Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

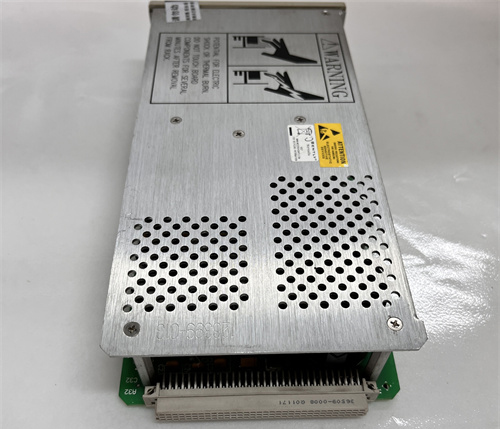

Bently Nevada 3300/16-02-01-02-01-00-00 Dual Vibration Monitor

Brand:Bently Nevada

Model Number:3300/16-02-01-02-01-00-00

Product Origin:USA

Payment:T/T, Western Union, Credit Card

Dimensions:5.7 cm x 20.3 cm x 33.0 cm

Weight:1.5 kg

Price:USD59

Certificate:CE

Warranty:1 years

Product Description

The Bently Nevada 3300/16-02-01-02-01-00-00 is a specialized vibration monitoring device designed for rotating machinery. This XY/Gap Dual Vibration Monitor is ideal for a range of industrial applications.

Key Features and Specifications

- Dual Channel Measurement: Measures two independent channels of radial vibration simultaneously.

- Shaft Position Monitoring: Continuously monitors the average shaft position (gap) using proximity probes.

- High Precision: Provides precise vibration parameter measurements to detect potential faults early.

- Reliability: Built to endure harsh industrial environments and ensure long-term reliable operation.

- Compatibility: Integrates seamlessly with other Bently Nevada systems and industry-standard protocols.

- Customization: Configurable to meet specific application requirements.

Applications

The Bently Nevada 3300/16 excels in various monitoring tasks, including:

- Turbine Monitoring: Measures vibrations in gas, steam, and hydroelectric turbines.

- Compressor Monitoring: Assesses the vibrational health of centrifugal and axial compressors.

- Pump Monitoring: Analyzes vibrations in various types of pumps.

- Motor Monitoring: Monitors vibrations in electric motors.

- Generator Monitoring: Evaluates the vibrational health of generators.

Technical Specifications

- Inputs: Typically accepts signals from two proximity probes.

- Outputs: Offers analog and digital outputs for data acquisition and control systems.

- Communication: Supports various communication protocols for integration into larger systems.

- Environmental Rating: Operates effectively in a wide range of industrial environments.

Benefits

- Early Fault Detection: Prevents costly equipment failures by detecting anomalies early.

- Improved Reliability: Enhances equipment uptime and operational efficiency.

- Reduced Maintenance Costs: Enables condition-based maintenance strategies.

- Enhanced Safety: Ensures safe operation of rotating machinery.

Bently Nevada 3300/16-02-01-02-01-00-00 Dual Vibration Monitor

Brand:Bently Nevada

Model Number:3300/16-02-01-02-01-00-00

Product Origin:USA

Payment:T/T, Western Union, Credit Card

Dimensions:5.7 cm x 20.3 cm x 33.0 cm

Weight:1.5 kg

Price:USD59

Certificate:CE

Warranty:1 years

Product Description

The Bently Nevada 3300/16-02-01-02-01-00-00 is a specialized vibration monitoring device designed for rotating machinery. This XY/Gap Dual Vibration Monitor is ideal for a range of industrial applications.

Key Features and Specifications

- Dual Channel Measurement: Measures two independent channels of radial vibration simultaneously.

- Shaft Position Monitoring: Continuously monitors the average shaft position (gap) using proximity probes.

- High Precision: Provides precise vibration parameter measurements to detect potential faults early.

- Reliability: Built to endure harsh industrial environments and ensure long-term reliable operation.

- Compatibility: Integrates seamlessly with other Bently Nevada systems and industry-standard protocols.

- Customization: Configurable to meet specific application requirements.

Applications

The Bently Nevada 3300/16 excels in various monitoring tasks, including:

- Turbine Monitoring: Measures vibrations in gas, steam, and hydroelectric turbines.

- Compressor Monitoring: Assesses the vibrational health of centrifugal and axial compressors.

- Pump Monitoring: Analyzes vibrations in various types of pumps.

- Motor Monitoring: Monitors vibrations in electric motors.

- Generator Monitoring: Evaluates the vibrational health of generators.

Technical Specifications

- Inputs: Typically accepts signals from two proximity probes.

- Outputs: Offers analog and digital outputs for data acquisition and control systems.

- Communication: Supports various communication protocols for integration into larger systems.

- Environmental Rating: Operates effectively in a wide range of industrial environments.

Benefits

- Early Fault Detection: Prevents costly equipment failures by detecting anomalies early.

- Improved Reliability: Enhances equipment uptime and operational efficiency.

- Reduced Maintenance Costs: Enables condition-based maintenance strategies.

- Enhanced Safety: Ensures safe operation of rotating machinery.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...