Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

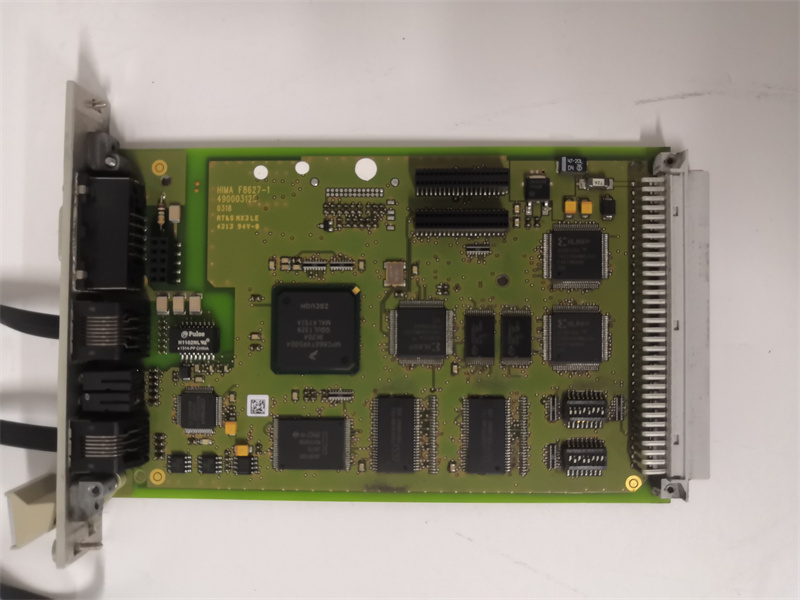

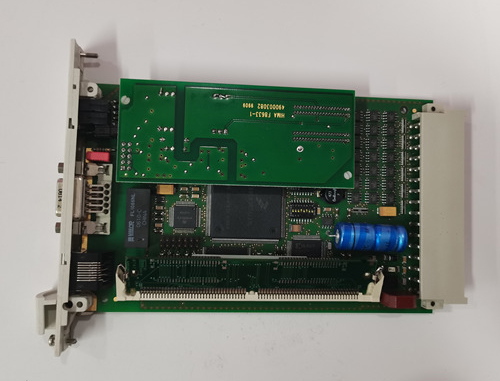

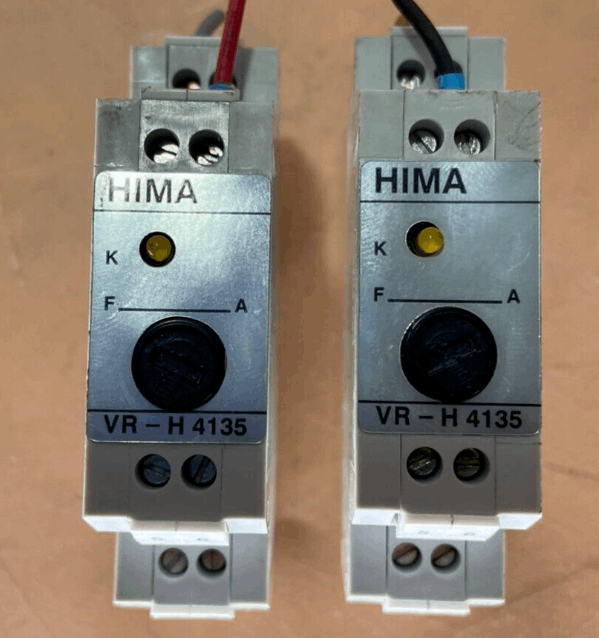

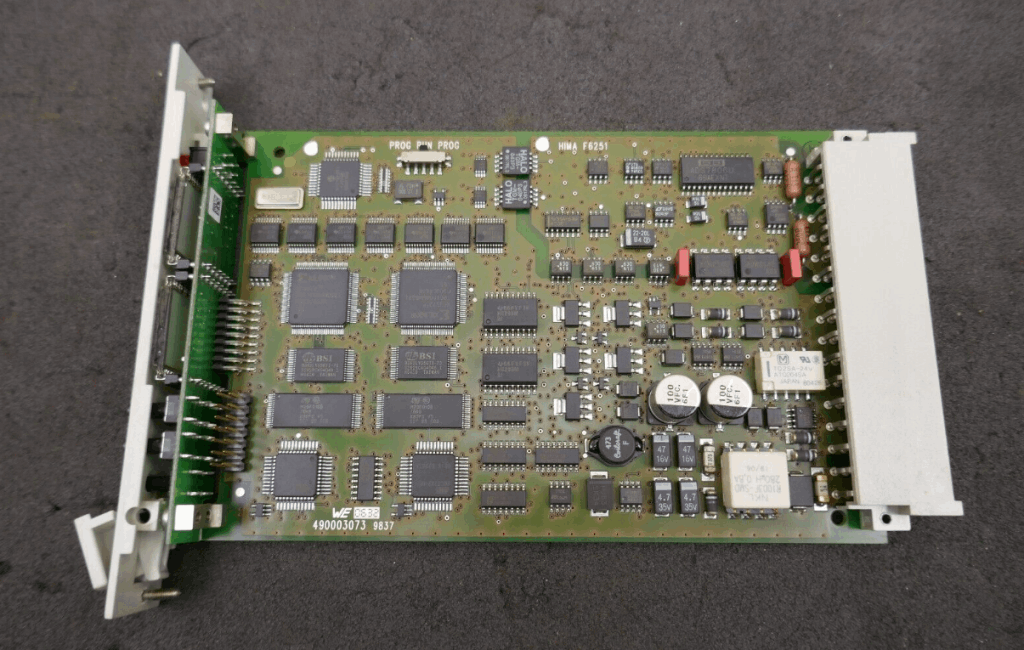

Hima F35011 Safety Controller Module

Manufacturer:HIMA

Product Number:F35011

Product Type:Safety Controller Module

Origin:Germany

Dimensions:130 × 40 × 160 mm

Weight :0.45 kg

Views:165

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

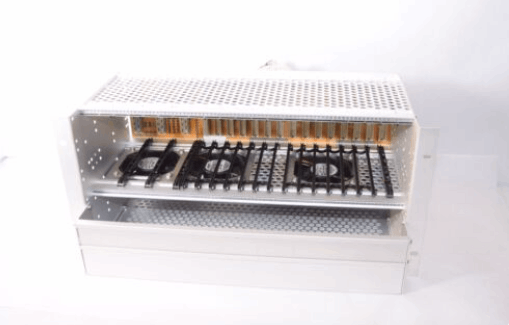

The HIMA F35011 Safety Controller Module is an advanced component designed for high-reliability safety automation systems. It is widely used in industries such as oil and gas, chemical processing, power generation, and transportation, where compliance with strict safety standards (IEC 61508, SIL 3) is essential.

This module serves as a central element in safety-critical applications, enabling precise monitoring, logic execution, and fault detection. Its redundant architecture, diagnostic functions, and secure communication protocols make it an indispensable choice for plants requiring continuous and fail-safe operation.

Product Advantages

High Safety Integrity – Certified for SIL 3 applications, ensuring compliance with stringent safety regulations.

Reliability under Harsh Conditions – Built with industrial-grade components resistant to vibration, temperature fluctuations, and electrical disturbances.

Redundant Architecture – Supports hot-swappable and redundant configurations for uninterrupted operation.

Advanced Diagnostics – Continuous self-monitoring with fault isolation capabilities to minimize downtime.

Flexible Integration – Compatible with a wide range of HIMA safety systems and open communication standards (Profibus, Ethernet, etc.).

Long Lifecycle Support – Designed for long-term availability and backward compatibility with existing HIMA solutions.

Technical Specifications

| Parameter | Value |

|---|---|

| Model | HIMA F35011 Safety Controller Module |

| Function | Safety logic execution and monitoring |

| Safety Certification | IEC 61508 SIL 3 compliant |

| Dimensions | 130 × 40 × 160 mm |

| Weight | 0.45 kg |

| Power Supply | 24 V DC (nominal), with tolerance ±20% |

| Operating Temperature | -20 °C to +60 °C |

| Storage Temperature | -40 °C to +85 °C |

| Communication Interfaces | Profibus, Industrial Ethernet, HIMA system bus |

| Diagnostics | Online self-checks, fault reporting, redundant status monitoring |

| Installation | DIN rail mounting |

| Compatibility | Compatible with HIMax and HIQuad-X safety systems |

Product Applications

Oil & Gas – Emergency shutdown systems (ESD), fire and gas systems (F&G).

Power Generation – Turbine control, boiler protection, nuclear plant safety automation.

Petrochemical Industry – Burner management systems, process safeguarding.

Transportation – Railway safety interlocking and signaling systems.

Chemical Plants – Process shutdown systems and toxic gas leak prevention.

Industrial Manufacturing – Safety interlocks and machine protection systems.

FAQ

Q1: What communication protocols does the HIMA F35011 support?

A1: It supports Profibus, Industrial Ethernet, and HIMA’s proprietary system bus for seamless integration.

Q2: Can the F35011 module be used in redundant configurations?

A2: Yes, it supports redundant and hot-swappable configurations to ensure zero downtime.

Q3: What is the maximum SIL level supported?

A3: The module is certified for SIL 3 applications in compliance with IEC 61508.

Q4: Does the F35011 provide built-in diagnostics?

A4: Yes, it features continuous self-diagnostics and fault isolation reporting.

Q5: Is it compatible with existing HIMA systems like HIMax?

A5: Yes, the F35011 is designed for compatibility with HIMax and HIQuad-X systems.

Q6: How does the module ensure fault tolerance?

A6: It uses redundant architecture and automatic switchover mechanisms to maintain operation during component failures.

Q7: What is the nominal input power requirement?

A7: The F35011 operates with a 24 V DC supply with ±20% tolerance.

Q8: Does the module support online maintenance?

A8: Yes, it allows hot-swapping and diagnostics without system shutdown.

Q9: How does it handle communication failures?

A9: The module uses watchdog timers and fault detection mechanisms to isolate and report communication failures.

Q10: Can the F35011 be integrated into third-party DCS or PLC systems?

A10: Yes, integration is possible via standard industrial communication protocols.

Hima F35011 Safety Controller Module

Manufacturer:HIMA

Product Number:F35011

Product Type:Safety Controller Module

Origin:Germany

Dimensions:130 × 40 × 160 mm

Weight :0.45 kg

Views:165

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The HIMA F35011 Safety Controller Module is an advanced component designed for high-reliability safety automation systems. It is widely used in industries such as oil and gas, chemical processing, power generation, and transportation, where compliance with strict safety standards (IEC 61508, SIL 3) is essential.

This module serves as a central element in safety-critical applications, enabling precise monitoring, logic execution, and fault detection. Its redundant architecture, diagnostic functions, and secure communication protocols make it an indispensable choice for plants requiring continuous and fail-safe operation.

Product Advantages

High Safety Integrity – Certified for SIL 3 applications, ensuring compliance with stringent safety regulations.

Reliability under Harsh Conditions – Built with industrial-grade components resistant to vibration, temperature fluctuations, and electrical disturbances.

Redundant Architecture – Supports hot-swappable and redundant configurations for uninterrupted operation.

Advanced Diagnostics – Continuous self-monitoring with fault isolation capabilities to minimize downtime.

Flexible Integration – Compatible with a wide range of HIMA safety systems and open communication standards (Profibus, Ethernet, etc.).

Long Lifecycle Support – Designed for long-term availability and backward compatibility with existing HIMA solutions.

Technical Specifications

| Parameter | Value |

|---|---|

| Model | HIMA F35011 Safety Controller Module |

| Function | Safety logic execution and monitoring |

| Safety Certification | IEC 61508 SIL 3 compliant |

| Dimensions | 130 × 40 × 160 mm |

| Weight | 0.45 kg |

| Power Supply | 24 V DC (nominal), with tolerance ±20% |

| Operating Temperature | -20 °C to +60 °C |

| Storage Temperature | -40 °C to +85 °C |

| Communication Interfaces | Profibus, Industrial Ethernet, HIMA system bus |

| Diagnostics | Online self-checks, fault reporting, redundant status monitoring |

| Installation | DIN rail mounting |

| Compatibility | Compatible with HIMax and HIQuad-X safety systems |

Product Applications

Oil & Gas – Emergency shutdown systems (ESD), fire and gas systems (F&G).

Power Generation – Turbine control, boiler protection, nuclear plant safety automation.

Petrochemical Industry – Burner management systems, process safeguarding.

Transportation – Railway safety interlocking and signaling systems.

Chemical Plants – Process shutdown systems and toxic gas leak prevention.

Industrial Manufacturing – Safety interlocks and machine protection systems.

FAQ

Q1: What communication protocols does the HIMA F35011 support?

A1: It supports Profibus, Industrial Ethernet, and HIMA’s proprietary system bus for seamless integration.

Q2: Can the F35011 module be used in redundant configurations?

A2: Yes, it supports redundant and hot-swappable configurations to ensure zero downtime.

Q3: What is the maximum SIL level supported?

A3: The module is certified for SIL 3 applications in compliance with IEC 61508.

Q4: Does the F35011 provide built-in diagnostics?

A4: Yes, it features continuous self-diagnostics and fault isolation reporting.

Q5: Is it compatible with existing HIMA systems like HIMax?

A5: Yes, the F35011 is designed for compatibility with HIMax and HIQuad-X systems.

Q6: How does the module ensure fault tolerance?

A6: It uses redundant architecture and automatic switchover mechanisms to maintain operation during component failures.

Q7: What is the nominal input power requirement?

A7: The F35011 operates with a 24 V DC supply with ±20% tolerance.

Q8: Does the module support online maintenance?

A8: Yes, it allows hot-swapping and diagnostics without system shutdown.

Q9: How does it handle communication failures?

A9: The module uses watchdog timers and fault detection mechanisms to isolate and report communication failures.

Q10: Can the F35011 be integrated into third-party DCS or PLC systems?

A10: Yes, integration is possible via standard industrial communication protocols.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...