Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

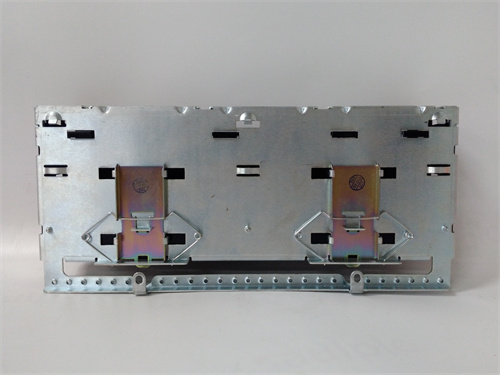

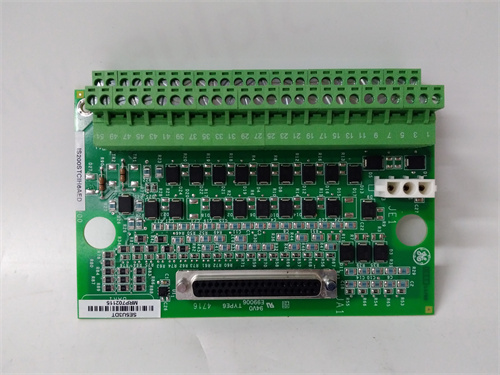

GE Fanuc HE693RTM705 Modbus/RTU Master Interface Module

Manufacturer:General Electric

Part Number:HE693RTM705

Product Type:Modbus/RTU Master Interface Module

Series:GE Speedtronic Mark V

Stock:IN STOCK

Repair:3-7 Day

Rush Repair:24-48 Hrs.

Warranty:3 Years

Dimensions:2.1 cm x 20.2 cm x 26.1 cm

Weight:0.42 kg

Product Description

The GE Fanuc HE693RTM705 is a Modbus/RTU master interface module. It connects and communicates with remote Modbus slave devices. This module features two independent Modbus/RTU master channels. You can configure these channels for various communication modes.

Key Features

- Dual Modbus/RTU Master Channels: Provides two channels for flexible communication.

- Versatile Communication Modes: Supports dial-in, dial-out, radio modem, multi-drop, and direct connection.

- Flexible Data Exchange: Handles both analog and discrete data.

- Multiple Commands: Sends multiple commands to each slave device in a single transaction.

- High Data Transfer Rate: Efficiently transfers data between the PLC and remote devices.

- Easy Configuration: Easily programmed and configured using the PLC’s programming software.

Technical Specifications

- Power Consumption: 425mA @ 5VDC

- Compatibility: Requires a Series 90-70 CPU

- Mounting: Designed to plug into any Series 90-30 local slot

- Data Transfer: Supports up to 250 bytes of data per command

- Communication Protocols: Modbus/RTU

- Physical Interface: RS232, RS422, RS485

Applications

- Industrial Automation: Integrates various devices into a larger control network.

- Process Control: Facilitates data exchange in process control systems.

- SCADA Systems: Connects PLCs with remote devices for monitoring and control.

- Data Acquisition: Collects data from multiple remote slave devices.

GE Fanuc HE693RTM705 Modbus/RTU Master Interface Module

Manufacturer:General Electric

Part Number:HE693RTM705

Product Type:Modbus/RTU Master Interface Module

Series:GE Speedtronic Mark V

Stock:IN STOCK

Repair:3-7 Day

Rush Repair:24-48 Hrs.

Warranty:3 Years

Dimensions:2.1 cm x 20.2 cm x 26.1 cm

Weight:0.42 kg

Product Description

The GE Fanuc HE693RTM705 is a Modbus/RTU master interface module. It connects and communicates with remote Modbus slave devices. This module features two independent Modbus/RTU master channels. You can configure these channels for various communication modes.

Key Features

- Dual Modbus/RTU Master Channels: Provides two channels for flexible communication.

- Versatile Communication Modes: Supports dial-in, dial-out, radio modem, multi-drop, and direct connection.

- Flexible Data Exchange: Handles both analog and discrete data.

- Multiple Commands: Sends multiple commands to each slave device in a single transaction.

- High Data Transfer Rate: Efficiently transfers data between the PLC and remote devices.

- Easy Configuration: Easily programmed and configured using the PLC’s programming software.

Technical Specifications

- Power Consumption: 425mA @ 5VDC

- Compatibility: Requires a Series 90-70 CPU

- Mounting: Designed to plug into any Series 90-30 local slot

- Data Transfer: Supports up to 250 bytes of data per command

- Communication Protocols: Modbus/RTU

- Physical Interface: RS232, RS422, RS485

Applications

- Industrial Automation: Integrates various devices into a larger control network.

- Process Control: Facilitates data exchange in process control systems.

- SCADA Systems: Connects PLCs with remote devices for monitoring and control.

- Data Acquisition: Collects data from multiple remote slave devices.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...