Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

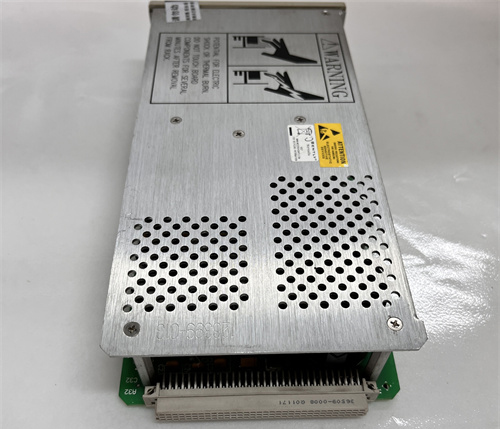

Bently Nevada 330103-00-10-10-02-05 3300 XL 8 mm Proximity Probes

Brand: Bently Nevada

Model Number:330103-00-10-10-02-05

Type:3300 XL 8 mm Proximity Probes

Product Origin: USA

Payment: T/T, Western Union, Credit Card

Weight:1480 grams

Price: USD500

Certificate: CE

Warranty: 1 years

Product Description

The Bently Nevada 330103-00-10-10-02-05 3300 XL 8 mm Proximity Probe is a sensor designed to detect the presence or motion of a target object using eddy currents. In layman’s terms, it generates an electrical signal based on its proximity to a metal surface. This makes them ideal for industrial applications requiring high precision and reliability.

Type

Eddy current proximity probe [keyword: eddy current proximity probe]

Features

- Reliable target motion detection: Provides accurate information about the position or movement of a nearby object.

- Harsh environment compatibility: Operates effectively in extreme temperatures and under heavy vibrations.

- High sensitivity: Precisely measures even small target displacements.

- Rugged construction: Built to last in demanding industrial settings.

- Easy installation and maintenance: Minimizes downtime and simplifies integration into existing systems.

Technical Specifications

- Probe diameter: 8 mm

- Operating temperature range: -40 °C to +260 °C (-40 °F to +500 °F)

- Output signal: Eddy current

- Supply voltage: 24 VDC

- Output current: 4 mA to 20 mA

- Material: Stainless steel

Bently Nevada proximity sensors are a critical component in machinery condition monitoring and protection systems, particularly in industries such as oil and gas, power generation, and manufacturing. These sensors are designed to detect the position or proximity of a target object relative to the sensor itself. They are commonly used for measuring clearances, vibrations, and shaft position in rotating machinery.

Key features and aspects of Bently Nevada proximity sensors:

- Eddy Current Principle: Bently Nevada proximity sensors often operate based on the eddy current principle. This involves generating an alternating magnetic field that induces eddy currents in a conductive target material, such as a metallic shaft or rotor. The interaction between the magnetic field and the eddy currents allows the sensor to detect changes in the target’s position or proximity.

- High Accuracy and Resolution: These sensors are known for their high accuracy and resolution, allowing them to detect even small changes in target position or clearance. This capability is crucial for monitoring the condition of rotating machinery components such as turbine blades, rotors, and bearings.

- Non-contact Operation: Bently Nevada proximity sensors operate without physical contact with the target object, which minimizes wear and tear and eliminates the risk of friction-related issues. This non-contact operation is particularly beneficial for applications where maintaining the integrity of the monitored machinery is essential.

- Robust Construction: Given the often harsh operating environments in industrial settings, Bently Nevada proximity sensors are typically designed to be rugged and durable. They can withstand extreme temperatures, high levels of vibration, and exposure to dust, moisture, and other contaminants commonly found in industrial environments.

- Various Mounting Options: These sensors may come with different mounting options to suit various installation requirements. They can be installed in a variety of configurations, including flush-mount, non-flush-mount, and externally mounted configurations, depending on the specific application and space constraints.

- Integration with Monitoring Systems: Bently Nevada proximity sensors are often integrated with comprehensive machinery condition monitoring and protection systems. The data collected by these sensors can be processed and analyzed in real-time to assess machinery health, identify potential issues, and trigger alarms or shutdowns when abnormal conditions are detected.

Bently Nevada 330103-00-10-10-02-05 3300 XL 8 mm Proximity Probes

Brand: Bently Nevada

Model Number:330103-00-10-10-02-05

Type:3300 XL 8 mm Proximity Probes

Product Origin: USA

Payment: T/T, Western Union, Credit Card

Weight:1480 grams

Price: USD500

Certificate: CE

Warranty: 1 years

Product Description

The Bently Nevada 330103-00-10-10-02-05 3300 XL 8 mm Proximity Probe is a sensor designed to detect the presence or motion of a target object using eddy currents. In layman’s terms, it generates an electrical signal based on its proximity to a metal surface. This makes them ideal for industrial applications requiring high precision and reliability.

Type

Eddy current proximity probe [keyword: eddy current proximity probe]

Features

- Reliable target motion detection: Provides accurate information about the position or movement of a nearby object.

- Harsh environment compatibility: Operates effectively in extreme temperatures and under heavy vibrations.

- High sensitivity: Precisely measures even small target displacements.

- Rugged construction: Built to last in demanding industrial settings.

- Easy installation and maintenance: Minimizes downtime and simplifies integration into existing systems.

Technical Specifications

- Probe diameter: 8 mm

- Operating temperature range: -40 °C to +260 °C (-40 °F to +500 °F)

- Output signal: Eddy current

- Supply voltage: 24 VDC

- Output current: 4 mA to 20 mA

- Material: Stainless steel

Bently Nevada proximity sensors are a critical component in machinery condition monitoring and protection systems, particularly in industries such as oil and gas, power generation, and manufacturing. These sensors are designed to detect the position or proximity of a target object relative to the sensor itself. They are commonly used for measuring clearances, vibrations, and shaft position in rotating machinery.

Key features and aspects of Bently Nevada proximity sensors:

- Eddy Current Principle: Bently Nevada proximity sensors often operate based on the eddy current principle. This involves generating an alternating magnetic field that induces eddy currents in a conductive target material, such as a metallic shaft or rotor. The interaction between the magnetic field and the eddy currents allows the sensor to detect changes in the target’s position or proximity.

- High Accuracy and Resolution: These sensors are known for their high accuracy and resolution, allowing them to detect even small changes in target position or clearance. This capability is crucial for monitoring the condition of rotating machinery components such as turbine blades, rotors, and bearings.

- Non-contact Operation: Bently Nevada proximity sensors operate without physical contact with the target object, which minimizes wear and tear and eliminates the risk of friction-related issues. This non-contact operation is particularly beneficial for applications where maintaining the integrity of the monitored machinery is essential.

- Robust Construction: Given the often harsh operating environments in industrial settings, Bently Nevada proximity sensors are typically designed to be rugged and durable. They can withstand extreme temperatures, high levels of vibration, and exposure to dust, moisture, and other contaminants commonly found in industrial environments.

- Various Mounting Options: These sensors may come with different mounting options to suit various installation requirements. They can be installed in a variety of configurations, including flush-mount, non-flush-mount, and externally mounted configurations, depending on the specific application and space constraints.

- Integration with Monitoring Systems: Bently Nevada proximity sensors are often integrated with comprehensive machinery condition monitoring and protection systems. The data collected by these sensors can be processed and analyzed in real-time to assess machinery health, identify potential issues, and trigger alarms or shutdowns when abnormal conditions are detected.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...