Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

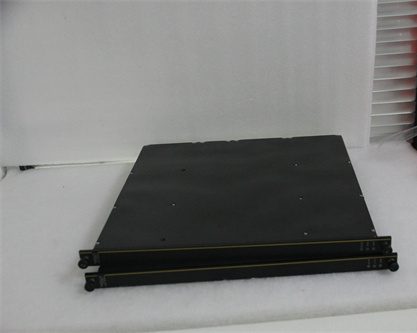

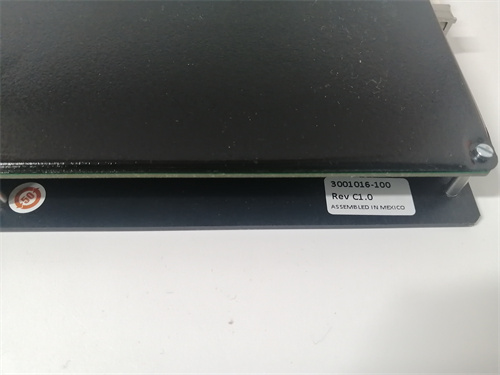

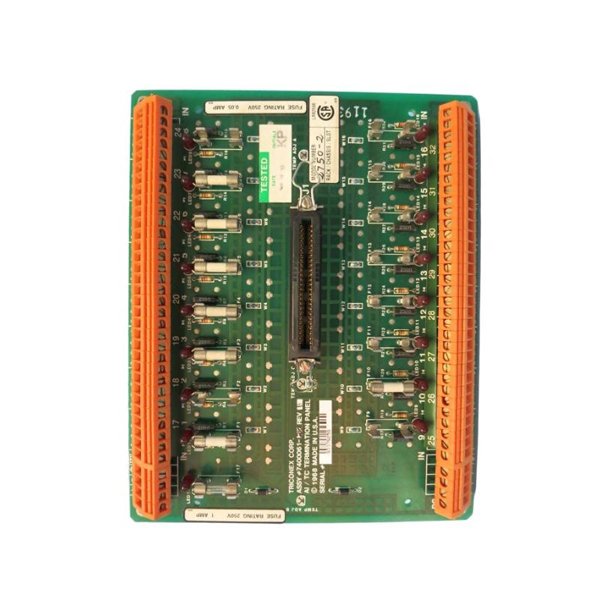

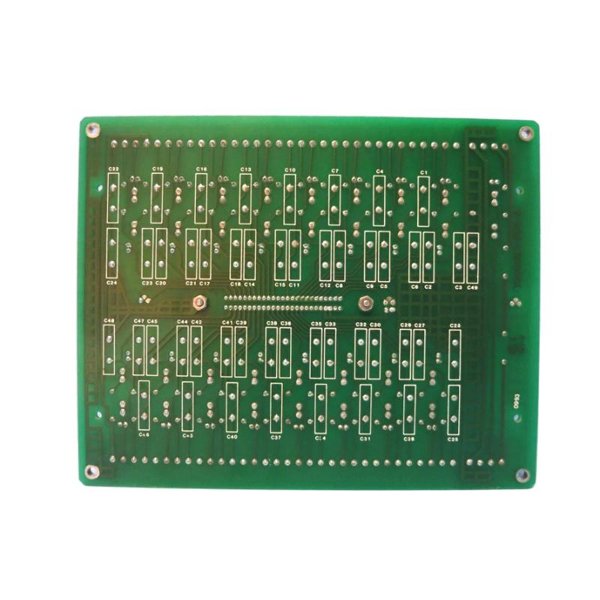

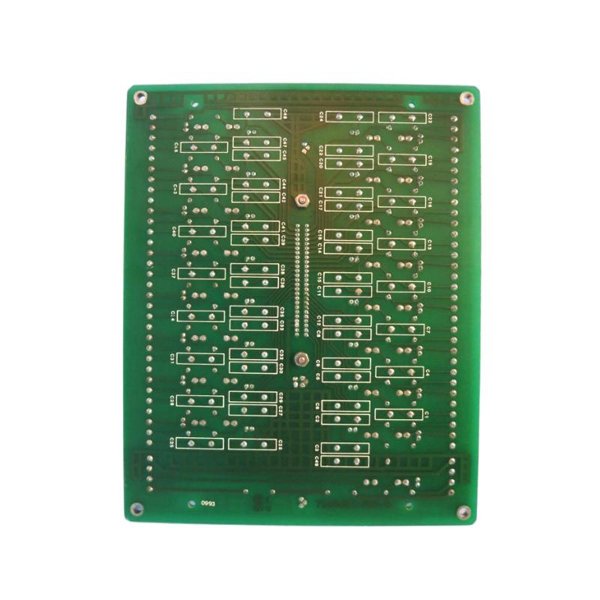

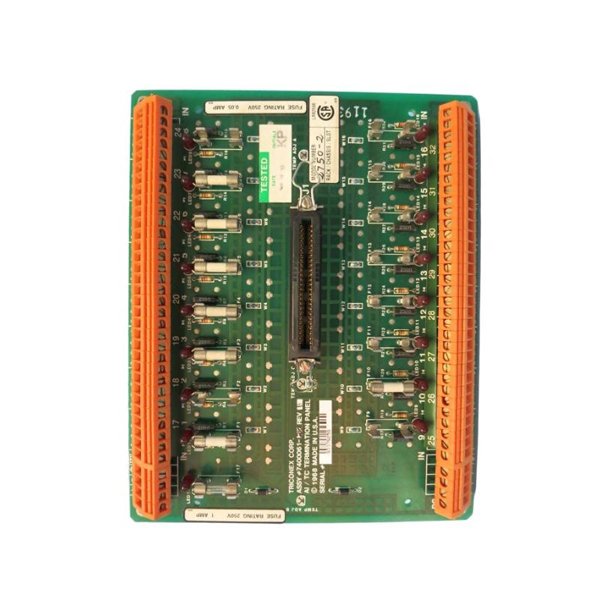

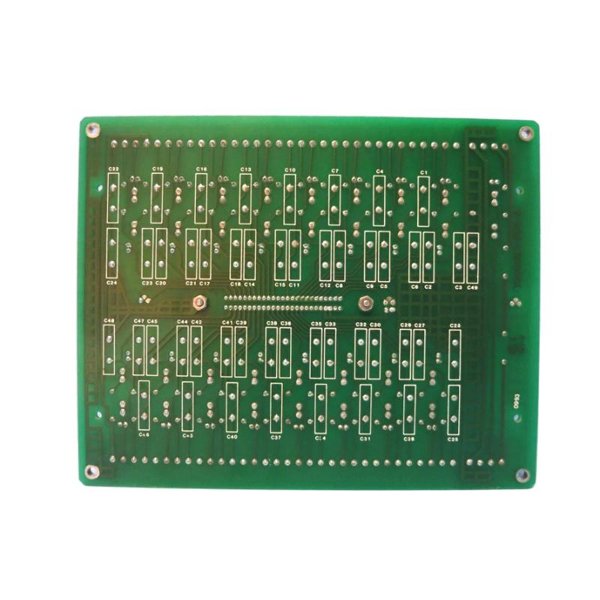

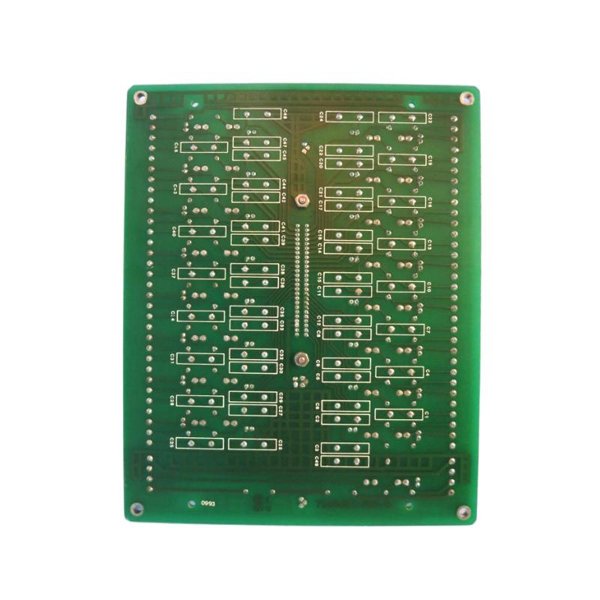

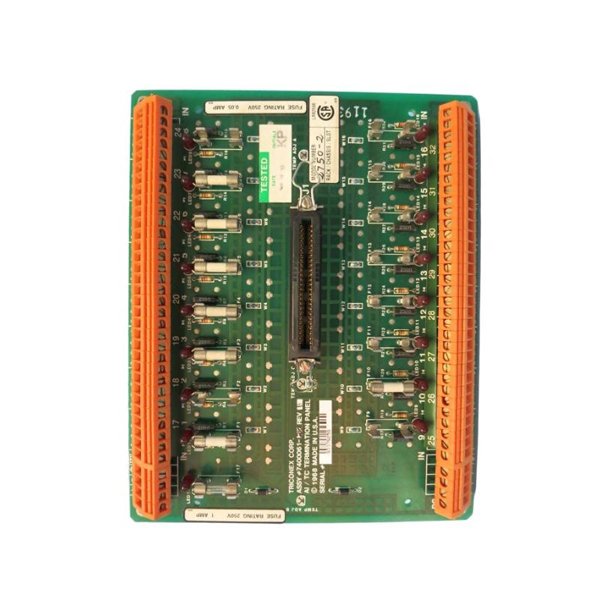

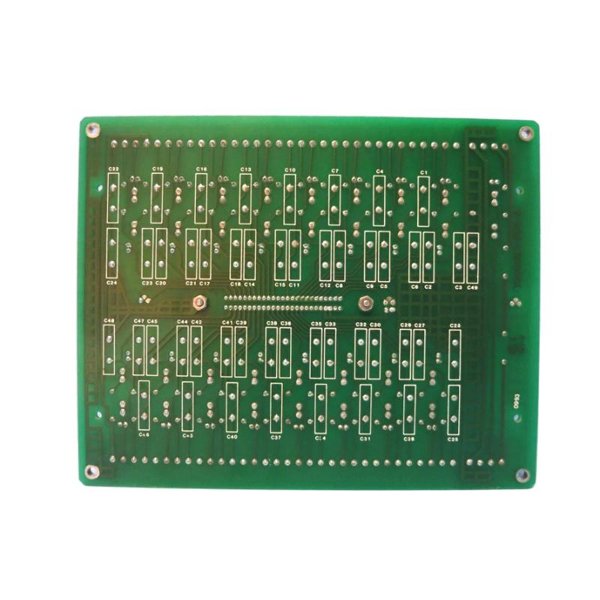

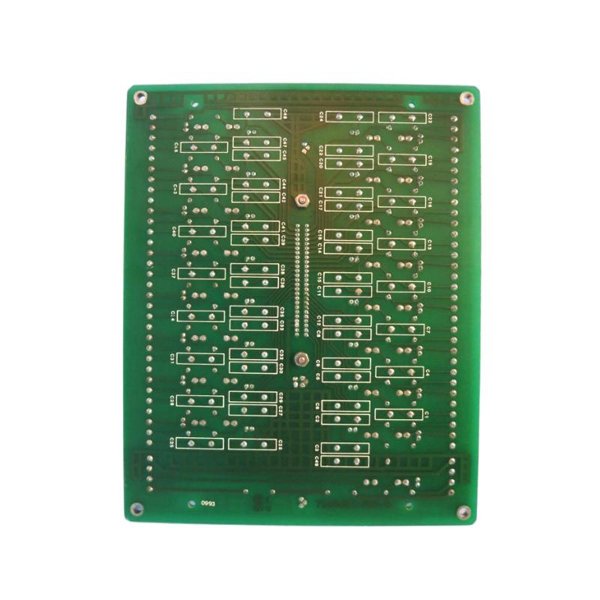

Triconex 300012-220 Terminal Panel

Manufacturer:Triconex

Product Number:300012-220

Product Type:Terminal Panel

Origin:USA

Dimensions:265 × 100 × 150 mm

Weight:1.5 kg

Views:33

Payment Methods:T/T, PayPal, Western Union

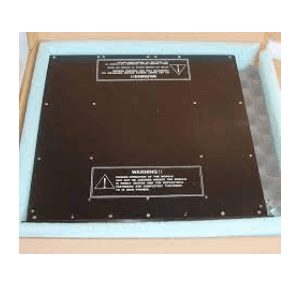

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

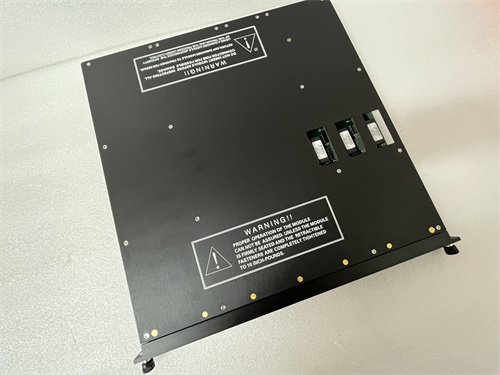

The Triconex 300012-220 Terminal Panel is a precision-engineered interface unit designed to facilitate the connection between field wiring and Triconex safety system modules. Serving as a centralized termination point, the terminal panel ensures organized signal routing, reliable electrical connections, and simplified maintenance for large-scale industrial automation systems.

Specifically developed for integration with Triconex 3000 series modules, the 300012-220 Terminal Panel provides high-quality electrical terminations for digital and analog signals, safeguarding the integrity of critical process control data. Its design supports clear labeling, structured wiring paths, and secure mounting in industrial control cabinets. The terminal panel plays a vital role in environments where uninterrupted operation and precise signal transmission are essential, such as oil and gas facilities, petrochemical plants, power generation stations, and chemical processing plants.

Additionally, the 300012-220 Terminal Panel enhances system reliability by enabling easier diagnostics, quicker fault isolation, and straightforward replacement of modules or wiring segments without disrupting the operational process.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 300012-220 |

| Device Type | Terminal Panel |

| Connection Type | Screw terminals / plug-in connectors |

| Signal Type | Digital and analog signals |

| Module Compatibility | Triconex 3000 series I/O modules |

| Operating Temperature | 0°C to 60°C |

| Storage Temperature | -40°C to 85°C |

| Humidity | 5% to 95% RH, non-condensing |

| Mounting | Panel or DIN rail mountable |

| Diagnostics | LED status indicators for each channel |

| Dimensions (W x H x D) | 265 × 100 × 150 mm |

| Weight | 1.5 kg |

| Certifications | IEC61508, CE |

Applications

The 300012-220 Terminal Panel is widely used in various industrial sectors for safety and control systems:

Oil and Gas Platforms – Termination for ESD systems, gas detectors, and emergency shutdown loops.

Petrochemical Plants – Centralized wiring for safety instrumented systems (SIS) and interlock devices.

Power Generation Facilities – Organization and termination of signals from turbine trips, alarms, and protective relays.

Chemical Processing Plants – Handling valve positions, level sensors, and flow interlocks with high reliability.

Mining and Metals – Ensures organized connectivity for critical equipment monitoring.

Nuclear and High-Safety Facilities – Termination for SIL-certified control and safety systems requiring accurate signal routing.

Advantages

The Triconex 300012-220 Terminal Panel offers multiple operational and technical benefits:

Organized Wiring – Structured layout reduces installation errors and simplifies maintenance.

Reliable Electrical Connections – High-quality screw terminals and connectors ensure stable contact for critical signals.

Enhanced Diagnostics – LED indicators allow quick detection of signal status and fault identification.

Compatibility – Fully integrates with Triconex 3000 series I/O modules and control systems.

Robust Design – Designed for industrial environments, resistant to vibration, dust, and temperature variations.

Simplified Maintenance – Modular design enables replacement or expansion without system downtime.

Support for Safety-Critical Systems – Compatible with SIL-rated applications ensuring compliance with safety standards.

FAQ

What types of signals can the 300012-220 handle?

It handles both digital and analog signals from Triconex 3000 series modules.

How does the terminal panel improve system diagnostics?

Each channel has an LED indicator showing the active status and fault conditions, allowing rapid troubleshooting.

Is the panel compatible with all Triconex 3000 I/O modules?

Yes, it is designed for seamless integration with standard Triconex 3000 series I/O modules.

Can it be mounted on a DIN rail?

Yes, it supports both panel and DIN rail mounting for flexible installation.

How does it handle high-density wiring?

The panel provides organized routing paths and clear labeling for large numbers of input and output signals.

Does the terminal panel support SIL-rated systems?

Yes, it is compatible with SIL-certified safety instrumented systems.

How is electrical interference managed?

High-quality termination and proper routing minimize the risk of signal cross-talk and EMI interference.

Can field devices be replaced without shutting down the system?

Yes, the modular and structured wiring design allows for field device replacement with minimal system impact.

What maintenance procedures are recommended?

Regular visual inspection of terminals, LED status checks, and verification of secure wiring connections.

Does it require additional power for operation?

No, the terminal panel operates passively using the signals from connected modules and field devices.

Triconex 300012-220 Terminal Panel

Manufacturer:Triconex

Product Number:300012-220

Product Type:Terminal Panel

Origin:USA

Dimensions:265 × 100 × 150 mm

Weight:1.5 kg

Views:33

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Triconex 300012-220 Terminal Panel is a precision-engineered interface unit designed to facilitate the connection between field wiring and Triconex safety system modules. Serving as a centralized termination point, the terminal panel ensures organized signal routing, reliable electrical connections, and simplified maintenance for large-scale industrial automation systems.

Specifically developed for integration with Triconex 3000 series modules, the 300012-220 Terminal Panel provides high-quality electrical terminations for digital and analog signals, safeguarding the integrity of critical process control data. Its design supports clear labeling, structured wiring paths, and secure mounting in industrial control cabinets. The terminal panel plays a vital role in environments where uninterrupted operation and precise signal transmission are essential, such as oil and gas facilities, petrochemical plants, power generation stations, and chemical processing plants.

Additionally, the 300012-220 Terminal Panel enhances system reliability by enabling easier diagnostics, quicker fault isolation, and straightforward replacement of modules or wiring segments without disrupting the operational process.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 300012-220 |

| Device Type | Terminal Panel |

| Connection Type | Screw terminals / plug-in connectors |

| Signal Type | Digital and analog signals |

| Module Compatibility | Triconex 3000 series I/O modules |

| Operating Temperature | 0°C to 60°C |

| Storage Temperature | -40°C to 85°C |

| Humidity | 5% to 95% RH, non-condensing |

| Mounting | Panel or DIN rail mountable |

| Diagnostics | LED status indicators for each channel |

| Dimensions (W x H x D) | 265 × 100 × 150 mm |

| Weight | 1.5 kg |

| Certifications | IEC61508, CE |

Applications

The 300012-220 Terminal Panel is widely used in various industrial sectors for safety and control systems:

Oil and Gas Platforms – Termination for ESD systems, gas detectors, and emergency shutdown loops.

Petrochemical Plants – Centralized wiring for safety instrumented systems (SIS) and interlock devices.

Power Generation Facilities – Organization and termination of signals from turbine trips, alarms, and protective relays.

Chemical Processing Plants – Handling valve positions, level sensors, and flow interlocks with high reliability.

Mining and Metals – Ensures organized connectivity for critical equipment monitoring.

Nuclear and High-Safety Facilities – Termination for SIL-certified control and safety systems requiring accurate signal routing.

Advantages

The Triconex 300012-220 Terminal Panel offers multiple operational and technical benefits:

Organized Wiring – Structured layout reduces installation errors and simplifies maintenance.

Reliable Electrical Connections – High-quality screw terminals and connectors ensure stable contact for critical signals.

Enhanced Diagnostics – LED indicators allow quick detection of signal status and fault identification.

Compatibility – Fully integrates with Triconex 3000 series I/O modules and control systems.

Robust Design – Designed for industrial environments, resistant to vibration, dust, and temperature variations.

Simplified Maintenance – Modular design enables replacement or expansion without system downtime.

Support for Safety-Critical Systems – Compatible with SIL-rated applications ensuring compliance with safety standards.

FAQ

What types of signals can the 300012-220 handle?

It handles both digital and analog signals from Triconex 3000 series modules.

How does the terminal panel improve system diagnostics?

Each channel has an LED indicator showing the active status and fault conditions, allowing rapid troubleshooting.

Is the panel compatible with all Triconex 3000 I/O modules?

Yes, it is designed for seamless integration with standard Triconex 3000 series I/O modules.

Can it be mounted on a DIN rail?

Yes, it supports both panel and DIN rail mounting for flexible installation.

How does it handle high-density wiring?

The panel provides organized routing paths and clear labeling for large numbers of input and output signals.

Does the terminal panel support SIL-rated systems?

Yes, it is compatible with SIL-certified safety instrumented systems.

How is electrical interference managed?

High-quality termination and proper routing minimize the risk of signal cross-talk and EMI interference.

Can field devices be replaced without shutting down the system?

Yes, the modular and structured wiring design allows for field device replacement with minimal system impact.

What maintenance procedures are recommended?

Regular visual inspection of terminals, LED status checks, and verification of secure wiring connections.

Does it require additional power for operation?

No, the terminal panel operates passively using the signals from connected modules and field devices.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...