Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

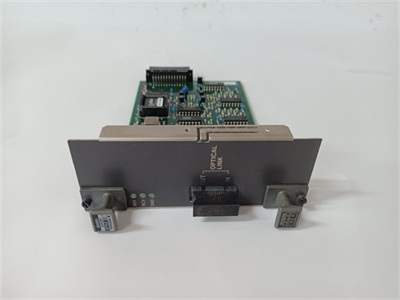

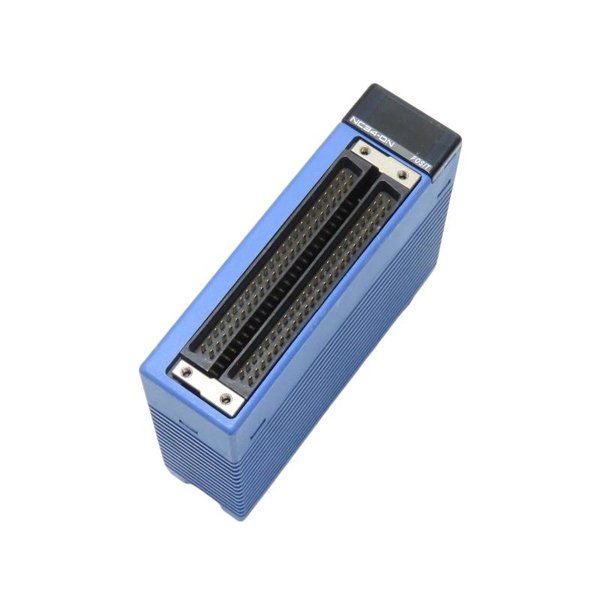

Yokogawa F3NC34-0N Positioning Module

Manufacturer:Yokogawa

Product Number:F3NC34-0N

Product Type:Positioning Module

Origin:Japan

Dimensions:28.9 x 100 x 83.2 mm

Weight:0.18 kg

Views:37

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa F3NC34-0N Positioning Module is a high-performance motion control component designed to deliver precise positioning for industrial automation systems. This module belongs to the Yokogawa FA-M3 series and is used to manage and control servo and stepper motors in applications that require accurate motion control. By integrating advanced motion control functions and communication capabilities, the F3NC34-0N enhances machine efficiency and reduces system downtime.

Engineered for reliability and precision, the module ensures high-speed data processing, smooth motor operation, and flexible configuration. Its design supports synchronization and advanced positioning algorithms, making it ideal for demanding environments where accuracy and responsiveness are critical.

Product Specifications

| Parameter | Details |

|---|---|

| Model | Yokogawa F3NC34-0N |

| Product Type | Positioning Module |

| Control Type | Servo / Stepper Motor Control |

| Number of Control Axes | 4 axes |

| Interface Type | FA-M3 Bus |

| Positioning Method | Absolute / Incremental Encoder Feedback |

| Power Supply Voltage | 24 VDC (typical) |

| Current Consumption | Approx. 300 mA |

| Response Time | High-speed motion processing |

| Communication Protocol | FA-M3 Dedicated Protocol |

| Operating Temperature | 0°C to +55°C |

| Storage Temperature | -20°C to +75°C |

| Relative Humidity | 10%–90% (non-condensing) |

| Dimensions (H x W x D) | 28.9 x 100 x 83.2 mm |

| Weight | 0.18 kg |

Applications

The F3NC34-0N Positioning Module is widely applied in industries that require precision motion control and synchronized movement. Its common applications include:

-

CNC Machinery: For precision cutting, milling, and shaping processes.

-

Robotic Arms: To achieve accurate positioning during assembly or welding.

-

Packaging Systems: Ensuring accurate material placement in high-speed packaging lines.

-

Printing Press Machines: For precise alignment and registration control.

-

Textile Machinery: Maintaining synchronization during weaving or fabric cutting.

-

Semiconductor Manufacturing: Providing exact motion control in cleanroom environments.

Product Advantages

-

High Precision Control: Supports absolute and incremental positioning for enhanced accuracy.

-

Multi-Axis Capability: Controls up to 4 axes for complex motion applications.

-

High-Speed Processing: Optimized for real-time response, minimizing latency.

-

Reliable Performance: Built for continuous operation in industrial environments.

-

Flexible Integration: Compatible with FA-M3 series systems and modular architecture.

-

Diagnostic Functions: Advanced error detection for quick troubleshooting.

-

Compact Design: Space-saving module ideal for dense control panels.

FAQ

-

What types of motors can the F3NC34-0N control?

It supports both servo and stepper motors with compatible drivers.

-

Does it support absolute and incremental encoders?

Yes, the module can work with both absolute and incremental encoder feedback systems.

-

How many axes can this module control simultaneously?

The F3NC34-0N can control up to four independent axes.

-

Is synchronization between axes supported?

Yes, it offers synchronized control for multi-axis operations.

-

What communication protocol does it use?

It uses the FA-M3 dedicated communication protocol for real-time data exchange.

-

What is the maximum response speed for motion commands?

It supports high-speed response optimized for precision control in demanding applications.

-

Can it handle acceleration and deceleration profiles?

Yes, the module allows configuration of motion profiles for smooth transitions.

-

Does it provide alarm and fault detection?

Yes, it includes diagnostics for overcurrent, encoder errors, and communication faults.

-

Is there a software tool for configuration and tuning?

Yes, it can be configured using Yokogawa’s FA-M3 programming environment.

-

Can it integrate with PLC logic and sequences?

Absolutely, it is designed to work seamlessly with FA-M3 PLC systems.

Yokogawa F3NC34-0N Positioning Module

Manufacturer:Yokogawa

Product Number:F3NC34-0N

Product Type:Positioning Module

Origin:Japan

Dimensions:28.9 x 100 x 83.2 mm

Weight:0.18 kg

Views:37

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa F3NC34-0N Positioning Module is a high-performance motion control component designed to deliver precise positioning for industrial automation systems. This module belongs to the Yokogawa FA-M3 series and is used to manage and control servo and stepper motors in applications that require accurate motion control. By integrating advanced motion control functions and communication capabilities, the F3NC34-0N enhances machine efficiency and reduces system downtime.

Engineered for reliability and precision, the module ensures high-speed data processing, smooth motor operation, and flexible configuration. Its design supports synchronization and advanced positioning algorithms, making it ideal for demanding environments where accuracy and responsiveness are critical.

Product Specifications

| Parameter | Details |

|---|---|

| Model | Yokogawa F3NC34-0N |

| Product Type | Positioning Module |

| Control Type | Servo / Stepper Motor Control |

| Number of Control Axes | 4 axes |

| Interface Type | FA-M3 Bus |

| Positioning Method | Absolute / Incremental Encoder Feedback |

| Power Supply Voltage | 24 VDC (typical) |

| Current Consumption | Approx. 300 mA |

| Response Time | High-speed motion processing |

| Communication Protocol | FA-M3 Dedicated Protocol |

| Operating Temperature | 0°C to +55°C |

| Storage Temperature | -20°C to +75°C |

| Relative Humidity | 10%–90% (non-condensing) |

| Dimensions (H x W x D) | 28.9 x 100 x 83.2 mm |

| Weight | 0.18 kg |

Applications

The F3NC34-0N Positioning Module is widely applied in industries that require precision motion control and synchronized movement. Its common applications include:

-

CNC Machinery: For precision cutting, milling, and shaping processes.

-

Robotic Arms: To achieve accurate positioning during assembly or welding.

-

Packaging Systems: Ensuring accurate material placement in high-speed packaging lines.

-

Printing Press Machines: For precise alignment and registration control.

-

Textile Machinery: Maintaining synchronization during weaving or fabric cutting.

-

Semiconductor Manufacturing: Providing exact motion control in cleanroom environments.

Product Advantages

-

High Precision Control: Supports absolute and incremental positioning for enhanced accuracy.

-

Multi-Axis Capability: Controls up to 4 axes for complex motion applications.

-

High-Speed Processing: Optimized for real-time response, minimizing latency.

-

Reliable Performance: Built for continuous operation in industrial environments.

-

Flexible Integration: Compatible with FA-M3 series systems and modular architecture.

-

Diagnostic Functions: Advanced error detection for quick troubleshooting.

-

Compact Design: Space-saving module ideal for dense control panels.

FAQ

-

What types of motors can the F3NC34-0N control?

It supports both servo and stepper motors with compatible drivers.

-

Does it support absolute and incremental encoders?

Yes, the module can work with both absolute and incremental encoder feedback systems.

-

How many axes can this module control simultaneously?

The F3NC34-0N can control up to four independent axes.

-

Is synchronization between axes supported?

Yes, it offers synchronized control for multi-axis operations.

-

What communication protocol does it use?

It uses the FA-M3 dedicated communication protocol for real-time data exchange.

-

What is the maximum response speed for motion commands?

It supports high-speed response optimized for precision control in demanding applications.

-

Can it handle acceleration and deceleration profiles?

Yes, the module allows configuration of motion profiles for smooth transitions.

-

Does it provide alarm and fault detection?

Yes, it includes diagnostics for overcurrent, encoder errors, and communication faults.

-

Is there a software tool for configuration and tuning?

Yes, it can be configured using Yokogawa’s FA-M3 programming environment.

-

Can it integrate with PLC logic and sequences?

Absolutely, it is designed to work seamlessly with FA-M3 PLC systems.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...