Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

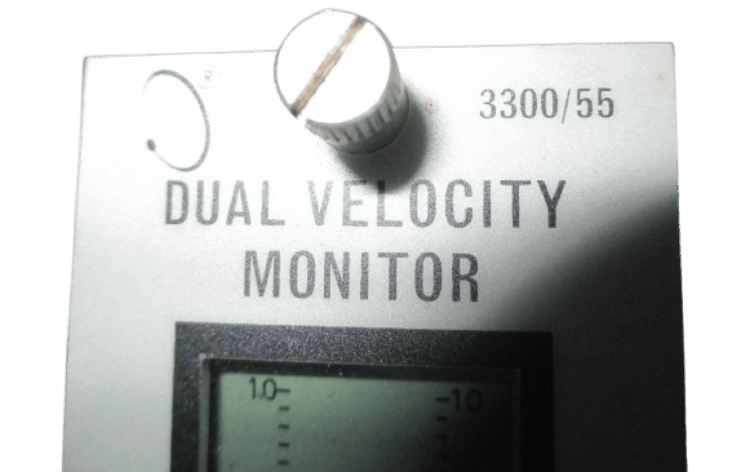

Bently Nevada 3300/55 Dual Velocity Monitor

Item Number:3300/55

Brand:Bently Nevada

Lead Time: In stock

Description:Dual Velocity Monitor

Payment: T/T

Product Description

Bently Nevada 3300/55 Dual Velocity Monitor is a device used for online monitoring of machinery vibration. It can be input by one or two Velomitor® sensors, the High Temperature Velomitor System (HTVS), or the Velocity Seismoprobe® sensor. No interface module is required and user-selectable settings are available. However, when measuring the casing for overall machine protection, the effectiveness of the measurement and the sensor installation issues must be considered.

Function & Features

- Dual Channel Monitoring: The 3300/55 provides continuous mechanical vibration monitoring on two channels.

- Multiple Sensors: The 3300/55 can receive signals from one or two Velomitor® sensors, High Temperature Velomitor Systems (HTVS), or Velocity Seismoprobe® sensors.

- Parameter Settings: The 3300/55 allows users to easily field program options such as high-pass and low-pass filter corner frequencies via plug-in jumpers.

Specifications

|

Parameter |

Details |

|

Input |

|

|

Sensitivity |

500 mV/in/s, 145 mV/in/s or 100 mV/in/s (jumper programmable) |

|

Power Consumption |

Nominal 1.5W |

|

Frequency Response |

3-10,000 Hz (180 - 600,000 cpm), nominal -3dB for velocity seismometer |

|

Filter Corner Frequencies |

- High-pass: Selectable from 450 frequencies (3-400 Hz / 180-24,000 cpm) |

|

- Low-pass: Selectable from 500 frequencies (24-3,000 Hz / 1,440-180,000 cpm) |

|

|

- Corner frequencies typically 3 dB below passband center frequency |

|

|

Output |

|

|

Recorder |

+4 mA to +20 mA, 0 Vdc to -10 Vdc, or +1 Vdc to +5 Vdc |

|

Recorder Accuracy |

±0.7% of signal for +4 to +20 mA |

|

±0.09 mA offset at +25°C (+77°F) |

|

Bently Nevada 3300/55 Dual Velocity Monitor

Item Number:3300/55

Brand:Bently Nevada

Lead Time: In stock

Description:Dual Velocity Monitor

Payment: T/T

Product Description

Bently Nevada 3300/55 Dual Velocity Monitor is a device used for online monitoring of machinery vibration. It can be input by one or two Velomitor® sensors, the High Temperature Velomitor System (HTVS), or the Velocity Seismoprobe® sensor. No interface module is required and user-selectable settings are available. However, when measuring the casing for overall machine protection, the effectiveness of the measurement and the sensor installation issues must be considered.

Function & Features

- Dual Channel Monitoring: The 3300/55 provides continuous mechanical vibration monitoring on two channels.

- Multiple Sensors: The 3300/55 can receive signals from one or two Velomitor® sensors, High Temperature Velomitor Systems (HTVS), or Velocity Seismoprobe® sensors.

- Parameter Settings: The 3300/55 allows users to easily field program options such as high-pass and low-pass filter corner frequencies via plug-in jumpers.

Specifications

|

Parameter |

Details |

|

Input |

|

|

Sensitivity |

500 mV/in/s, 145 mV/in/s or 100 mV/in/s (jumper programmable) |

|

Power Consumption |

Nominal 1.5W |

|

Frequency Response |

3-10,000 Hz (180 - 600,000 cpm), nominal -3dB for velocity seismometer |

|

Filter Corner Frequencies |

- High-pass: Selectable from 450 frequencies (3-400 Hz / 180-24,000 cpm) |

|

- Low-pass: Selectable from 500 frequencies (24-3,000 Hz / 1,440-180,000 cpm) |

|

|

- Corner frequencies typically 3 dB below passband center frequency |

|

|

Output |

|

|

Recorder |

+4 mA to +20 mA, 0 Vdc to -10 Vdc, or +1 Vdc to +5 Vdc |

|

Recorder Accuracy |

±0.7% of signal for +4 to +20 mA |

|

±0.09 mA offset at +25°C (+77°F) |

|

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...