Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

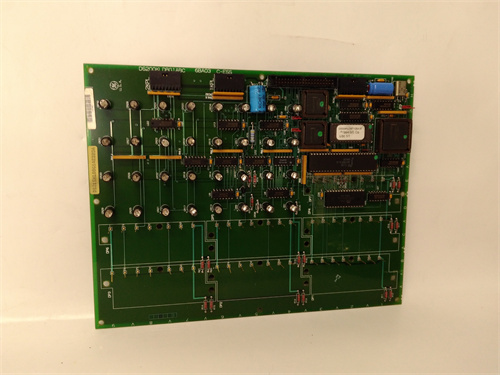

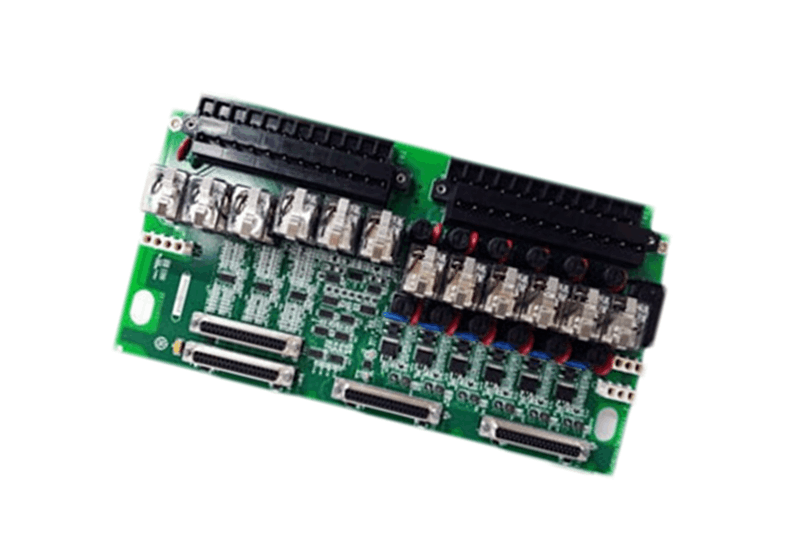

General Electric IS200VROCH1BBR Control Board

Manufacturer:GE

Product Number:IS200VROCH1BBR

Product Type:Control Board

Origin:USA

Dimensions:230 × 110 × 40 mm

Weight:1.15 kg

Views:14

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200VROCH1BBR Control Board is a high-performance module designed for the GE Mark VIe distributed control system. It functions as a vital interface between turbine control logic and field devices, managing real-time operations, executing control algorithms, and ensuring reliable communication with other system components. Engineered with robust isolation, noise immunity, and extended temperature tolerance, the IS200VROCH1BBR is well-suited for demanding industrial environments such as gas, steam, and combined-cycle power plants. Its architecture supports deterministic control cycles, redundant system topologies, and continuous monitoring for critical process applications.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | IS200VROCH1BBR |

| Series | GE Mark VIe Control System |

| Primary Function | High-speed control and real-time I/O processing |

| Power Supply | 24 V DC nominal (18–30 V DC operating range) |

| Processor | High-speed 32-bit embedded microcontroller |

| I/O Channels | Multiple isolated digital and analog interfaces |

| Communication Protocols | Ethernet, RS-485, proprietary Mark VIe backplane bus |

| Isolation Voltage | 2500 V AC minimum between logic and field circuits |

| Operating Temperature | –40 °C to +70 °C |

| Humidity | 0–95 % non-condensing |

| Vibration Resistance | 5 g, 10–2000 Hz |

| Shock Resistance | 30 g, 11 ms half-sine |

| Firmware Support | Mark VIe standard and redundant configurations |

| Dimensions (W×H×D) | 230 × 110 × 40 mm |

| Weight | 1.15 kg |

| Mounting | Rack-mounted or panel-mounted with secure locking connectors |

| Board Material | FR4 PCB with conformal protective coating |

Applications

The IS200VROCH1BBR is widely deployed in:

-

Gas and steam turbine control systems requiring high-speed response

-

Power plant distributed control systems (DCS) and balance-of-plant operations

-

Real-time process automation in petrochemical and industrial facilities

-

Redundant control networks where deterministic data exchange is critical

-

Integration with GE Mark VIe controllers for generator protection and load-shedding logic

Advantages

Deterministic Performance: Guarantees consistent real-time control cycles under heavy loads.

Robust Isolation: High isolation voltage prevents cross-channel interference and protects sensitive electronics.

Flexible Communication: Supports Ethernet and RS-485 as well as native Mark VIe backplane communication.

Industrial Durability: Rated for extreme temperatures, vibration, and electrical noise common in turbine halls.

Redundant Operation: Fully compatible with dual and triple-modular-redundancy Mark VIe topologies.

Ease of Maintenance: Modular design with clearly labeled connectors and built-in diagnostics simplifies service.

Frequently Asked Questions (FAQ)

Which control algorithms can be implemented on the IS200VROCH1BBR?

It supports GE Mark VIe standard control blocks and user-defined algorithms within the system’s software environment.

How does the board ensure deterministic communication over Ethernet?

It employs time-synchronized protocols and priority scheduling to maintain real-time data exchange.

Is hot-swapping supported for maintenance?

Yes, when used in a redundant Mark VIe rack, the board can be hot-swapped with minimal disruption.

What protections exist against electrical noise and surges?

The board includes galvanic isolation, surge suppressors, and EMI/RFI filtering on all I/O channels.

Can it interface directly with third-party PLCs?

Yes, via standard Modbus/TCP or RS-485 serial connections configured through Mark VIe tools.

How is firmware updated in the field?

Firmware can be updated through the Mark VIe system maintenance utility via the backplane or Ethernet port.

What is the typical control loop scan time achievable?

Less than 5 ms under full I/O load, depending on system configuration.

Does the board support redundant power feeds?

Yes, it accepts dual 24 V DC feeds for uninterrupted operation.

How are diagnostic alerts communicated to operators?

Through integrated LED indicators and system alarms transmitted to the Mark VIe HMI.

Can it be integrated into existing Mark VI systems?

Yes, with proper firmware and configuration, it can operate alongside legacy Mark VI equipment.

General Electric IS200VROCH1BBR Control Board

Manufacturer:GE

Product Number:IS200VROCH1BBR

Product Type:Control Board

Origin:USA

Dimensions:230 × 110 × 40 mm

Weight:1.15 kg

Views:14

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200VROCH1BBR Control Board is a high-performance module designed for the GE Mark VIe distributed control system. It functions as a vital interface between turbine control logic and field devices, managing real-time operations, executing control algorithms, and ensuring reliable communication with other system components. Engineered with robust isolation, noise immunity, and extended temperature tolerance, the IS200VROCH1BBR is well-suited for demanding industrial environments such as gas, steam, and combined-cycle power plants. Its architecture supports deterministic control cycles, redundant system topologies, and continuous monitoring for critical process applications.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | IS200VROCH1BBR |

| Series | GE Mark VIe Control System |

| Primary Function | High-speed control and real-time I/O processing |

| Power Supply | 24 V DC nominal (18–30 V DC operating range) |

| Processor | High-speed 32-bit embedded microcontroller |

| I/O Channels | Multiple isolated digital and analog interfaces |

| Communication Protocols | Ethernet, RS-485, proprietary Mark VIe backplane bus |

| Isolation Voltage | 2500 V AC minimum between logic and field circuits |

| Operating Temperature | –40 °C to +70 °C |

| Humidity | 0–95 % non-condensing |

| Vibration Resistance | 5 g, 10–2000 Hz |

| Shock Resistance | 30 g, 11 ms half-sine |

| Firmware Support | Mark VIe standard and redundant configurations |

| Dimensions (W×H×D) | 230 × 110 × 40 mm |

| Weight | 1.15 kg |

| Mounting | Rack-mounted or panel-mounted with secure locking connectors |

| Board Material | FR4 PCB with conformal protective coating |

Applications

The IS200VROCH1BBR is widely deployed in:

-

Gas and steam turbine control systems requiring high-speed response

-

Power plant distributed control systems (DCS) and balance-of-plant operations

-

Real-time process automation in petrochemical and industrial facilities

-

Redundant control networks where deterministic data exchange is critical

-

Integration with GE Mark VIe controllers for generator protection and load-shedding logic

Advantages

Deterministic Performance: Guarantees consistent real-time control cycles under heavy loads.

Robust Isolation: High isolation voltage prevents cross-channel interference and protects sensitive electronics.

Flexible Communication: Supports Ethernet and RS-485 as well as native Mark VIe backplane communication.

Industrial Durability: Rated for extreme temperatures, vibration, and electrical noise common in turbine halls.

Redundant Operation: Fully compatible with dual and triple-modular-redundancy Mark VIe topologies.

Ease of Maintenance: Modular design with clearly labeled connectors and built-in diagnostics simplifies service.

Frequently Asked Questions (FAQ)

Which control algorithms can be implemented on the IS200VROCH1BBR?

It supports GE Mark VIe standard control blocks and user-defined algorithms within the system’s software environment.

How does the board ensure deterministic communication over Ethernet?

It employs time-synchronized protocols and priority scheduling to maintain real-time data exchange.

Is hot-swapping supported for maintenance?

Yes, when used in a redundant Mark VIe rack, the board can be hot-swapped with minimal disruption.

What protections exist against electrical noise and surges?

The board includes galvanic isolation, surge suppressors, and EMI/RFI filtering on all I/O channels.

Can it interface directly with third-party PLCs?

Yes, via standard Modbus/TCP or RS-485 serial connections configured through Mark VIe tools.

How is firmware updated in the field?

Firmware can be updated through the Mark VIe system maintenance utility via the backplane or Ethernet port.

What is the typical control loop scan time achievable?

Less than 5 ms under full I/O load, depending on system configuration.

Does the board support redundant power feeds?

Yes, it accepts dual 24 V DC feeds for uninterrupted operation.

How are diagnostic alerts communicated to operators?

Through integrated LED indicators and system alarms transmitted to the Mark VIe HMI.

Can it be integrated into existing Mark VI systems?

Yes, with proper firmware and configuration, it can operate alongside legacy Mark VI equipment.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...