Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

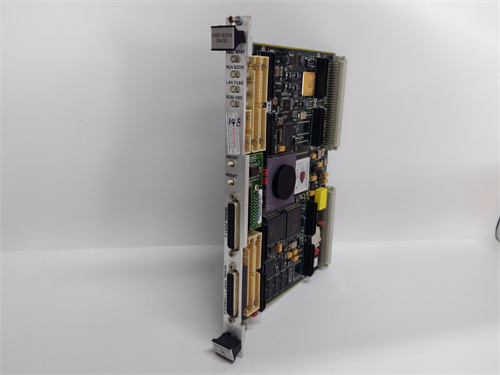

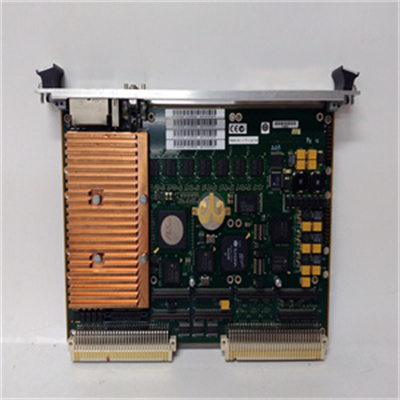

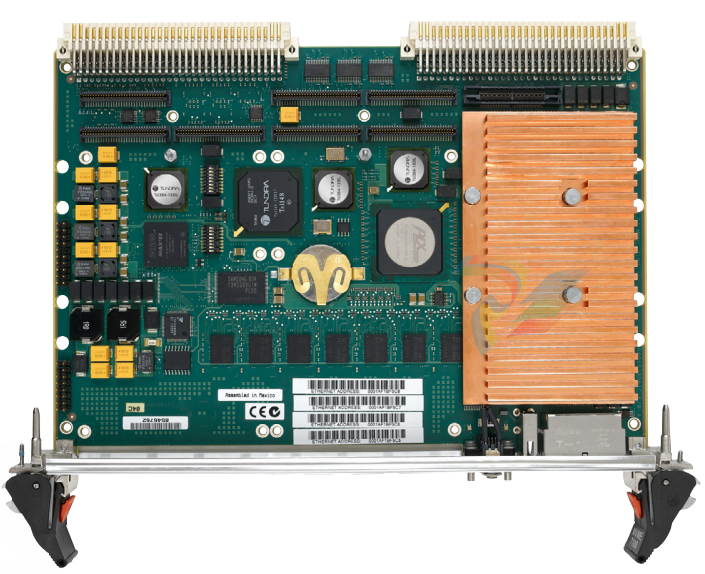

Motorola VME172PA-652SE Control Through Software

Module Number:VME172PA-652SE

Product status:Discontinued

Delivery time:In stock

Sales country:All over the world

Product situation:Brandnew , one year warranty

Product Description

VME172PA-652SE is simple and easy to master – PLC is a user oriented device, and the designer of PLC fully considers the skills and habits of on-site engineering and technical personnel. Most PLC programming provides commonly used ladder diagrams and simple instruction methods for industrial control. Programming language is visually intuitive, with few instructions and simple syntax, and does not require specialized computer knowledge and language. Personnel with certain electrical and process knowledge can master it in a short period of time. By using a dedicated programmer, it is easy to view, edit, and modify user programs.

VME172PA-652SE design, construction, and debugging cycles – when using relays and contactors to control a control project, it is necessary to first draw the electrical schematic according to the process requirements, and then draw the layout and wiring diagram of the relay screen (cabinet) for installation and debugging, which is very inconvenient to modify in the future. Using PLC control, due to its reliance on software for control, the hardware circuit is very simple, and it is a modular building block structure that has been commercialized. Therefore, only performance, capacity (input and output points, memory size) and other VME172PA-652SE need to be selected and assembled. A large amount of specific programming work can also be carried out before the arrival of the PLC, thus shortening the design cycle and allowing for simultaneous design and construction. Due to the use of software programming instead of hard wiring to achieve control functions, the heavy installation and wiring work has been greatly reduced, and the construction period has been shortened. PLC completes control tasks through programming, using user-friendly industrial programming languages, and both have mandatory and simulation functions. Therefore, the design, modification, and debugging of the program are very convenient, which can greatly shorten the design and operation cycle.

Motorola VME172PA-652SE Control Through Software

Module Number:VME172PA-652SE

Product status:Discontinued

Delivery time:In stock

Sales country:All over the world

Product situation:Brandnew , one year warranty

Product Description

VME172PA-652SE is simple and easy to master – PLC is a user oriented device, and the designer of PLC fully considers the skills and habits of on-site engineering and technical personnel. Most PLC programming provides commonly used ladder diagrams and simple instruction methods for industrial control. Programming language is visually intuitive, with few instructions and simple syntax, and does not require specialized computer knowledge and language. Personnel with certain electrical and process knowledge can master it in a short period of time. By using a dedicated programmer, it is easy to view, edit, and modify user programs.

VME172PA-652SE design, construction, and debugging cycles – when using relays and contactors to control a control project, it is necessary to first draw the electrical schematic according to the process requirements, and then draw the layout and wiring diagram of the relay screen (cabinet) for installation and debugging, which is very inconvenient to modify in the future. Using PLC control, due to its reliance on software for control, the hardware circuit is very simple, and it is a modular building block structure that has been commercialized. Therefore, only performance, capacity (input and output points, memory size) and other VME172PA-652SE need to be selected and assembled. A large amount of specific programming work can also be carried out before the arrival of the PLC, thus shortening the design cycle and allowing for simultaneous design and construction. Due to the use of software programming instead of hard wiring to achieve control functions, the heavy installation and wiring work has been greatly reduced, and the construction period has been shortened. PLC completes control tasks through programming, using user-friendly industrial programming languages, and both have mandatory and simulation functions. Therefore, the design, modification, and debugging of the program are very convenient, which can greatly shorten the design and operation cycle.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...