Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

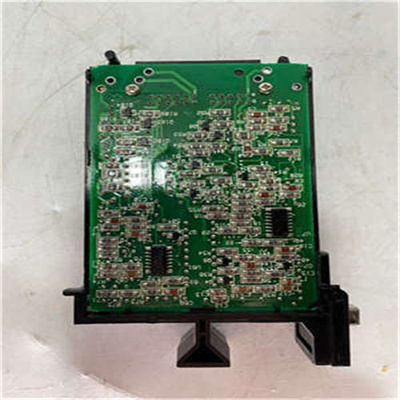

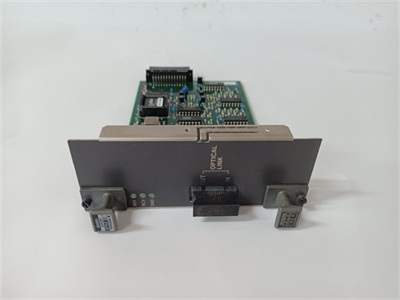

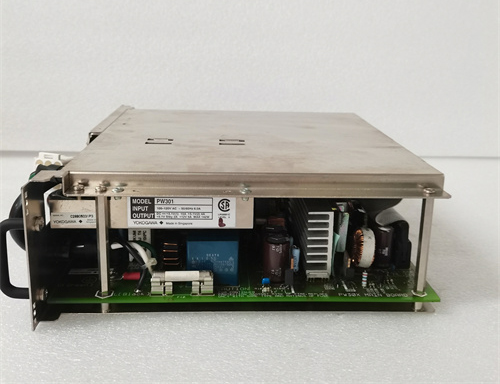

Yokogawa AAI835-h50 Analog I/O Module

Manufacturer:Yokogawa

Product Number:AAI835-h50

Product Type:Analog I/O Module

Origin:Japan

Dimensions:107.5 × 32.8 × 130 mm

Weight:0.3 kg

Views:98

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa AAI835-H50 is a sophisticated analog input/output module designed for industrial automation and process control systems. It facilitates the seamless integration of analog signals from field devices into control systems, ensuring precise data acquisition and control operations. This module is part of Yokogawa’s Field Control Unit (FCU) offerings, known for their reliability and performance in various industrial applications.

Technical Specifications

| Specification | Details |

|---|---|

| Model Number | AAI835-H50 |

| Number of Channels | 4 analog inputs / 4 analog outputs (isolated) |

| Input Signal Range | 4 to 20 mA |

| Output Signal Range | 4 to 20 mA |

| Allowable Input Current | Up to 25 mA |

| Withstanding Voltage | 500 V AC between input/output and system; 500 V AC between channels |

| Input Resistance (Power ON) | 290 Ω (at 20 mA) to 450 Ω (at 4 mA) |

| Input Resistance (Power OFF) | 500 kΩ or larger |

| Accuracy | Input: ±16 µA; Output: ±48 µA |

| Dimensions (H x W x D) | 107.5 × 32.8 × 130 mm |

| Weight | 0.3 kg |

| Operating Temperature Range | -20°C to 70°C |

| Storage Temperature Range | -40°C to 85°C |

| Humidity Range | 5% to 95% RH (non-condensing) |

| Certifications | CE, UL, CSA |

Applications

The Yokogawa AAI835-H50 analog I/O module is utilized in various industrial automation scenarios, including:

Process Control Systems: Monitoring and controlling analog signals from sensors and actuators in industries such as oil and gas, chemical, and pharmaceuticals.

Data Acquisition Systems: Collecting analog data for analysis and monitoring purposes in manufacturing and research facilities.

Industrial Automation: Integrating with PLCs and DCS systems to automate processes and improve operational efficiency.

Energy Management: Supervising power distribution and consumption metrics in utilities and renewable energy plants.

Water Treatment Facilities: Overseeing pump and valve statuses, ensuring optimal operation of water treatment processes.

Advantages

High Reliability: Ensures consistent performance in industrial environments.

Isolated Channels: Provides electrical isolation between channels, enhancing system safety and signal integrity.

Fast Response Time: With a data update period of 10 ms, it ensures timely processing of analog signals.

Compact Design: Space-efficient, suitable for various installation setups.

Flexible Connectivity: Supports multiple connection types, including pressure clamp terminals and MIL connector cables.

FAQs

1. What is the primary function of the AAI835-H50 module?

The AAI835-H50 serves as an analog input/output module, allowing industrial automation systems to receive and transmit analog signals for monitoring and control purposes.

2. How many input and output channels does this module support?

It supports 4 isolated analog input channels and 4 isolated analog output channels, facilitating the connection of multiple devices.

3. What types of input and output signals are compatible?

The module accommodates 4 to 20 mA analog signals for both inputs and outputs, offering flexibility in system design.

4. Can the module handle higher input currents?

Yes, the module can handle input currents up to 25 mA, ensuring compatibility with various industrial sensors.

5. What is the data update period of the AAI835-H50?

The module has a data update period of 10 ms, allowing for timely processing of analog signals.

6. How does the module ensure signal integrity?

The AAI835-H50 utilizes isolated channels for both inputs and outputs, ensuring protection against electrical noise and interference.

7. Is the module compatible with other PLC systems?

The AAI835-H50 is specifically designed for use with Yokogawa’s CENTUM VP and CENTUM CS distributed control systems and may not be compatible with other PLC systems.

8. What are the operating temperature parameters?

The module operates effectively within a temperature range of -20°C to 70°C, suitable for various industrial environments.

9. How is the module mounted within the system?

It is designed for easy installation within Yokogawa’s control system racks, ensuring seamless integration.

10. What are the operating conditions for the AAI835-H50?

This module operates within an industrial temperature range of -20°C to 70°C, with a storage temperature range of -40°C to 85°C. It is also designed to function effectively in humid environments with a humidity range of 5% to 95% RH (non-condensing).

Yokogawa AAI835-h50 Analog I/O Module

Manufacturer:Yokogawa

Product Number:AAI835-h50

Product Type:Analog I/O Module

Origin:Japan

Dimensions:107.5 × 32.8 × 130 mm

Weight:0.3 kg

Views:98

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa AAI835-H50 is a sophisticated analog input/output module designed for industrial automation and process control systems. It facilitates the seamless integration of analog signals from field devices into control systems, ensuring precise data acquisition and control operations. This module is part of Yokogawa’s Field Control Unit (FCU) offerings, known for their reliability and performance in various industrial applications.

Technical Specifications

| Specification | Details |

|---|---|

| Model Number | AAI835-H50 |

| Number of Channels | 4 analog inputs / 4 analog outputs (isolated) |

| Input Signal Range | 4 to 20 mA |

| Output Signal Range | 4 to 20 mA |

| Allowable Input Current | Up to 25 mA |

| Withstanding Voltage | 500 V AC between input/output and system; 500 V AC between channels |

| Input Resistance (Power ON) | 290 Ω (at 20 mA) to 450 Ω (at 4 mA) |

| Input Resistance (Power OFF) | 500 kΩ or larger |

| Accuracy | Input: ±16 µA; Output: ±48 µA |

| Dimensions (H x W x D) | 107.5 × 32.8 × 130 mm |

| Weight | 0.3 kg |

| Operating Temperature Range | -20°C to 70°C |

| Storage Temperature Range | -40°C to 85°C |

| Humidity Range | 5% to 95% RH (non-condensing) |

| Certifications | CE, UL, CSA |

Applications

The Yokogawa AAI835-H50 analog I/O module is utilized in various industrial automation scenarios, including:

Process Control Systems: Monitoring and controlling analog signals from sensors and actuators in industries such as oil and gas, chemical, and pharmaceuticals.

Data Acquisition Systems: Collecting analog data for analysis and monitoring purposes in manufacturing and research facilities.

Industrial Automation: Integrating with PLCs and DCS systems to automate processes and improve operational efficiency.

Energy Management: Supervising power distribution and consumption metrics in utilities and renewable energy plants.

Water Treatment Facilities: Overseeing pump and valve statuses, ensuring optimal operation of water treatment processes.

Advantages

High Reliability: Ensures consistent performance in industrial environments.

Isolated Channels: Provides electrical isolation between channels, enhancing system safety and signal integrity.

Fast Response Time: With a data update period of 10 ms, it ensures timely processing of analog signals.

Compact Design: Space-efficient, suitable for various installation setups.

Flexible Connectivity: Supports multiple connection types, including pressure clamp terminals and MIL connector cables.

FAQs

1. What is the primary function of the AAI835-H50 module?

The AAI835-H50 serves as an analog input/output module, allowing industrial automation systems to receive and transmit analog signals for monitoring and control purposes.

2. How many input and output channels does this module support?

It supports 4 isolated analog input channels and 4 isolated analog output channels, facilitating the connection of multiple devices.

3. What types of input and output signals are compatible?

The module accommodates 4 to 20 mA analog signals for both inputs and outputs, offering flexibility in system design.

4. Can the module handle higher input currents?

Yes, the module can handle input currents up to 25 mA, ensuring compatibility with various industrial sensors.

5. What is the data update period of the AAI835-H50?

The module has a data update period of 10 ms, allowing for timely processing of analog signals.

6. How does the module ensure signal integrity?

The AAI835-H50 utilizes isolated channels for both inputs and outputs, ensuring protection against electrical noise and interference.

7. Is the module compatible with other PLC systems?

The AAI835-H50 is specifically designed for use with Yokogawa’s CENTUM VP and CENTUM CS distributed control systems and may not be compatible with other PLC systems.

8. What are the operating temperature parameters?

The module operates effectively within a temperature range of -20°C to 70°C, suitable for various industrial environments.

9. How is the module mounted within the system?

It is designed for easy installation within Yokogawa’s control system racks, ensuring seamless integration.

10. What are the operating conditions for the AAI835-H50?

This module operates within an industrial temperature range of -20°C to 70°C, with a storage temperature range of -40°C to 85°C. It is also designed to function effectively in humid environments with a humidity range of 5% to 95% RH (non-condensing).

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...