Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

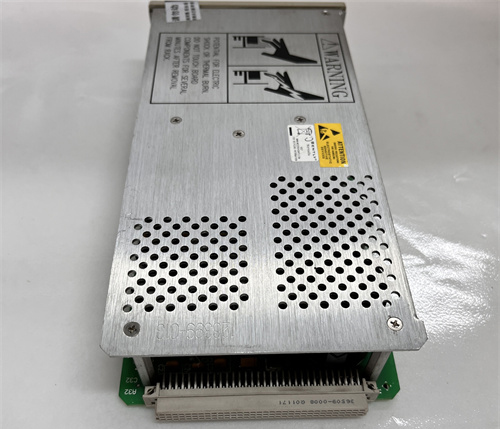

Bently Nevada 3500/77M-03-00 176449-07 Reciprocating Cylinder Pressure Monitor

Manufacturer:Bently Nevada

Product Number:3500/77M-03-00 176449-07

Product Type:Reciprocating Cylinder Pressure Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91kg

Views:19

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/77M-03-00 Reciprocating Cylinder Pressure Monitor (part number 176449-07) is an advanced condition monitoring module designed to provide precise and continuous measurement of cylinder pressure in reciprocating machinery. This module plays a vital role in detecting abnormal combustion events, mechanical faults, and operational inefficiencies in reciprocating compressors and engines.

Built for integration within the trusted Bently Nevada 3500 monitoring system, this module collects and processes real-time pressure data, offering comprehensive diagnostics and early warning capabilities. It supports enhanced machinery protection strategies by facilitating timely maintenance actions and preventing catastrophic failures.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 3500/77M-03-00 |

| Part Number | 176449-07 |

| Function | Reciprocating Cylinder Pressure Monitor |

| Input Type | Analog pressure signals from cylinder sensors |

| Number of Channels | Multiple cylinder pressure inputs (system dependent) |

| Output | Digital communication with 3500 rack system |

| Operating Voltage | 24 V DC nominal |

| Power Consumption | Approximately 3 W |

| Response Time | Real-time processing, typically < 10 ms |

| Operating Temperature | -40°C to +85°C |

| Storage Temperature | -55°C to +105°C |

| Humidity | 0-95% non-condensing |

| Dimensions | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Mounting | 3500 Series Rack Mount |

| Safety Certification | Meets relevant industrial safety standards |

| Communication Interface | Proprietary 3500 rack communication |

Applications

This module is ideal for:

-

Monitoring cylinder pressure in reciprocating compressors and engines

-

Detecting abnormal combustion events such as misfires and detonation

-

Assessing mechanical condition and integrity of reciprocating machinery

-

Supporting predictive maintenance and condition-based monitoring programs

-

Enhancing operational safety and reliability in petrochemical plants, power generation, and other industrial facilities

Advantages

Accurate Measurement: Delivers precise cylinder pressure readings critical for diagnostics.

Fast Response: Real-time data acquisition and processing enable immediate detection of faults.

Multiple Inputs: Supports numerous cylinder pressure inputs for comprehensive monitoring.

Robust Industrial Design: Engineered for harsh operating conditions including vibration and temperature extremes.

Seamless System Integration: Compatible with Bently Nevada 3500 rack and system for centralized monitoring.

Improved Safety: Enables early detection of combustion and mechanical anomalies to prevent failures.

Reliable Performance: Built on proven Bently Nevada technology with extensive industry adoption.

Frequently Asked Questions (FAQ)

What types of sensors are compatible with this module?

Supports standard analog pressure sensors used for cylinder pressure measurement.

How many channels does the module support?

The number of inputs varies depending on system configuration; designed to handle multiple cylinders.

What is the typical response time?

Under 10 milliseconds for real-time monitoring.

Is the module suitable for use in hazardous environments?

Refer to overall system certifications; installation practices must comply with hazardous area requirements.

What power supply does the module require?

Powered by 24 V DC provided by the 3500 rack system.

Can this module detect combustion anomalies?

Yes, it identifies events such as misfires and detonation through pressure analysis.

What maintenance is necessary?

Periodic testing and sensor calibration recommended for optimal performance.

Does the module offer diagnostic feedback?

Yes, integrates with the 3500 system for comprehensive diagnostics.

What is the operational temperature range?

-40°C to +85°C.

What is the expected operational lifespan?

Typically exceeds 10 years with proper maintenance.

Bently Nevada 3500/77M-03-00 176449-07 Reciprocating Cylinder Pressure Monitor

Manufacturer:Bently Nevada

Product Number:3500/77M-03-00 176449-07

Product Type:Reciprocating Cylinder Pressure Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91kg

Views:19

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/77M-03-00 Reciprocating Cylinder Pressure Monitor (part number 176449-07) is an advanced condition monitoring module designed to provide precise and continuous measurement of cylinder pressure in reciprocating machinery. This module plays a vital role in detecting abnormal combustion events, mechanical faults, and operational inefficiencies in reciprocating compressors and engines.

Built for integration within the trusted Bently Nevada 3500 monitoring system, this module collects and processes real-time pressure data, offering comprehensive diagnostics and early warning capabilities. It supports enhanced machinery protection strategies by facilitating timely maintenance actions and preventing catastrophic failures.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 3500/77M-03-00 |

| Part Number | 176449-07 |

| Function | Reciprocating Cylinder Pressure Monitor |

| Input Type | Analog pressure signals from cylinder sensors |

| Number of Channels | Multiple cylinder pressure inputs (system dependent) |

| Output | Digital communication with 3500 rack system |

| Operating Voltage | 24 V DC nominal |

| Power Consumption | Approximately 3 W |

| Response Time | Real-time processing, typically < 10 ms |

| Operating Temperature | -40°C to +85°C |

| Storage Temperature | -55°C to +105°C |

| Humidity | 0-95% non-condensing |

| Dimensions | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Mounting | 3500 Series Rack Mount |

| Safety Certification | Meets relevant industrial safety standards |

| Communication Interface | Proprietary 3500 rack communication |

Applications

This module is ideal for:

-

Monitoring cylinder pressure in reciprocating compressors and engines

-

Detecting abnormal combustion events such as misfires and detonation

-

Assessing mechanical condition and integrity of reciprocating machinery

-

Supporting predictive maintenance and condition-based monitoring programs

-

Enhancing operational safety and reliability in petrochemical plants, power generation, and other industrial facilities

Advantages

Accurate Measurement: Delivers precise cylinder pressure readings critical for diagnostics.

Fast Response: Real-time data acquisition and processing enable immediate detection of faults.

Multiple Inputs: Supports numerous cylinder pressure inputs for comprehensive monitoring.

Robust Industrial Design: Engineered for harsh operating conditions including vibration and temperature extremes.

Seamless System Integration: Compatible with Bently Nevada 3500 rack and system for centralized monitoring.

Improved Safety: Enables early detection of combustion and mechanical anomalies to prevent failures.

Reliable Performance: Built on proven Bently Nevada technology with extensive industry adoption.

Frequently Asked Questions (FAQ)

What types of sensors are compatible with this module?

Supports standard analog pressure sensors used for cylinder pressure measurement.

How many channels does the module support?

The number of inputs varies depending on system configuration; designed to handle multiple cylinders.

What is the typical response time?

Under 10 milliseconds for real-time monitoring.

Is the module suitable for use in hazardous environments?

Refer to overall system certifications; installation practices must comply with hazardous area requirements.

What power supply does the module require?

Powered by 24 V DC provided by the 3500 rack system.

Can this module detect combustion anomalies?

Yes, it identifies events such as misfires and detonation through pressure analysis.

What maintenance is necessary?

Periodic testing and sensor calibration recommended for optimal performance.

Does the module offer diagnostic feedback?

Yes, integrates with the 3500 system for comprehensive diagnostics.

What is the operational temperature range?

-40°C to +85°C.

What is the expected operational lifespan?

Typically exceeds 10 years with proper maintenance.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...