Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

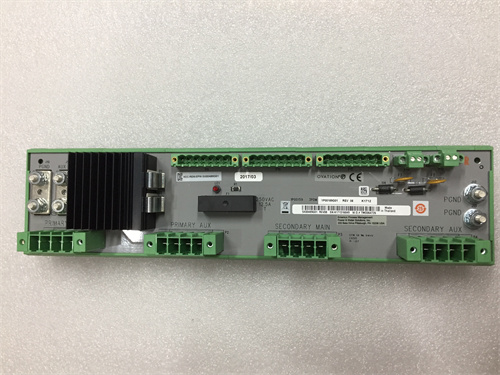

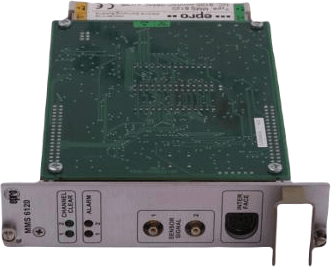

Emerson A6140 Dual-channel Shaft Absolute Vibration Monitor

Brand: Emerson

Model Number: EPRO A6140

Type: Dual-channel Shaft Absolute Vibration Monitor

Condition:Brand NEW & in Stock

Product Origin: Germany

Payment: T/T, Western Union, Credit Card

Width: 30.0 mm (1.181 in) (6 TE)

Height: 128.4 mm (5.055 in) (3 HE)

Length: 160.0 mm (6.300 in)

Net Weight: Approximately 320 g (0.705 lbs)

Gross Weight: Approximately 450 g (0.992 lbs) including standard packing

Packing Volume: Approximately 2.5 dm3 (0.08 ft3)

Warranty: 1 year

Product Description

The Emerson EPRO A6140 Dual-channel Shaft Absolute Vibration Monitor is designed for use with the AMS 6500 Machinery Health Monitor, providing high reliability and critical machinery protection in various industrial applications. Here’s a summary of its key specifications and features:

General Information

- Application: Used to build a complete API 670 machinery protection monitor in conjunction with other AMS 6500 monitors. Suitable for steam, gas, compressors, and hydro turbine machinery.

- Module Type: 1-slot plug-in module, reducing cabinet space requirements compared to traditional four-channel 6U size cards.

- API 670 Compliant: Meets API 670 standards for machinery protection.

- Hot Swappable: Module can be replaced without shutting down the system.

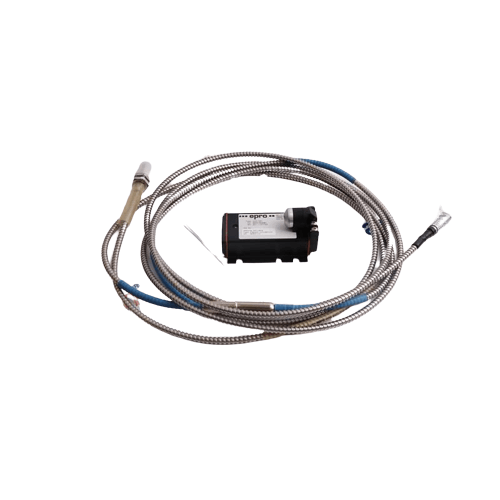

Transducer Inputs

- Number of Inputs: Two independent or combined monitoring modes.

- Type of Inputs: Eddy current, seismic, or piezoelectric, in differential mode.

- Emerson Sensor Inputs: Channel 1 part numbers: 6422, 6423, 6424, 6425; Channel 2 part number: 6125.

- Isolation: Galvanically separated from power supply.

Channel 1 Displacement Sensor

- Input Resistance: >100 kΩ

- Input Voltage Range: -1 to -23 VDC

- Input Frequency Range: Adjustable with lower cutoff at 1 or 5 Hz and upper cutoff between 50 – 2000 Hz.

- Smallest Range: 0 – 400 mV peak to peak

- Largest Range: 0 – 2000 mV peak to peak

- Sensor Power Supply: -26.7 VDC, nominal 20 mA (maximum 35 mA)

Channel 2 Case Vibration Sensor

- Input Resistance: >100 kΩ

- Input Voltage Range: -5 to +15 VDC

- Signal Input Voltage Range: 311 – 9500 mV peak to peak

- Input Frequency Range: Adjustable with lower cutoff at 5 or 10 Hz and upper cutoff between 50 – 1000 or 1600 Hz.

- Sensor Supply for Accelerometer: Constant current, 0 – 8 mA, 30 VDC

Front Panel Outputs

- Green LED’s: Indicate channel OK separately for each channel.

- Red LED’s: Indicate alert and danger separately for each channel.

- Front Panel Buffered Outputs: Two outputs for each channel.

Analysis

- Measurement Modes: Hot configurable, zero to peak, peak to peak, independent dual-channel, or combined dual-channel modes.

- Configurable Parameters: Measuring range, RMS, zero to peak, or peak to peak sensitivity, alert, and danger thresholds, filter frequency ranges.

- Analysis Parameters: Includes ½x, 1 – 10x, and phase angle, available via ModBus TCP/IP output.

Rear Outputs Available

- Current Mode Outputs: 0/4-20 mA output for each channel, proportional to the main value.

- Voltage Mode Outputs: 0 – 10 VDC output proportional to the main value for each channel.

- Rear Buffered Outputs: Raw buffered signal, AC, and DC.

Alarm Setpoints and Alarm Time Delays

- Alert and Danger: Configurable for each channel, with selectable normally open/closed contacts, delay settings, and hysteresis options.

- OK: Self-checking with green LED indicators.

Environmental and General

- Front Plate: IP00, DIN 40050

- Climate: IP21, DIN 40050

- Operating Temperature: DIN 40040 class KTF

- Storage Temperature: 0°C – 65°C (32°F – 149°F)

- Relative Humidity: -30°C – 85°C (-22°F – 185°F)

- Vibration: Compliant with IEC 68-2, part 6

- Shock: Compliant with IEC 68-2, part 29

- EMC Resistance: EN50081-1 / EN50082-2

- Power Consumption: Max. 6 W, 250 mA at 24 VDC

- Configuration: Password protected

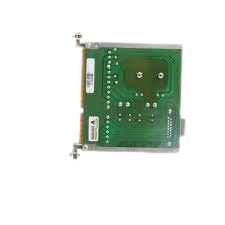

Dimensions and Weight

- Dimensions (PCB/EURO card format): 100 x 160 mm (3.937 x 6.300 in)

- Width: 30.0 mm (1.181 in) (6 TE)

- Height: 128.4 mm (5.055 in) (3 HE)

- Length: 160.0 mm (6.300 in)

- Net Weight: Approximately 320 g (0.705 lbs)

- Gross Weight: Approximately 450 g (0.992 lbs) including standard packing

- Packing Volume: Approximately 2.5 dm3 (0.08 ft3)

Space Requirements

- Occupies 1 slot in a 19″ rack. Up to 14 modules can fit into each 19″ rack.

Ordering Information

- Model Number: A6140

- Product Description: Dual-channel Shaft Absolute Vibration Monitor

The A6140 Dual-channel Shaft Absolute Vibration Monitor is a versatile monitoring solution that meets API 670 standards and provides accurate and reliable machinery protection for critical rotating machinery in industrial plants. It offers various output options and alarm settings to suit different applications and is designed for easy installation and maintenance.

Emerson A6140 Dual-channel Shaft Absolute Vibration Monitor

Brand: Emerson

Model Number: EPRO A6140

Type: Dual-channel Shaft Absolute Vibration Monitor

Condition:Brand NEW & in Stock

Product Origin: Germany

Payment: T/T, Western Union, Credit Card

Width: 30.0 mm (1.181 in) (6 TE)

Height: 128.4 mm (5.055 in) (3 HE)

Length: 160.0 mm (6.300 in)

Net Weight: Approximately 320 g (0.705 lbs)

Gross Weight: Approximately 450 g (0.992 lbs) including standard packing

Packing Volume: Approximately 2.5 dm3 (0.08 ft3)

Warranty: 1 year

Product Description

The Emerson EPRO A6140 Dual-channel Shaft Absolute Vibration Monitor is designed for use with the AMS 6500 Machinery Health Monitor, providing high reliability and critical machinery protection in various industrial applications. Here’s a summary of its key specifications and features:

General Information

- Application: Used to build a complete API 670 machinery protection monitor in conjunction with other AMS 6500 monitors. Suitable for steam, gas, compressors, and hydro turbine machinery.

- Module Type: 1-slot plug-in module, reducing cabinet space requirements compared to traditional four-channel 6U size cards.

- API 670 Compliant: Meets API 670 standards for machinery protection.

- Hot Swappable: Module can be replaced without shutting down the system.

Transducer Inputs

- Number of Inputs: Two independent or combined monitoring modes.

- Type of Inputs: Eddy current, seismic, or piezoelectric, in differential mode.

- Emerson Sensor Inputs: Channel 1 part numbers: 6422, 6423, 6424, 6425; Channel 2 part number: 6125.

- Isolation: Galvanically separated from power supply.

Channel 1 Displacement Sensor

- Input Resistance: >100 kΩ

- Input Voltage Range: -1 to -23 VDC

- Input Frequency Range: Adjustable with lower cutoff at 1 or 5 Hz and upper cutoff between 50 – 2000 Hz.

- Smallest Range: 0 – 400 mV peak to peak

- Largest Range: 0 – 2000 mV peak to peak

- Sensor Power Supply: -26.7 VDC, nominal 20 mA (maximum 35 mA)

Channel 2 Case Vibration Sensor

- Input Resistance: >100 kΩ

- Input Voltage Range: -5 to +15 VDC

- Signal Input Voltage Range: 311 – 9500 mV peak to peak

- Input Frequency Range: Adjustable with lower cutoff at 5 or 10 Hz and upper cutoff between 50 – 1000 or 1600 Hz.

- Sensor Supply for Accelerometer: Constant current, 0 – 8 mA, 30 VDC

Front Panel Outputs

- Green LED’s: Indicate channel OK separately for each channel.

- Red LED’s: Indicate alert and danger separately for each channel.

- Front Panel Buffered Outputs: Two outputs for each channel.

Analysis

- Measurement Modes: Hot configurable, zero to peak, peak to peak, independent dual-channel, or combined dual-channel modes.

- Configurable Parameters: Measuring range, RMS, zero to peak, or peak to peak sensitivity, alert, and danger thresholds, filter frequency ranges.

- Analysis Parameters: Includes ½x, 1 – 10x, and phase angle, available via ModBus TCP/IP output.

Rear Outputs Available

- Current Mode Outputs: 0/4-20 mA output for each channel, proportional to the main value.

- Voltage Mode Outputs: 0 – 10 VDC output proportional to the main value for each channel.

- Rear Buffered Outputs: Raw buffered signal, AC, and DC.

Alarm Setpoints and Alarm Time Delays

- Alert and Danger: Configurable for each channel, with selectable normally open/closed contacts, delay settings, and hysteresis options.

- OK: Self-checking with green LED indicators.

Environmental and General

- Front Plate: IP00, DIN 40050

- Climate: IP21, DIN 40050

- Operating Temperature: DIN 40040 class KTF

- Storage Temperature: 0°C – 65°C (32°F – 149°F)

- Relative Humidity: -30°C – 85°C (-22°F – 185°F)

- Vibration: Compliant with IEC 68-2, part 6

- Shock: Compliant with IEC 68-2, part 29

- EMC Resistance: EN50081-1 / EN50082-2

- Power Consumption: Max. 6 W, 250 mA at 24 VDC

- Configuration: Password protected

Dimensions and Weight

- Dimensions (PCB/EURO card format): 100 x 160 mm (3.937 x 6.300 in)

- Width: 30.0 mm (1.181 in) (6 TE)

- Height: 128.4 mm (5.055 in) (3 HE)

- Length: 160.0 mm (6.300 in)

- Net Weight: Approximately 320 g (0.705 lbs)

- Gross Weight: Approximately 450 g (0.992 lbs) including standard packing

- Packing Volume: Approximately 2.5 dm3 (0.08 ft3)

Space Requirements

- Occupies 1 slot in a 19″ rack. Up to 14 modules can fit into each 19″ rack.

Ordering Information

- Model Number: A6140

- Product Description: Dual-channel Shaft Absolute Vibration Monitor

The A6140 Dual-channel Shaft Absolute Vibration Monitor is a versatile monitoring solution that meets API 670 standards and provides accurate and reliable machinery protection for critical rotating machinery in industrial plants. It offers various output options and alarm settings to suit different applications and is designed for easy installation and maintenance.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...