Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

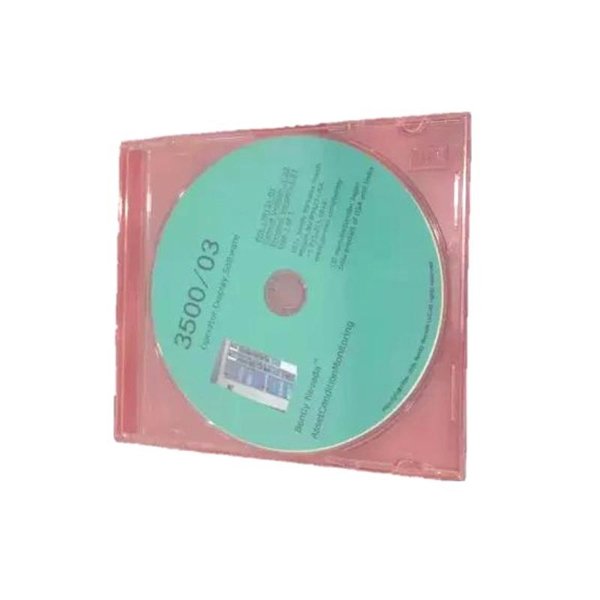

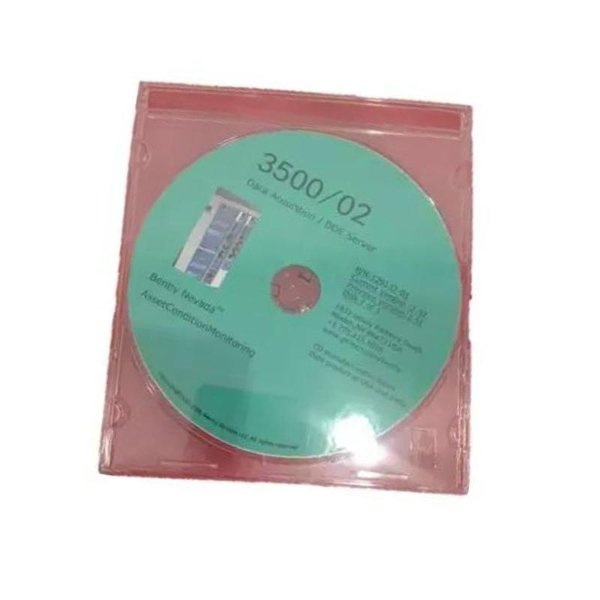

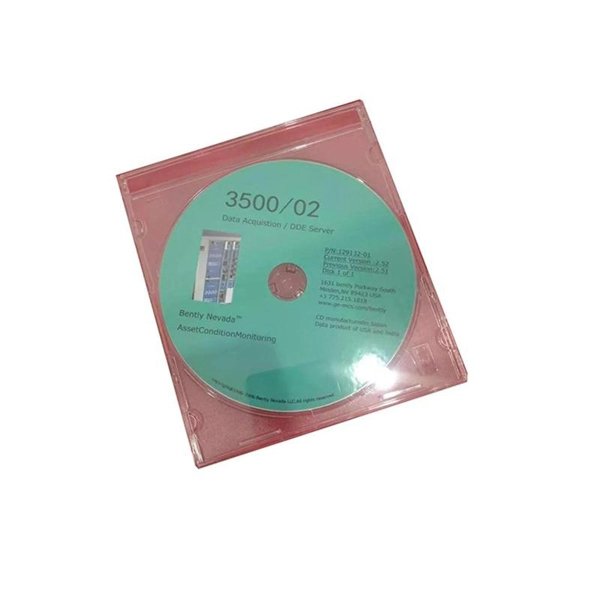

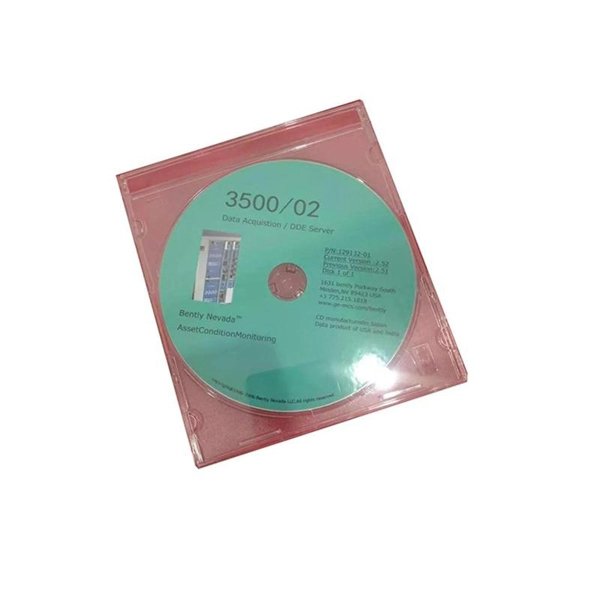

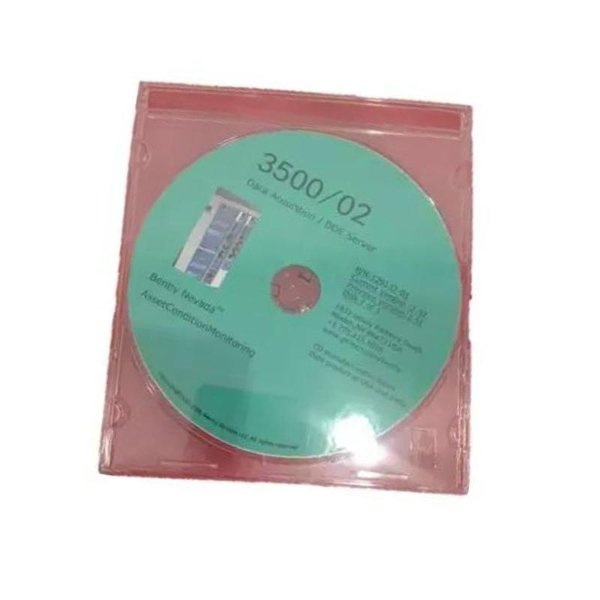

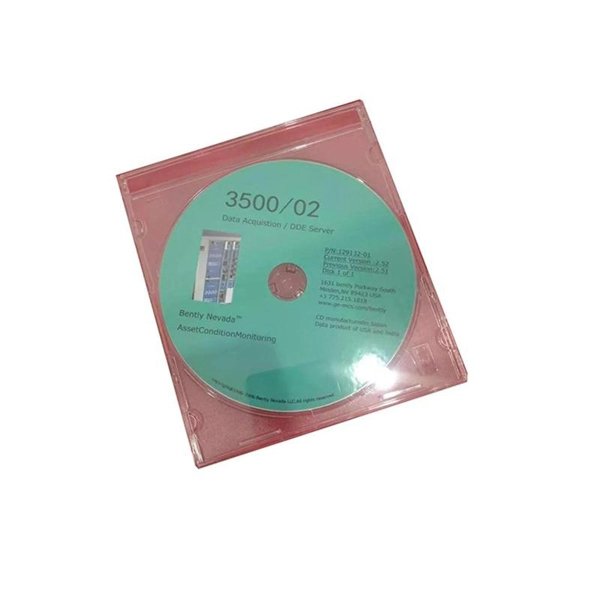

Bently Nevada 3500/02 129133-02 Rack Configuration Software

Manufacturer:Bently Nevada

Product Number:3500/02 129133-02

Product Type:Rack Configuration Software

Origin:USA

Dimensions:Please ask customer service

Shipping weight:0.5 kg

Views:46

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/02 129133-02 rack configuration software is a critical tool designed for configuring, managing, and optimizing Bently Nevada’s 3500 series machinery monitoring system. This software simplifies the setup process of condition monitoring racks, enabling users to quickly and accurately integrate sensors, set parameters, and perform routine diagnostics. It is a valuable asset for industries that rely on continuous monitoring of machine health, such as power plants, oil and gas, and manufacturing.

With its intuitive user interface, the 3500/02 software streamlines system configuration, including sensor calibration, alarm settings, and data visualization. By automating the setup of vibration, temperature, and proximity sensors, the software helps reduce human error, enhances reliability, and ensures that systems operate at peak efficiency.

As a result, this software is indispensable for industries that rely on machinery protection and predictive maintenance. It ensures operators can maintain optimal system performance while preventing downtime due to unnoticed machine failure.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | 3500/02 129133-02 |

| Brand | Bently Nevada |

| Product Type | Rack Configuration Software |

| Shipping Weight | 0.5 kg |

| Dimensions | Please contact customer service for dimensions |

| Compatible System | Bently Nevada 3500 Series |

| Software Requirements | PC with Windows OS (specific version details available upon request) |

| Interface | Graphical User Interface (GUI) |

| License | Software license for one configuration system |

| Application | Industrial Machinery Condition Monitoring |

| Installation | Easy installation via downloadable package |

| Security | Password-protected access for configuration |

Applications

-

Condition Monitoring Systems

The 3500/02 software is primarily used to configure and manage Bently Nevada’s 3500 condition monitoring racks. It allows for seamless integration of vibration, temperature, and other industrial sensors, ensuring accurate data collection and machinery health monitoring in real-time.

-

Machinery Protection

This software is essential for machinery protection, as it enables operators to set alarm thresholds, monitor machinery health, and take preventive actions before faults escalate into costly failures. The ability to customize alarm settings ensures that only critical changes trigger alerts, preventing unnecessary downtime.

-

Power Generation

In power plants, the 3500/02 software plays a key role in monitoring turbines, pumps, and other critical equipment. It ensures that any deviations from normal operating conditions are identified promptly, preventing unplanned outages and extending the life of expensive equipment.

-

Oil & Gas Industry

The software is used in oil and gas facilities to monitor rotating equipment such as pumps, compressors, and motors. It helps detect mechanical issues at an early stage, minimizing the risk of catastrophic failure and reducing maintenance costs.

-

Manufacturing and Heavy Industry

This software is widely used in manufacturing plants to optimize the monitoring of industrial machinery. By configuring vibration and temperature sensors, operators can improve operational efficiency and extend the life of production equipment.

-

Mining

The 3500/02 configuration software is also used in mining operations to monitor crushers, mills, and other heavy-duty machinery. It ensures that any mechanical issues are detected early, preventing system breakdowns that could result in costly downtime.

Advantages

-

Efficient System Setup

The 3500/02 software allows for fast and efficient configuration of Bently Nevada’s 3500 monitoring system. By automating many setup tasks, it reduces the amount of time required to configure vibration sensors and other monitoring equipment.

-

Real-Time Monitoring and Alerts

The software allows users to monitor machine conditions in real time. Operators receive alerts when machines deviate from expected performance parameters, allowing for quick intervention and preventing damage to critical machinery.

-

Reduced Risk of Human Error

With its intuitive interface and automated configuration, the software minimizes the likelihood of human error in the setup process, ensuring that sensor data is accurately collected and the system is correctly configured.

-

Customizable Alerts and Thresholds

Users can easily customize alarm thresholds for different sensors, ensuring that the system responds to significant changes in machine health while filtering out irrelevant data.

-

Comprehensive Reporting

The software generates detailed reports on machinery condition, sensor performance, and system status, which can be used for trend analysis, predictive maintenance, and historical recordkeeping.

-

Scalability

The 3500/02 software is scalable, making it suitable for both small systems with a few sensors and large industrial setups with hundreds of monitoring points. This flexibility ensures that it can meet the needs of a wide range of applications.

FAQs

Q1: What is the primary purpose of the Bently Nevada 3500/02 129133-02 rack configuration software?

A1: The primary purpose of this software is to configure and manage Bently Nevada’s 3500 monitoring racks, enabling the seamless integration and operation of vibration, temperature, and proximity sensors in machinery health monitoring systems.

Q2: What is the shipping weight of this software?

A2: The shipping weight of the software is 0.5 kg.

Q3: What operating systems are supported by the 3500/02 configuration software?

A3: The software is compatible with PCs running specific versions of the Windows operating system. For details on system requirements, please contact Bently Nevada or refer to the user manual.

Q4: Can the 3500/02 software be used to monitor multiple racks?

A4: Yes, the software supports the configuration and monitoring of multiple racks, making it ideal for larger industrial setups.

Q5: Is the software compatible with all Bently Nevada sensors?

A5: Yes, the software is compatible with a wide range of Bently Nevada sensors, including vibration, temperature, and proximity sensors.

Q6: Can the software be used for predictive maintenance?

A6: Yes, the 3500/02 software enables predictive maintenance by providing real-time data, alarms, and reports on machinery health, allowing operators to take proactive actions.

Q7: How does the software improve system efficiency?

A7: By automating system configuration and offering real-time monitoring and alerts, the software ensures that machines operate within optimal parameters, reducing downtime and improving operational efficiency.

Q8: Is this software easy to install?

A8: Yes, the software is easy to install via a downloadable package, and detailed instructions are provided to guide users through the installation process.

Q9: Does the software require a license?

A9: Yes, the software is licensed for use on a single configuration system, ensuring that users have the appropriate rights for installation and operation.

Q10: What industries use the Bently Nevada 3500/02 configuration software?

A10: The software is used in a variety of industries, including power generation, oil and gas, manufacturing, mining, and heavy industry, where machinery health and predictive maintenance are critical.

Bently Nevada 3500/02 129133-02 Rack Configuration Software

Manufacturer:Bently Nevada

Product Number:3500/02 129133-02

Product Type:Rack Configuration Software

Origin:USA

Dimensions:Please ask customer service

Shipping weight:0.5 kg

Views:46

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/02 129133-02 rack configuration software is a critical tool designed for configuring, managing, and optimizing Bently Nevada’s 3500 series machinery monitoring system. This software simplifies the setup process of condition monitoring racks, enabling users to quickly and accurately integrate sensors, set parameters, and perform routine diagnostics. It is a valuable asset for industries that rely on continuous monitoring of machine health, such as power plants, oil and gas, and manufacturing.

With its intuitive user interface, the 3500/02 software streamlines system configuration, including sensor calibration, alarm settings, and data visualization. By automating the setup of vibration, temperature, and proximity sensors, the software helps reduce human error, enhances reliability, and ensures that systems operate at peak efficiency.

As a result, this software is indispensable for industries that rely on machinery protection and predictive maintenance. It ensures operators can maintain optimal system performance while preventing downtime due to unnoticed machine failure.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | 3500/02 129133-02 |

| Brand | Bently Nevada |

| Product Type | Rack Configuration Software |

| Shipping Weight | 0.5 kg |

| Dimensions | Please contact customer service for dimensions |

| Compatible System | Bently Nevada 3500 Series |

| Software Requirements | PC with Windows OS (specific version details available upon request) |

| Interface | Graphical User Interface (GUI) |

| License | Software license for one configuration system |

| Application | Industrial Machinery Condition Monitoring |

| Installation | Easy installation via downloadable package |

| Security | Password-protected access for configuration |

Applications

-

Condition Monitoring Systems

The 3500/02 software is primarily used to configure and manage Bently Nevada’s 3500 condition monitoring racks. It allows for seamless integration of vibration, temperature, and other industrial sensors, ensuring accurate data collection and machinery health monitoring in real-time.

-

Machinery Protection

This software is essential for machinery protection, as it enables operators to set alarm thresholds, monitor machinery health, and take preventive actions before faults escalate into costly failures. The ability to customize alarm settings ensures that only critical changes trigger alerts, preventing unnecessary downtime.

-

Power Generation

In power plants, the 3500/02 software plays a key role in monitoring turbines, pumps, and other critical equipment. It ensures that any deviations from normal operating conditions are identified promptly, preventing unplanned outages and extending the life of expensive equipment.

-

Oil & Gas Industry

The software is used in oil and gas facilities to monitor rotating equipment such as pumps, compressors, and motors. It helps detect mechanical issues at an early stage, minimizing the risk of catastrophic failure and reducing maintenance costs.

-

Manufacturing and Heavy Industry

This software is widely used in manufacturing plants to optimize the monitoring of industrial machinery. By configuring vibration and temperature sensors, operators can improve operational efficiency and extend the life of production equipment.

-

Mining

The 3500/02 configuration software is also used in mining operations to monitor crushers, mills, and other heavy-duty machinery. It ensures that any mechanical issues are detected early, preventing system breakdowns that could result in costly downtime.

Advantages

-

Efficient System Setup

The 3500/02 software allows for fast and efficient configuration of Bently Nevada’s 3500 monitoring system. By automating many setup tasks, it reduces the amount of time required to configure vibration sensors and other monitoring equipment.

-

Real-Time Monitoring and Alerts

The software allows users to monitor machine conditions in real time. Operators receive alerts when machines deviate from expected performance parameters, allowing for quick intervention and preventing damage to critical machinery.

-

Reduced Risk of Human Error

With its intuitive interface and automated configuration, the software minimizes the likelihood of human error in the setup process, ensuring that sensor data is accurately collected and the system is correctly configured.

-

Customizable Alerts and Thresholds

Users can easily customize alarm thresholds for different sensors, ensuring that the system responds to significant changes in machine health while filtering out irrelevant data.

-

Comprehensive Reporting

The software generates detailed reports on machinery condition, sensor performance, and system status, which can be used for trend analysis, predictive maintenance, and historical recordkeeping.

-

Scalability

The 3500/02 software is scalable, making it suitable for both small systems with a few sensors and large industrial setups with hundreds of monitoring points. This flexibility ensures that it can meet the needs of a wide range of applications.

FAQs

Q1: What is the primary purpose of the Bently Nevada 3500/02 129133-02 rack configuration software?

A1: The primary purpose of this software is to configure and manage Bently Nevada’s 3500 monitoring racks, enabling the seamless integration and operation of vibration, temperature, and proximity sensors in machinery health monitoring systems.

Q2: What is the shipping weight of this software?

A2: The shipping weight of the software is 0.5 kg.

Q3: What operating systems are supported by the 3500/02 configuration software?

A3: The software is compatible with PCs running specific versions of the Windows operating system. For details on system requirements, please contact Bently Nevada or refer to the user manual.

Q4: Can the 3500/02 software be used to monitor multiple racks?

A4: Yes, the software supports the configuration and monitoring of multiple racks, making it ideal for larger industrial setups.

Q5: Is the software compatible with all Bently Nevada sensors?

A5: Yes, the software is compatible with a wide range of Bently Nevada sensors, including vibration, temperature, and proximity sensors.

Q6: Can the software be used for predictive maintenance?

A6: Yes, the 3500/02 software enables predictive maintenance by providing real-time data, alarms, and reports on machinery health, allowing operators to take proactive actions.

Q7: How does the software improve system efficiency?

A7: By automating system configuration and offering real-time monitoring and alerts, the software ensures that machines operate within optimal parameters, reducing downtime and improving operational efficiency.

Q8: Is this software easy to install?

A8: Yes, the software is easy to install via a downloadable package, and detailed instructions are provided to guide users through the installation process.

Q9: Does the software require a license?

A9: Yes, the software is licensed for use on a single configuration system, ensuring that users have the appropriate rights for installation and operation.

Q10: What industries use the Bently Nevada 3500/02 configuration software?

A10: The software is used in a variety of industries, including power generation, oil and gas, manufacturing, mining, and heavy industry, where machinery health and predictive maintenance are critical.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...