Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

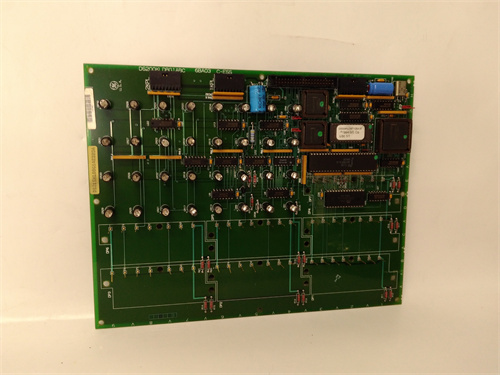

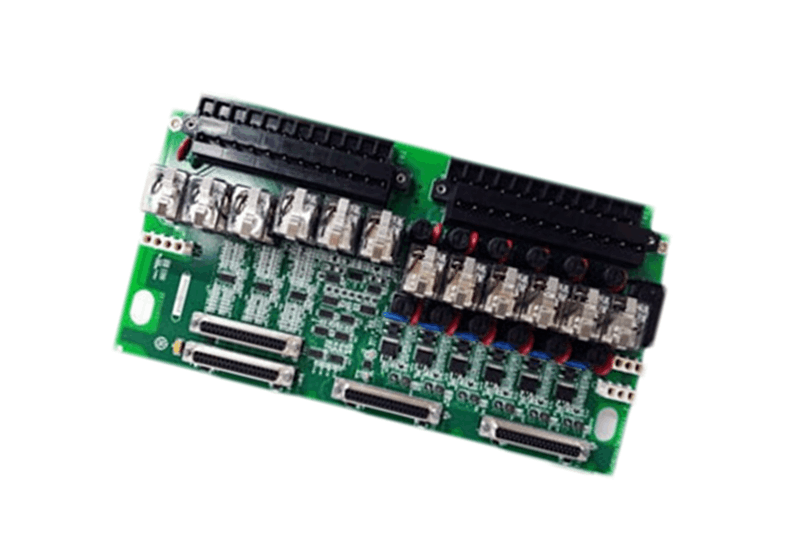

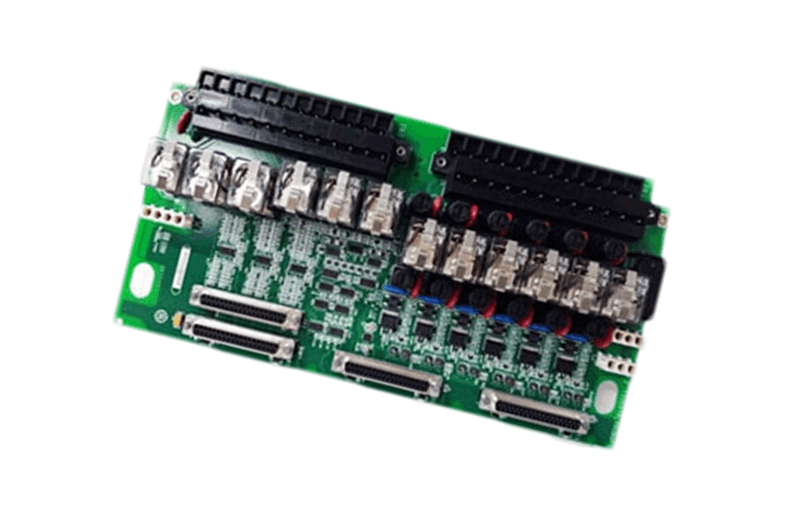

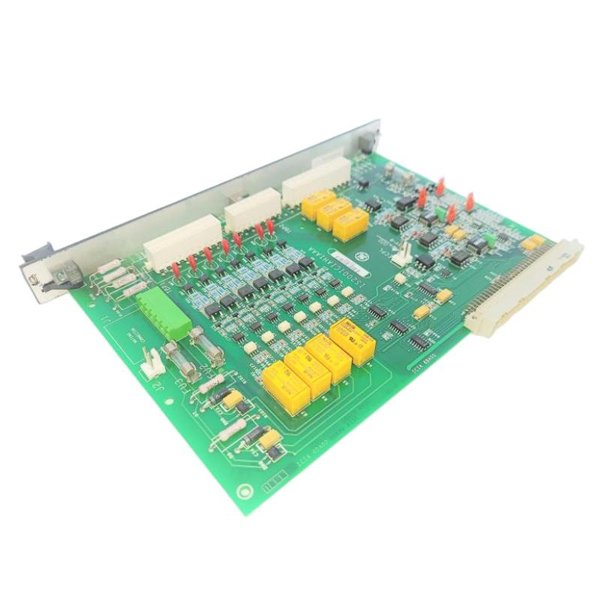

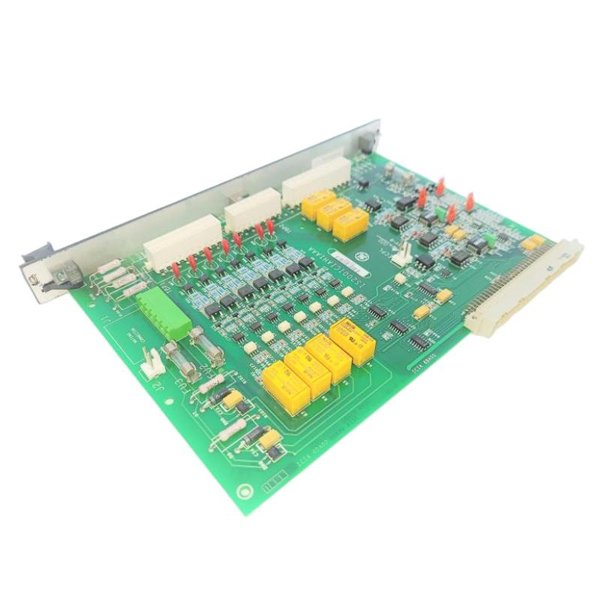

General Electric IS200ICIAH1ABB Innovation I/O Board

Manufacturer:GE

Product Number:IS200ICIAH1ABB

Product Type:Innovation I/O Board

Origin:USA

Dimensions:270 × 190 × 30 mm

Weight:0.454 kg

Views:13

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200ICIAH1ABB Innovation I/O Board is a high-performance input/output interface module engineered for GE Mark VI and Mark VIe control platforms.

It acts as a critical communication bridge between field devices and the main control processor, managing high-speed digital and analog signals with superior accuracy.

Built with a multilayer FR-4 PCB and industrial-grade components, the IS200ICIAH1ABB ensures precise signal conditioning, noise suppression, and galvanic isolation, all essential for stable turbine, generator, and large-scale industrial automation systems.

Its modular design supports rapid installation and replacement, making it a reliable choice for continuous operation in mission-critical environments such as power generation, petrochemical plants, and marine propulsion systems.

Product Specifications

| Parameter | Value |

|---|---|

| Model Number | IS200ICIAH1ABB |

| Product Type | Innovation I/O Board |

| Function | High-speed analog & digital input/output processing |

| Compatible System | GE Mark VI / Mark VIe Control Systems |

| Power Supply | 24 V DC nominal (18–30 V DC tolerance) |

| Analog Input Range | 0–10 V or 4–20 mA (software configurable) |

| Analog Output Range | 0–10 V, ±10 V, or 4–20 mA |

| Digital I/O Channels | 16 optically isolated inputs / 16 relay outputs |

| Signal Isolation | 1500 V RMS between field and logic circuits |

| Conversion Resolution | 16-bit A/D and D/A |

| Update Rate | 1 kHz per channel (typical) |

| Communication Interface | Redundant proprietary backplane bus |

| Operating Temperature | –20 °C to +65 °C |

| Storage Temperature | –40 °C to +85 °C |

| Humidity | 5 %–95 % non-condensing |

| PCB Material | High-temperature FR-4, multilayer |

| Diagnostic Indicators | Dual LED (Power / Channel Status) |

| Mounting Method | Rack-mounted, four-point standoff |

| Dimensions (L × W × H) | 270 × 190 × 30 mm |

| Weight | 0.454 kg |

| Compliance | CE, UL recognized, RoHS compliant |

Applications

The IS200ICIAH1ABB is designed for diverse high-reliability control and monitoring tasks, including:

Steam and Gas Turbine Control – high-speed feedback and command signal handling for Mark VI/VIe controllers.

Power Generation Plants – interfaces analog sensors and digital actuators for generator protection and regulation.

Industrial Automation – integrates with process instrumentation in chemical, pharmaceutical, and steel industries.

Marine Propulsion Systems – provides robust I/O for engine and generator monitoring in marine environments.

Renewable Energy Facilities – coordinates sensor networks and actuator control in wind or hydro installations.

Grid Stabilization Equipment – enables precise I/O management for frequency and voltage regulation systems.

Advantages

High-Speed Processing – 1 kHz per-channel update rate for real-time control loops.

Accurate Signal Conversion – 16-bit resolution ensures precise analog measurement and output.

Robust Isolation – 1500 V RMS galvanic isolation safeguards sensitive logic circuits.

Flexible I/O Configuration – software-selectable analog ranges and mixed digital/analog channels.

Industrial Durability – wide operating temperature and vibration-resistant design.

Easy Maintenance – modular rack mounting and diagnostic LEDs simplify installation and troubleshooting.

Low Noise Design – multilayer PCB with integrated filtering provides superior EMI immunity.

System Compatibility – seamless integration with GE Mark VI/VIe redundant control networks.

FAQ

What control systems support the IS200ICIAH1ABB?

It is fully compatible with GE Mark VI and Mark VIe control platforms.

What is the analog input range?

0–10 V or 4–20 mA, selectable through software configuration.

How many digital input channels are available?

Sixteen optically isolated digital inputs.

Does the board provide analog output capability?

Yes, it offers 0–10 V, ±10 V, or 4–20 mA outputs.

What is the resolution of the A/D and D/A converters?

16-bit resolution for both analog-to-digital and digital-to-analog conversion.

What is the maximum per-channel update rate?

Approximately 1 kHz per channel under typical conditions.

Is galvanic isolation provided between field and logic circuits?

Yes, with 1500 V RMS isolation.

What diagnostic features are present?

Dual LEDs display power and per-channel status for rapid troubleshooting.

What is the recommended power supply specification?

24 V DC nominal with an acceptable range of 18–30 V DC.

How does the board communicate with the main controller?

Through a redundant proprietary GE backplane bus for high reliability.

General Electric IS200ICIAH1ABB Innovation I/O Board

Manufacturer:GE

Product Number:IS200ICIAH1ABB

Product Type:Innovation I/O Board

Origin:USA

Dimensions:270 × 190 × 30 mm

Weight:0.454 kg

Views:13

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200ICIAH1ABB Innovation I/O Board is a high-performance input/output interface module engineered for GE Mark VI and Mark VIe control platforms.

It acts as a critical communication bridge between field devices and the main control processor, managing high-speed digital and analog signals with superior accuracy.

Built with a multilayer FR-4 PCB and industrial-grade components, the IS200ICIAH1ABB ensures precise signal conditioning, noise suppression, and galvanic isolation, all essential for stable turbine, generator, and large-scale industrial automation systems.

Its modular design supports rapid installation and replacement, making it a reliable choice for continuous operation in mission-critical environments such as power generation, petrochemical plants, and marine propulsion systems.

Product Specifications

| Parameter | Value |

|---|---|

| Model Number | IS200ICIAH1ABB |

| Product Type | Innovation I/O Board |

| Function | High-speed analog & digital input/output processing |

| Compatible System | GE Mark VI / Mark VIe Control Systems |

| Power Supply | 24 V DC nominal (18–30 V DC tolerance) |

| Analog Input Range | 0–10 V or 4–20 mA (software configurable) |

| Analog Output Range | 0–10 V, ±10 V, or 4–20 mA |

| Digital I/O Channels | 16 optically isolated inputs / 16 relay outputs |

| Signal Isolation | 1500 V RMS between field and logic circuits |

| Conversion Resolution | 16-bit A/D and D/A |

| Update Rate | 1 kHz per channel (typical) |

| Communication Interface | Redundant proprietary backplane bus |

| Operating Temperature | –20 °C to +65 °C |

| Storage Temperature | –40 °C to +85 °C |

| Humidity | 5 %–95 % non-condensing |

| PCB Material | High-temperature FR-4, multilayer |

| Diagnostic Indicators | Dual LED (Power / Channel Status) |

| Mounting Method | Rack-mounted, four-point standoff |

| Dimensions (L × W × H) | 270 × 190 × 30 mm |

| Weight | 0.454 kg |

| Compliance | CE, UL recognized, RoHS compliant |

Applications

The IS200ICIAH1ABB is designed for diverse high-reliability control and monitoring tasks, including:

Steam and Gas Turbine Control – high-speed feedback and command signal handling for Mark VI/VIe controllers.

Power Generation Plants – interfaces analog sensors and digital actuators for generator protection and regulation.

Industrial Automation – integrates with process instrumentation in chemical, pharmaceutical, and steel industries.

Marine Propulsion Systems – provides robust I/O for engine and generator monitoring in marine environments.

Renewable Energy Facilities – coordinates sensor networks and actuator control in wind or hydro installations.

Grid Stabilization Equipment – enables precise I/O management for frequency and voltage regulation systems.

Advantages

High-Speed Processing – 1 kHz per-channel update rate for real-time control loops.

Accurate Signal Conversion – 16-bit resolution ensures precise analog measurement and output.

Robust Isolation – 1500 V RMS galvanic isolation safeguards sensitive logic circuits.

Flexible I/O Configuration – software-selectable analog ranges and mixed digital/analog channels.

Industrial Durability – wide operating temperature and vibration-resistant design.

Easy Maintenance – modular rack mounting and diagnostic LEDs simplify installation and troubleshooting.

Low Noise Design – multilayer PCB with integrated filtering provides superior EMI immunity.

System Compatibility – seamless integration with GE Mark VI/VIe redundant control networks.

FAQ

What control systems support the IS200ICIAH1ABB?

It is fully compatible with GE Mark VI and Mark VIe control platforms.

What is the analog input range?

0–10 V or 4–20 mA, selectable through software configuration.

How many digital input channels are available?

Sixteen optically isolated digital inputs.

Does the board provide analog output capability?

Yes, it offers 0–10 V, ±10 V, or 4–20 mA outputs.

What is the resolution of the A/D and D/A converters?

16-bit resolution for both analog-to-digital and digital-to-analog conversion.

What is the maximum per-channel update rate?

Approximately 1 kHz per channel under typical conditions.

Is galvanic isolation provided between field and logic circuits?

Yes, with 1500 V RMS isolation.

What diagnostic features are present?

Dual LEDs display power and per-channel status for rapid troubleshooting.

What is the recommended power supply specification?

24 V DC nominal with an acceptable range of 18–30 V DC.

How does the board communicate with the main controller?

Through a redundant proprietary GE backplane bus for high reliability.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...