Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

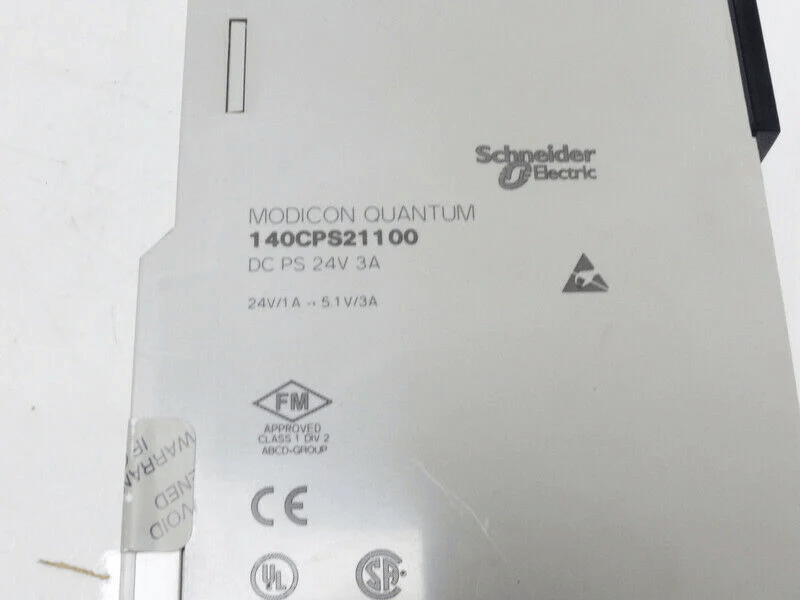

Schneider 170AEC92000 High Speed Counter Module Base

Manufacturer:Schneider

Product Number:170AEC92000

Product Type:High Speed Counter Module Base

Origin:France

Dimensions:47.5 × 125 × 141.5 mm

Weight:0.21 kg

Views:79

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Schneider Electric 170AEC92000 is a High-Speed Counter Module Base designed for use in the Modicon Momentum automation platform. It serves as an essential interface for counting high-speed pulses from various input devices such as encoders, proximity sensors, and pulse generators. Built to handle applications requiring real-time response and deterministic control, this module is tailored for demanding environments in industrial automation.

The 170AEC92000 module integrates seamlessly into the Momentum I/O architecture, providing reliable high-speed counting capabilities with minimal latency. Its robust design ensures it can operate effectively in harsh conditions, including environments with electromagnetic interference and temperature extremes.

Product Specifications

| Parameter | Details |

|---|---|

| Product Name | Schneider 170AEC92000 High-Speed Counter Module Base |

| Manufacturer | Schneider Electric |

| Product Series | Modicon Momentum |

| Function | High-Speed Counter Module Base |

| Input Type | Differential or Single-ended (depending on wiring) |

| Counting Frequency | Up to 1 MHz (depending on wiring and configuration) |

| Channels Supported | Typically supports 2 to 4 channels |

| Counter Modes | Quadrature, Up/Down, Pulse/Direction, Frequency |

| Backplane Compatibility | Momentum I/O Base |

| Voltage Range | 24 VDC (nominal, for logic and I/O signals) |

| Power Consumption | Approx. 1.5 W |

| Operating Temperature | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature | -40°C to 85°C |

| Mounting Type | DIN rail or panel-mounted (with base) |

| Dimensions (W x H x D) | 47.5 × 125 × 141.5 mm |

| Weight | 0.21 kg |

| Certifications | CE, UL, CSA, RoHS compliant |

| Communication Port | Interfaces with the Momentum processor via I/O base |

Applications

The 170AEC92000 is used in industries that require high-speed counting and precision motion control, including but not limited to:

-

Packaging Automation – Tracking and counting items at high speed on production lines.

-

Conveyor Systems – Monitoring encoder feedback for motor speed and position control.

-

Textile Machinery – Counting yarn feed rates and spindle rotations in real-time.

-

Material Handling Systems – Coordinating robotic arms and motors via precise count inputs.

-

Printing Industry – Counting print cycles and synchronizing paper feed mechanisms.

-

Food and Beverage Industry – Synchronizing bottling, capping, and packaging systems.

Product Advantages

-

Real-Time Processing: Handles up to 1 MHz input rates, suitable for high-speed industrial operations.

-

Flexible Counting Modes: Supports multiple counting modes such as quadrature and pulse/direction for versatile applications.

-

Compact Design: Space-efficient footprint allows for easy installation in control cabinets.

-

Robust Integration: Seamless compatibility with Momentum PLC systems ensures smooth I/O communication.

-

Energy Efficient: Low power consumption suitable for green automation systems.

-

High Reliability: Built for continuous 24/7 industrial use with high immunity to electrical noise.

-

Easy Maintenance: Designed for hot-swapping and modular replacements in operational environments.

Frequently Asked Questions (FAQ)

-

What is the maximum counting frequency supported by the 170AEC92000?

The module can count pulses at rates up to 1 MHz depending on the input configuration.

-

Can the 170AEC92000 module be used with incremental encoders?

Yes, it supports quadrature encoder input with A/B signals for direction detection.

-

Does the module require external power for operation?

It operates via the Momentum I/O base with nominal 24 VDC for signal conditioning.

-

What type of outputs does this module provide?

The module primarily functions as an input counter; it processes pulse signals from external sources.

-

Is it hot-swappable during operation?

Yes, Schneider’s Momentum platform supports hot-swapping of I/O modules with proper configuration.

-

Which control system is this module compatible with?

It is designed for use within Schneider’s Modicon Momentum PLC systems.

-

What is the environmental protection rating of the module?

While it doesn’t have an IP rating itself, it can be installed in protected industrial enclosures.

-

Can it be used in motion control applications?

Yes, it’s commonly used in motion tracking and speed feedback applications via encoders.

-

How many counters are available in this module?

It supports multiple (typically 2 to 4) independent high-speed counter channels.

-

Is software configuration required?

Yes, the module should be configured via Schneider’s Unity Pro or EcoStruxure software tools.

Schneider 170AEC92000 High Speed Counter Module Base

Manufacturer:Schneider

Product Number:170AEC92000

Product Type:High Speed Counter Module Base

Origin:France

Dimensions:47.5 × 125 × 141.5 mm

Weight:0.21 kg

Views:79

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Schneider Electric 170AEC92000 is a High-Speed Counter Module Base designed for use in the Modicon Momentum automation platform. It serves as an essential interface for counting high-speed pulses from various input devices such as encoders, proximity sensors, and pulse generators. Built to handle applications requiring real-time response and deterministic control, this module is tailored for demanding environments in industrial automation.

The 170AEC92000 module integrates seamlessly into the Momentum I/O architecture, providing reliable high-speed counting capabilities with minimal latency. Its robust design ensures it can operate effectively in harsh conditions, including environments with electromagnetic interference and temperature extremes.

Product Specifications

| Parameter | Details |

|---|---|

| Product Name | Schneider 170AEC92000 High-Speed Counter Module Base |

| Manufacturer | Schneider Electric |

| Product Series | Modicon Momentum |

| Function | High-Speed Counter Module Base |

| Input Type | Differential or Single-ended (depending on wiring) |

| Counting Frequency | Up to 1 MHz (depending on wiring and configuration) |

| Channels Supported | Typically supports 2 to 4 channels |

| Counter Modes | Quadrature, Up/Down, Pulse/Direction, Frequency |

| Backplane Compatibility | Momentum I/O Base |

| Voltage Range | 24 VDC (nominal, for logic and I/O signals) |

| Power Consumption | Approx. 1.5 W |

| Operating Temperature | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature | -40°C to 85°C |

| Mounting Type | DIN rail or panel-mounted (with base) |

| Dimensions (W x H x D) | 47.5 × 125 × 141.5 mm |

| Weight | 0.21 kg |

| Certifications | CE, UL, CSA, RoHS compliant |

| Communication Port | Interfaces with the Momentum processor via I/O base |

Applications

The 170AEC92000 is used in industries that require high-speed counting and precision motion control, including but not limited to:

-

Packaging Automation – Tracking and counting items at high speed on production lines.

-

Conveyor Systems – Monitoring encoder feedback for motor speed and position control.

-

Textile Machinery – Counting yarn feed rates and spindle rotations in real-time.

-

Material Handling Systems – Coordinating robotic arms and motors via precise count inputs.

-

Printing Industry – Counting print cycles and synchronizing paper feed mechanisms.

-

Food and Beverage Industry – Synchronizing bottling, capping, and packaging systems.

Product Advantages

-

Real-Time Processing: Handles up to 1 MHz input rates, suitable for high-speed industrial operations.

-

Flexible Counting Modes: Supports multiple counting modes such as quadrature and pulse/direction for versatile applications.

-

Compact Design: Space-efficient footprint allows for easy installation in control cabinets.

-

Robust Integration: Seamless compatibility with Momentum PLC systems ensures smooth I/O communication.

-

Energy Efficient: Low power consumption suitable for green automation systems.

-

High Reliability: Built for continuous 24/7 industrial use with high immunity to electrical noise.

-

Easy Maintenance: Designed for hot-swapping and modular replacements in operational environments.

Frequently Asked Questions (FAQ)

-

What is the maximum counting frequency supported by the 170AEC92000?

The module can count pulses at rates up to 1 MHz depending on the input configuration.

-

Can the 170AEC92000 module be used with incremental encoders?

Yes, it supports quadrature encoder input with A/B signals for direction detection.

-

Does the module require external power for operation?

It operates via the Momentum I/O base with nominal 24 VDC for signal conditioning.

-

What type of outputs does this module provide?

The module primarily functions as an input counter; it processes pulse signals from external sources.

-

Is it hot-swappable during operation?

Yes, Schneider’s Momentum platform supports hot-swapping of I/O modules with proper configuration.

-

Which control system is this module compatible with?

It is designed for use within Schneider’s Modicon Momentum PLC systems.

-

What is the environmental protection rating of the module?

While it doesn’t have an IP rating itself, it can be installed in protected industrial enclosures.

-

Can it be used in motion control applications?

Yes, it’s commonly used in motion tracking and speed feedback applications via encoders.

-

How many counters are available in this module?

It supports multiple (typically 2 to 4) independent high-speed counter channels.

-

Is software configuration required?

Yes, the module should be configured via Schneider’s Unity Pro or EcoStruxure software tools.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...