Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

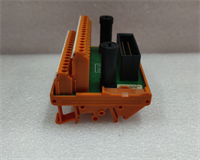

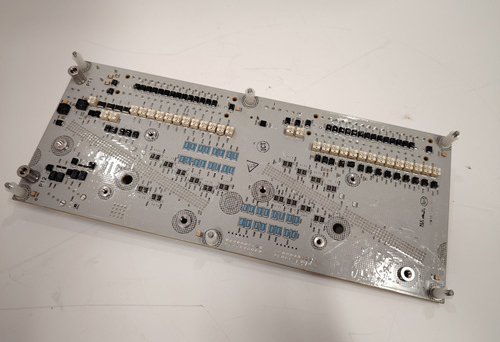

Honeywell 900C51-0243-00 C50 CPU Module

Manufacturer:Honeywell

Product Number:900C51-0243-00

Product Type:C50 CPU Module

Origin:USA

Dimensions:137 x 35.6 x 137.16 mm

Weight:0.18 kg

Views:51

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

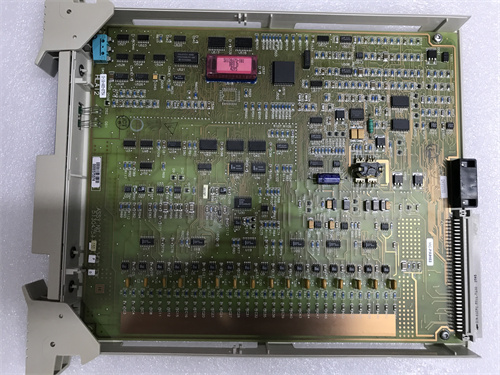

The Honeywell 900C51-0243-00 C50 CPU Module is a core processing unit developed for the Honeywell HC900 Hybrid Control System. As the central intelligence of the control rack, this CPU module executes logic, sequencing, batch control, and advanced regulatory functions. Designed for industrial-grade automation, the C50 CPU combines the features of a PLC and DCS into a single platform, enabling unified control for both discrete and continuous processes.

Its robust processing capacity, high-speed communication, and integrated redundancy options make it ideal for mission-critical industries. With modular scalability, it can handle thousands of I/O points, ensuring long-term flexibility and future expansion for plant operations.

Product Specifications

| Parameter | Description |

|---|---|

| Model | Honeywell 900C51-0243-00 (C50 CPU Module) |

| Product Type | Control CPU for HC900 Hybrid Control System |

| Processor | 32-bit industrial-grade CPU |

| Memory | 64 MB RAM, 32 MB Flash for programs and data |

| I/O Capacity | Supports up to 8,000 I/O points with expansion modules |

| Networking | Ethernet (10/100 Mbps), Modbus TCP/IP, peer-to-peer communication |

| Control Functions | Logic, PID loop control, sequencing, batch management |

| Scan Time | Minimum 10 ms (application dependent) |

| Redundancy | Supports CPU redundancy with automatic switchover |

| Diagnostic Features | Built-in watchdog timer, event logging, LED fault indicators |

| Power Supply Requirement | 24 VDC (18–32 VDC operating range) |

| Operating Temperature | 0 to 60 °C |

| Storage Temperature | -20 to 70 °C |

| Relative Humidity | 5% to 95% non-condensing |

| Compliance | CE, UL, CSA, IEC/EN 61131 |

| Dimensions | 137 x 35.6 x 137.16 mm |

| Weight | 0.18 kg |

Product Applications

The 900C51-0243-00 C50 CPU Module is a versatile industrial controller that can be deployed across many industries. Typical applications include:

Power & Utilities – Boiler management, auxiliary control, and turbine support systems.

Oil & Gas / Petrochemicals – Gas compression, refining units, and process safety applications.

Pharmaceutical Manufacturing – Batch processing, sterilization, and controlled environment automation.

Food & Beverage Industry – Recipe-based production, fermentation, and packaging automation.

Water & Wastewater – Treatment plant automation, pumping systems, and chemical dosing.

Metals & Mining – Furnace operation, rolling mill sequencing, and plant interlocks.

Product Advantages

High Capacity Processing – Handles complex applications with up to 8,000 I/O points.

Unified Platform – Combines process, batch, and logic control in a single controller.

Fast Performance – Quick scan times ensure precise and stable process response.

Redundancy Ready – Full CPU redundancy capability with automatic failover.

Scalable Architecture – Modular design allows step-by-step system expansion.

Strong Communication – Ethernet and Modbus TCP/IP ensure open connectivity.

Rugged Reliability – Designed for harsh industrial environments with long lifecycle support.

Advanced Diagnostics – Built-in monitoring, watchdog, and event logging features for high system availability.

FAQ

What type of CPU architecture does the 900C51-0243-00 use?

It uses a 32-bit industrial-grade CPU optimized for deterministic control tasks.

How much memory is available for user programs?

It provides 64 MB of RAM and 32 MB of Flash memory for applications and data storage.

Does the C50 CPU module support redundancy?

Yes, it supports full CPU redundancy with automatic switchover in the event of failure.

What communication protocols are supported?

The module supports Ethernet 10/100 Mbps, Modbus TCP/IP, and peer-to-peer networking.

What is the maximum I/O capacity supported by this CPU?

Up to 8,000 I/O points can be connected through expansion racks and modules.

What is the typical scan cycle time?

The scan cycle can reach as low as 10 ms, depending on application complexity.

Can this module be integrated with Honeywell Experion® systems?

Yes, it is fully compatible with Experion PKS for extended supervisory control and data acquisition.

Does it support batch and sequencing functions?

Yes, the CPU natively supports batch processing, sequencing, and PID control.

What diagnostic features are included?

Built-in watchdog timer, event logging, and fault status indicators are included.

How does the system handle communication redundancy?

The CPU supports redundant Ethernet communication and failover networking.

Honeywell 900C51-0243-00 C50 CPU Module

Manufacturer:Honeywell

Product Number:900C51-0243-00

Product Type:C50 CPU Module

Origin:USA

Dimensions:137 x 35.6 x 137.16 mm

Weight:0.18 kg

Views:51

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell 900C51-0243-00 C50 CPU Module is a core processing unit developed for the Honeywell HC900 Hybrid Control System. As the central intelligence of the control rack, this CPU module executes logic, sequencing, batch control, and advanced regulatory functions. Designed for industrial-grade automation, the C50 CPU combines the features of a PLC and DCS into a single platform, enabling unified control for both discrete and continuous processes.

Its robust processing capacity, high-speed communication, and integrated redundancy options make it ideal for mission-critical industries. With modular scalability, it can handle thousands of I/O points, ensuring long-term flexibility and future expansion for plant operations.

Product Specifications

| Parameter | Description |

|---|---|

| Model | Honeywell 900C51-0243-00 (C50 CPU Module) |

| Product Type | Control CPU for HC900 Hybrid Control System |

| Processor | 32-bit industrial-grade CPU |

| Memory | 64 MB RAM, 32 MB Flash for programs and data |

| I/O Capacity | Supports up to 8,000 I/O points with expansion modules |

| Networking | Ethernet (10/100 Mbps), Modbus TCP/IP, peer-to-peer communication |

| Control Functions | Logic, PID loop control, sequencing, batch management |

| Scan Time | Minimum 10 ms (application dependent) |

| Redundancy | Supports CPU redundancy with automatic switchover |

| Diagnostic Features | Built-in watchdog timer, event logging, LED fault indicators |

| Power Supply Requirement | 24 VDC (18–32 VDC operating range) |

| Operating Temperature | 0 to 60 °C |

| Storage Temperature | -20 to 70 °C |

| Relative Humidity | 5% to 95% non-condensing |

| Compliance | CE, UL, CSA, IEC/EN 61131 |

| Dimensions | 137 x 35.6 x 137.16 mm |

| Weight | 0.18 kg |

Product Applications

The 900C51-0243-00 C50 CPU Module is a versatile industrial controller that can be deployed across many industries. Typical applications include:

Power & Utilities – Boiler management, auxiliary control, and turbine support systems.

Oil & Gas / Petrochemicals – Gas compression, refining units, and process safety applications.

Pharmaceutical Manufacturing – Batch processing, sterilization, and controlled environment automation.

Food & Beverage Industry – Recipe-based production, fermentation, and packaging automation.

Water & Wastewater – Treatment plant automation, pumping systems, and chemical dosing.

Metals & Mining – Furnace operation, rolling mill sequencing, and plant interlocks.

Product Advantages

High Capacity Processing – Handles complex applications with up to 8,000 I/O points.

Unified Platform – Combines process, batch, and logic control in a single controller.

Fast Performance – Quick scan times ensure precise and stable process response.

Redundancy Ready – Full CPU redundancy capability with automatic failover.

Scalable Architecture – Modular design allows step-by-step system expansion.

Strong Communication – Ethernet and Modbus TCP/IP ensure open connectivity.

Rugged Reliability – Designed for harsh industrial environments with long lifecycle support.

Advanced Diagnostics – Built-in monitoring, watchdog, and event logging features for high system availability.

FAQ

What type of CPU architecture does the 900C51-0243-00 use?

It uses a 32-bit industrial-grade CPU optimized for deterministic control tasks.

How much memory is available for user programs?

It provides 64 MB of RAM and 32 MB of Flash memory for applications and data storage.

Does the C50 CPU module support redundancy?

Yes, it supports full CPU redundancy with automatic switchover in the event of failure.

What communication protocols are supported?

The module supports Ethernet 10/100 Mbps, Modbus TCP/IP, and peer-to-peer networking.

What is the maximum I/O capacity supported by this CPU?

Up to 8,000 I/O points can be connected through expansion racks and modules.

What is the typical scan cycle time?

The scan cycle can reach as low as 10 ms, depending on application complexity.

Can this module be integrated with Honeywell Experion® systems?

Yes, it is fully compatible with Experion PKS for extended supervisory control and data acquisition.

Does it support batch and sequencing functions?

Yes, the CPU natively supports batch processing, sequencing, and PID control.

What diagnostic features are included?

Built-in watchdog timer, event logging, and fault status indicators are included.

How does the system handle communication redundancy?

The CPU supports redundant Ethernet communication and failover networking.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...