Nevada is known for its advanced monitoring solutions, and the 330703-000-060-10-02-00 sensor plays a pivotal role in providing data about the condition of rotating machinery. By offering precise vibration measurement, the sensor can help identify faults like imbalance, misalignment, or bearing wear, allowing maintenance teams to take corrective action before any significant damage occurs.

Key Advantages

-

Precision and Reliability: The sensor provides accurate, real-time vibration data to detect early signs of machine distress.

-

Durability: Built to endure harsh industrial environments, ensuring long-term performance with minimal maintenance.

-

Early Fault Detection: Detects machine conditions before they escalate, reducing downtime and repair costs.

-

Easy Integration: Seamlessly integrates with existing machinery protection systems, offering a versatile solution for various applications.

-

Remote Monitoring: Compatible with Bently Nevada’s monitoring systems for remote access and continuous machine condition tracking.

Technical Specifications

| Feature | Description |

|---|---|

| Model Number | 330703-000-060-10-02-00 |

| Vibration Range | 0.01 to 50 g |

| Operating Temperature | -40°C to +85°C |

| Weight | 0.255kg |

| Cable length | 1 m |

| Mounting Type | Screw Mount |

| Power Supply | 24 V DC |

| Output Signal | 4-20 mA |

| Response Frequency Range | 0.5 Hz to 10 kHz |

| Housing Material | Stainless Steel |

| IP Rating | IP 65 |

Applications

-

Industrial Machinery: Used extensively in monitoring critical machinery like motors, turbines, and compressors.

-

Power Plants: Vital in ensuring the performance of machinery in power generation and distribution.

-

Oil & Gas: Monitors equipment such as pumps, compressors, and gas turbines to prevent failure.

-

Mining: Provides valuable insights into the operational health of mining equipment under extreme conditions.

-

Manufacturing: Used in monitoring pumps, conveyors, and other essential machines to maintain operational efficiency.

Product Advantages

-

Enhanced Safety: Early fault detection helps prevent machinery failures, reducing the risk of accidents and improving worker safety.

-

Cost-Effective Maintenance: By detecting issues early, the need for expensive repairs and unplanned downtime is minimized.

-

Increased Equipment Lifespan: Regular monitoring extends the life of machinery by allowing for timely interventions.

-

Real-Time Data: Continuous data collection ensures that operators always have up-to-date information to make informed decisions.

-

Reduced Downtime: Minimizes production interruptions by enabling predictive maintenance rather than reactive repairs.

-

Versatile Use: Suitable for a wide range of industries, from energy production to manufacturing.

FAQs

Q1: What type of vibration faults can the Bently Nevada 330703-000-060-10-02-00 sensor detect?

A1: This sensor can detect a wide range of vibration faults including imbalance, misalignment, bearing defects, and looseness, which can be critical indicators of machinery failure.

Q2: Is the 330703-000-060-10-02-00 sensor compatible with other Bently Nevada systems?

A2: Yes, it is fully compatible with other Bently Nevada monitoring systems and can be integrated into larger machinery protection and monitoring setups.

Q3: What is the operating temperature range of this sensor?

A3: The operating temperature range is from -40°C to +85°C, making it suitable for harsh industrial environments.

Q4: How does this sensor help with predictive maintenance?

A4: The sensor provides real-time vibration data that can be analyzed to identify early signs of wear and damage, allowing maintenance teams to act before costly repairs are needed.

Q5: Can the sensor output be remotely monitored?

A5: Yes, the sensor is compatible with Bently Nevada’s remote monitoring systems, allowing operators to monitor machinery conditions remotely.

Q6: What type of output signal does the sensor provide?

A6: The sensor provides a 4-20 mA output signal, which can be easily integrated into various control systems.

Q7: Is the sensor resistant to environmental factors?

A7: Yes, the sensor has an IP 65 rating, making it resistant to dust and water ingress, suitable for industrial environments.

Q8: What kind of mounting does this sensor require?

A8: The sensor is designed for screw mounting, ensuring secure attachment to the monitored equipment.

Q9: What is the weight of the sensor?

A9: The weight of the sensor is 0.255kg.

Q10: What is the maximum vibration range that the sensor can measure?

A10: The sensor can measure vibrations ranging from 0.01 to 50 g, covering a wide spectrum of machinery operating conditions.

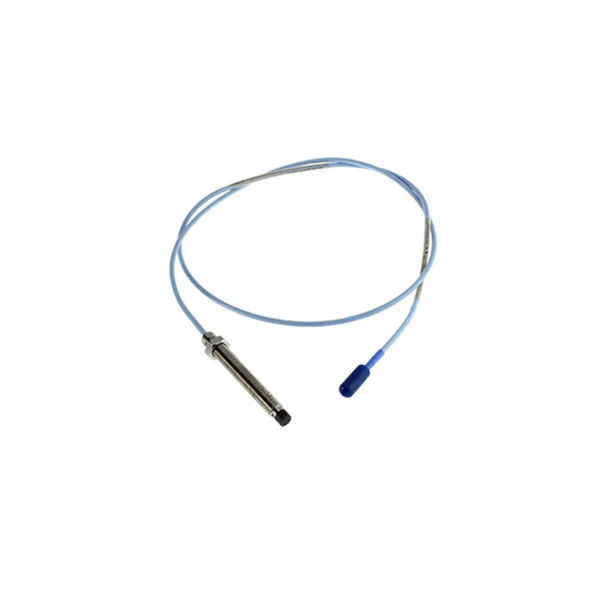

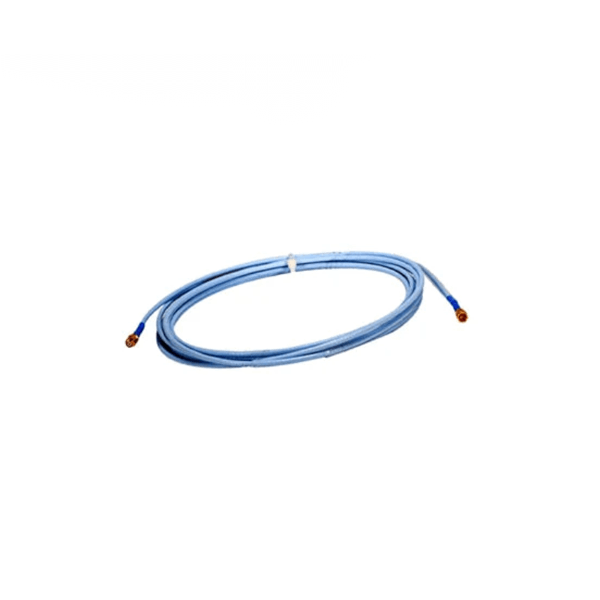

Bently Nevada 330703-000-060-10-02-00 3300 XL 11 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330703-000-060-10-02-00

Condition:3300 XL 11 mm Proximity Probe

Origin:USA

Cable length:1 m

Weight:0.255kg

Views:61

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

Bently Nevada is known for its advanced monitoring solutions, and the 330703-000-060-10-02-00 sensor plays a pivotal role in providing data about the condition of rotating machinery. By offering precise vibration measurement, the sensor can help identify faults like imbalance, misalignment, or bearing wear, allowing maintenance teams to take corrective action before any significant damage occurs.

Key Advantages

-

Precision and Reliability: The sensor provides accurate, real-time vibration data to detect early signs of machine distress.

-

Durability: Built to endure harsh industrial environments, ensuring long-term performance with minimal maintenance.

-

Early Fault Detection: Detects machine conditions before they escalate, reducing downtime and repair costs.

-

Easy Integration: Seamlessly integrates with existing machinery protection systems, offering a versatile solution for various applications.

-

Remote Monitoring: Compatible with Bently Nevada’s monitoring systems for remote access and continuous machine condition tracking.

Technical Specifications

| Feature | Description |

|---|---|

| Model Number | 330703-000-060-10-02-00 |

| Vibration Range | 0.01 to 50 g |

| Operating Temperature | -40°C to +85°C |

| Weight | 0.255kg |

| Cable length | 1 m |

| Mounting Type | Screw Mount |

| Power Supply | 24 V DC |

| Output Signal | 4-20 mA |

| Response Frequency Range | 0.5 Hz to 10 kHz |

| Housing Material | Stainless Steel |

| IP Rating | IP 65 |

Applications

-

Industrial Machinery: Used extensively in monitoring critical machinery like motors, turbines, and compressors.

-

Power Plants: Vital in ensuring the performance of machinery in power generation and distribution.

-

Oil & Gas: Monitors equipment such as pumps, compressors, and gas turbines to prevent failure.

-

Mining: Provides valuable insights into the operational health of mining equipment under extreme conditions.

-

Manufacturing: Used in monitoring pumps, conveyors, and other essential machines to maintain operational efficiency.

Product Advantages

-

Enhanced Safety: Early fault detection helps prevent machinery failures, reducing the risk of accidents and improving worker safety.

-

Cost-Effective Maintenance: By detecting issues early, the need for expensive repairs and unplanned downtime is minimized.

-

Increased Equipment Lifespan: Regular monitoring extends the life of machinery by allowing for timely interventions.

-

Real-Time Data: Continuous data collection ensures that operators always have up-to-date information to make informed decisions.

-

Reduced Downtime: Minimizes production interruptions by enabling predictive maintenance rather than reactive repairs.

-

Versatile Use: Suitable for a wide range of industries, from energy production to manufacturing.

FAQs

Q1: What type of vibration faults can the Bently Nevada 330703-000-060-10-02-00 sensor detect?

A1: This sensor can detect a wide range of vibration faults including imbalance, misalignment, bearing defects, and looseness, which can be critical indicators of machinery failure.

Q2: Is the 330703-000-060-10-02-00 sensor compatible with other Bently Nevada systems?

A2: Yes, it is fully compatible with other Bently Nevada monitoring systems and can be integrated into larger machinery protection and monitoring setups.

Q3: What is the operating temperature range of this sensor?

A3: The operating temperature range is from -40°C to +85°C, making it suitable for harsh industrial environments.

Q4: How does this sensor help with predictive maintenance?

A4: The sensor provides real-time vibration data that can be analyzed to identify early signs of wear and damage, allowing maintenance teams to act before costly repairs are needed.

Q5: Can the sensor output be remotely monitored?

A5: Yes, the sensor is compatible with Bently Nevada’s remote monitoring systems, allowing operators to monitor machinery conditions remotely.

Q6: What type of output signal does the sensor provide?

A6: The sensor provides a 4-20 mA output signal, which can be easily integrated into various control systems.

Q7: Is the sensor resistant to environmental factors?

A7: Yes, the sensor has an IP 65 rating, making it resistant to dust and water ingress, suitable for industrial environments.

Q8: What kind of mounting does this sensor require?

A8: The sensor is designed for screw mounting, ensuring secure attachment to the monitored equipment.

Q9: What is the weight of the sensor?

A9: The weight of the sensor is 0.255kg.

Q10: What is the maximum vibration range that the sensor can measure?

A10: The sensor can measure vibrations ranging from 0.01 to 50 g, covering a wide spectrum of machinery operating conditions.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...