Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

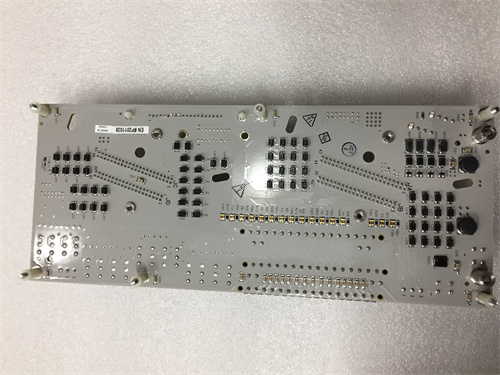

Honeywell 900C30S-0360-00 HC900 C30 Controller CPU

Manufacturer:Honeywell

Product Number:900C30S-0360-00

Product Type:HC900 C30 Controller CPU

Origin:USA

Dimensions:120 × 45 × 100 mm

Weight:0.85 kg

Views:49

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell 900C30S-0360-00 is a HC900 C30 Controller CPU, specifically designed for high-performance process automation in a wide range of industrial environments. As part of Honeywell’s HC900 Hybrid Controller series, the C30 model stands out for its compact, modular design, scalable architecture, and extensive communication support, making it suitable for both process and safety applications.

Engineered to handle complex control strategies, the 900C30S-0360-00 combines powerful processing capabilities with flexibility and reliability. It integrates seamlessly with I/O modules and operator interface solutions, and is widely used in industries such as chemical, water treatment, food & beverage, and thermal processing.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 900C30S-0360-00 |

| Product Type | Controller CPU (C30) |

| Series | HC900 Hybrid Control System |

| CPU Type | C30 Single CPU |

| Memory | 10 MB non-volatile memory |

| Number of I/O Loops | Supports up to 960 I/O points |

| Scan Rate | 25 ms typical per 100 PID loops |

| Programming Interface | Ethernet (Modbus/TCP, peer-to-peer, HMI comms) |

| Programming Software | Hybrid Control Designer |

| Communication Ports | 1 x Ethernet, 1 x RS485/Modbus, 1 x RS232 |

| Redundancy Support | No (only supported in C70 variants) |

| Operating Temperature | 0°C to 60°C |

| Power Supply | 24 VDC |

| Mounting Type | DIN Rail |

| Dimensions (HxWxD) | 120 × 45 × 100 mm |

| Weight | 0.85 kg |

| Certifications | CE, UL, CSA, FM (Class 1, Div 2), ATEX Zone 2 |

Product Applications

The Honeywell 900C30S-0360-00 is utilized across various industrial sectors for applications that require high control reliability and performance:

-

Thermal Processing Systems – Kilns, furnaces, and ovens requiring precise temperature control

-

Water & Wastewater Treatment – Pump control, tank level monitoring, and flow regulation

-

Pharmaceutical & Chemical Processing – Batch control, mixing, and reaction control

-

Food & Beverage Industry – CIP/SIP control, pasteurization, and recipe management

-

Environmental Systems – Air emissions, pollution monitoring, and compliance control

-

Power Plants & Boilers – Steam loop management, fuel feed, and safety interlocks

Product Advantages

-

Compact and Modular Design

The C30’s small footprint allows for easy installation in tight enclosures without sacrificing scalability.

-

High-Speed Processing

Offers fast loop execution for complex control tasks, supporting up to 960 I/O points.

-

Flexible Communication Options

Equipped with Ethernet and serial ports, allowing seamless integration into SCADA and DCS systems.

-

Enhanced Reliability

Industrial-grade hardware with wide temperature tolerance and compliance with global safety standards.

-

User-Friendly Engineering Tools

Comes with Honeywell’s Hybrid Control Designer software for intuitive programming, debugging, and commissioning.

-

Seamless Integration with Experion

Easily connects to Honeywell’s Experion HS/PKS platforms for supervisory control and data acquisition.

Frequently Asked Questions (FAQ)

-

Q: What is the main use of the 900C30S-0360-00 controller?

A: It is primarily used for hybrid process control in systems requiring analog, digital, and thermal control in industrial environments.

-

Q: Can this controller be used for safety applications?

A: No, the C30 CPU is not TUV certified for SIL-rated safety; consider the HC900 Safety versions for such needs.

-

Q: Is it possible to expand I/O modules?

A: Yes, the C30 supports modular I/O expansion via the HC900 rack system.

-

Q: What software is used for configuration?

A: Configuration and programming are done using Hybrid Control Designer (HCD).

-

Q: Does the C30 support redundant CPUs?

A: No, redundancy is not supported on the C30; consider the C70 variant for redundant CPU architecture.

-

Q: Is the controller suitable for high-vibration environments?

A: It complies with industrial standards but should be housed in vibration-protected enclosures for extreme conditions.

-

Q: What types of communication protocols are supported?

A: The C30 supports Modbus TCP, Modbus RTU, and peer-to-peer Ethernet communication.

-

Q: Can it be used in hazardous environments?

A: Yes, the controller is rated for Class 1, Div 2 and ATEX Zone 2 environments with proper installation.

-

Q: What kind of power does it require?

A: It operates with a 24 VDC power supply.

-

Q: How is the firmware updated?

A: Firmware can be updated via USB or Ethernet through the HCD software with the appropriate Honeywell tools.

Honeywell 900C30S-0360-00 HC900 C30 Controller CPU

Manufacturer:Honeywell

Product Number:900C30S-0360-00

Product Type:HC900 C30 Controller CPU

Origin:USA

Dimensions:120 × 45 × 100 mm

Weight:0.85 kg

Views:49

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell 900C30S-0360-00 is a HC900 C30 Controller CPU, specifically designed for high-performance process automation in a wide range of industrial environments. As part of Honeywell’s HC900 Hybrid Controller series, the C30 model stands out for its compact, modular design, scalable architecture, and extensive communication support, making it suitable for both process and safety applications.

Engineered to handle complex control strategies, the 900C30S-0360-00 combines powerful processing capabilities with flexibility and reliability. It integrates seamlessly with I/O modules and operator interface solutions, and is widely used in industries such as chemical, water treatment, food & beverage, and thermal processing.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 900C30S-0360-00 |

| Product Type | Controller CPU (C30) |

| Series | HC900 Hybrid Control System |

| CPU Type | C30 Single CPU |

| Memory | 10 MB non-volatile memory |

| Number of I/O Loops | Supports up to 960 I/O points |

| Scan Rate | 25 ms typical per 100 PID loops |

| Programming Interface | Ethernet (Modbus/TCP, peer-to-peer, HMI comms) |

| Programming Software | Hybrid Control Designer |

| Communication Ports | 1 x Ethernet, 1 x RS485/Modbus, 1 x RS232 |

| Redundancy Support | No (only supported in C70 variants) |

| Operating Temperature | 0°C to 60°C |

| Power Supply | 24 VDC |

| Mounting Type | DIN Rail |

| Dimensions (HxWxD) | 120 × 45 × 100 mm |

| Weight | 0.85 kg |

| Certifications | CE, UL, CSA, FM (Class 1, Div 2), ATEX Zone 2 |

Product Applications

The Honeywell 900C30S-0360-00 is utilized across various industrial sectors for applications that require high control reliability and performance:

-

Thermal Processing Systems – Kilns, furnaces, and ovens requiring precise temperature control

-

Water & Wastewater Treatment – Pump control, tank level monitoring, and flow regulation

-

Pharmaceutical & Chemical Processing – Batch control, mixing, and reaction control

-

Food & Beverage Industry – CIP/SIP control, pasteurization, and recipe management

-

Environmental Systems – Air emissions, pollution monitoring, and compliance control

-

Power Plants & Boilers – Steam loop management, fuel feed, and safety interlocks

Product Advantages

-

Compact and Modular Design

The C30’s small footprint allows for easy installation in tight enclosures without sacrificing scalability.

-

High-Speed Processing

Offers fast loop execution for complex control tasks, supporting up to 960 I/O points.

-

Flexible Communication Options

Equipped with Ethernet and serial ports, allowing seamless integration into SCADA and DCS systems.

-

Enhanced Reliability

Industrial-grade hardware with wide temperature tolerance and compliance with global safety standards.

-

User-Friendly Engineering Tools

Comes with Honeywell’s Hybrid Control Designer software for intuitive programming, debugging, and commissioning.

-

Seamless Integration with Experion

Easily connects to Honeywell’s Experion HS/PKS platforms for supervisory control and data acquisition.

Frequently Asked Questions (FAQ)

-

Q: What is the main use of the 900C30S-0360-00 controller?

A: It is primarily used for hybrid process control in systems requiring analog, digital, and thermal control in industrial environments.

-

Q: Can this controller be used for safety applications?

A: No, the C30 CPU is not TUV certified for SIL-rated safety; consider the HC900 Safety versions for such needs.

-

Q: Is it possible to expand I/O modules?

A: Yes, the C30 supports modular I/O expansion via the HC900 rack system.

-

Q: What software is used for configuration?

A: Configuration and programming are done using Hybrid Control Designer (HCD).

-

Q: Does the C30 support redundant CPUs?

A: No, redundancy is not supported on the C30; consider the C70 variant for redundant CPU architecture.

-

Q: Is the controller suitable for high-vibration environments?

A: It complies with industrial standards but should be housed in vibration-protected enclosures for extreme conditions.

-

Q: What types of communication protocols are supported?

A: The C30 supports Modbus TCP, Modbus RTU, and peer-to-peer Ethernet communication.

-

Q: Can it be used in hazardous environments?

A: Yes, the controller is rated for Class 1, Div 2 and ATEX Zone 2 environments with proper installation.

-

Q: What kind of power does it require?

A: It operates with a 24 VDC power supply.

-

Q: How is the firmware updated?

A: Firmware can be updated via USB or Ethernet through the HCD software with the appropriate Honeywell tools.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...